Large-scale device circuit breaker suitable for high-temperature working environment of factory

A technology for working environment and large-scale equipment, applied to circuits, parts of protective switches, electrical components, etc., can solve problems affecting the magnetic force of short-circuit coils in circuit breakers, increasing production costs, and bimetallic sheets of circuit breakers are bent by heat, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

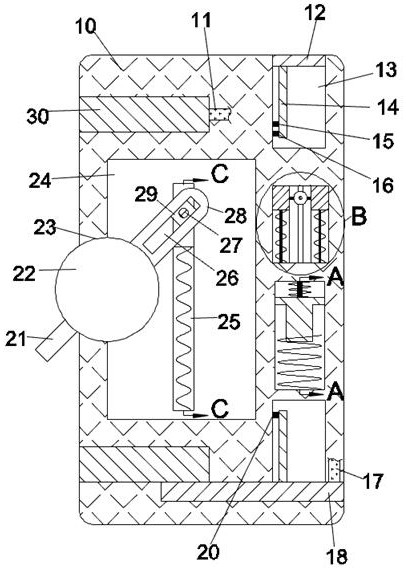

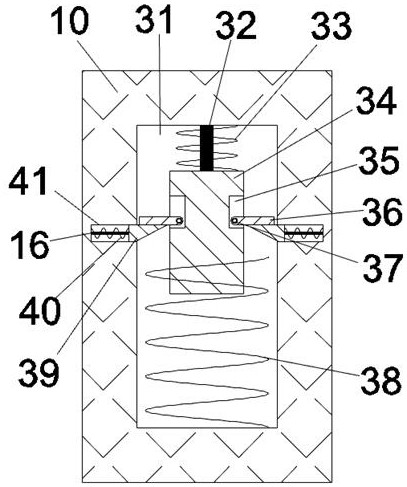

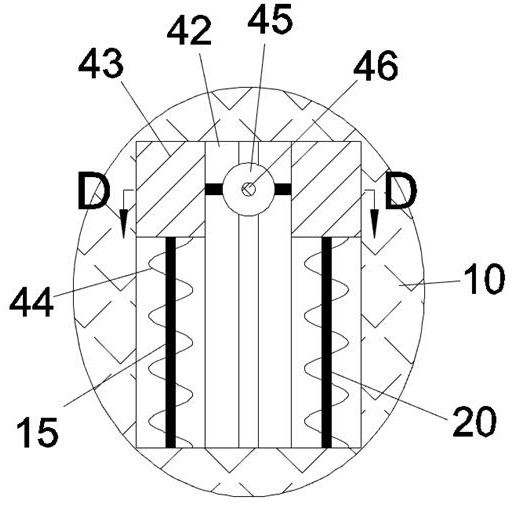

[0023] Combine below Figure 1-9 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0024] combined with Figure 1-9 The above-mentioned large-scale equipment circuit breaker suitable for the high-temperature working environment of the factory includes a circuit breaker housing 10, and the circuit breaker housing 10 is provided with a circuit connection mechanism, an external connection mechanism, an overload protection mechanism and a short-circuit protection mechanism, The external connection mechanism is connected to the external wires, the circuit connection mechanism switches the internal circuit and cooperates with the external connection mechanism to make the circuit form a circuit, and the overload protection mechanism controls the circuit connection mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com