A micro-controlled hydraulic fine crusher

A hydraulic, fine crushing technology, applied in the field of mining machinery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

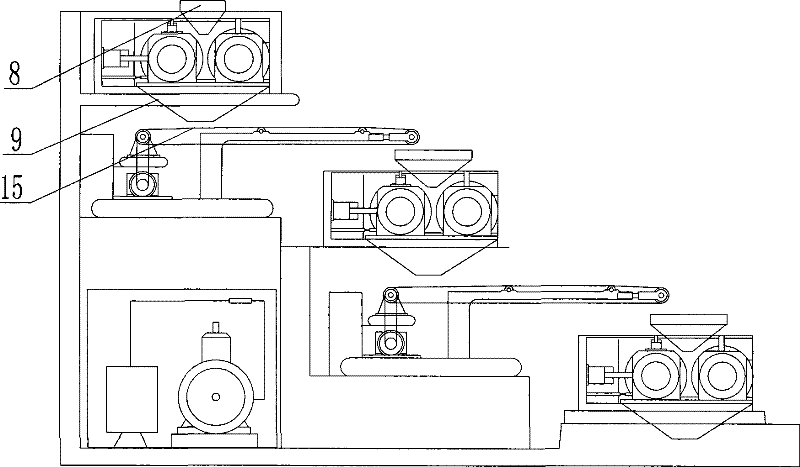

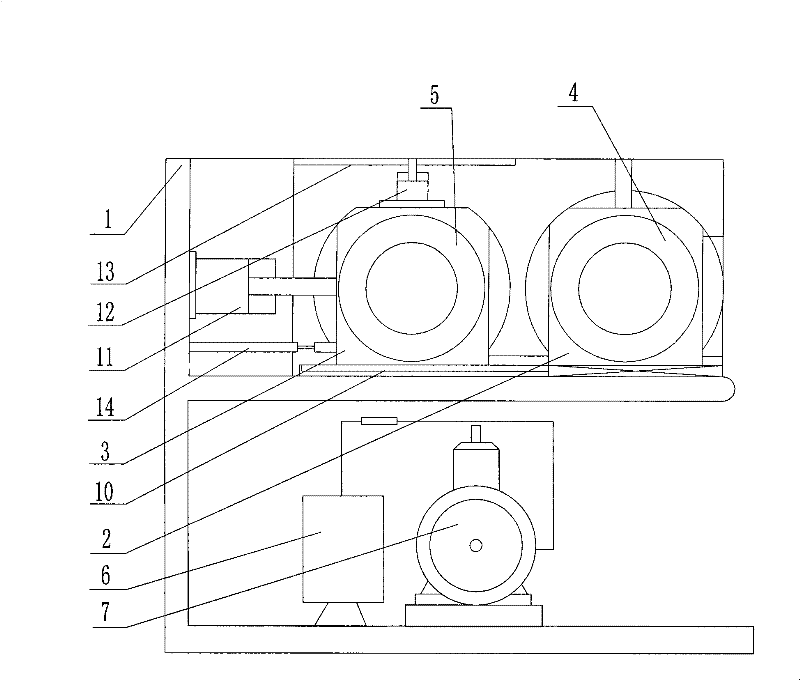

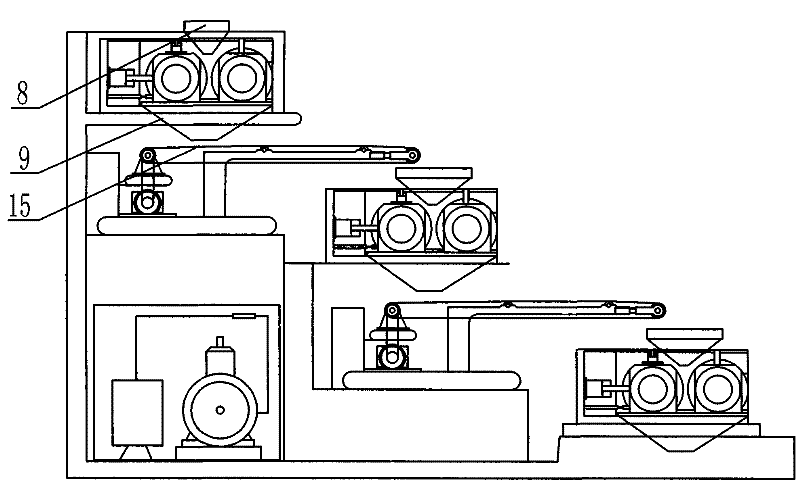

[0020] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0021] Depend on figure 1 , 2 It can be seen that the micro-controlled hydraulic type fine crusher of the present invention includes a frame 1, a fixed bearing seat 2, a movable bearing seat 3, a pair of squeezing rollers 4 and 5, an oil tank 6, an oil pump 7, a feed hopper 8, an outlet Hopper 9, track 10, gap adjustment hydraulic cylinder 11, compaction hydraulic cylinder 12, beam track 13, gap adjustment push rod 14, conveyor belt 15. A feed hopper 8 is arranged on the upper frame of the paired squeeze rollers 4 and 5, and a discharge hopper 9 is arranged on the lower frame of the paired squeeze rollers 4 and 5. The fixed bearing seat 2 is fixed on the frame 1 by bolts, and a track 10 is arranged on the frame, and the movable bearing seat 3 is placed in the track 10 and can slide along the track. The paired extrusion rollers 4 and 5 are respectively Installed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com