Convenient rotor oil injection structure of large-scale motor

A technology of large motor and oil injection structure, which is applied in the manufacture of motor generators, electrical components, electromechanical devices, etc. It can solve the problems of waste of manpower and material resources, slow oil injection and maintenance, and poor use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

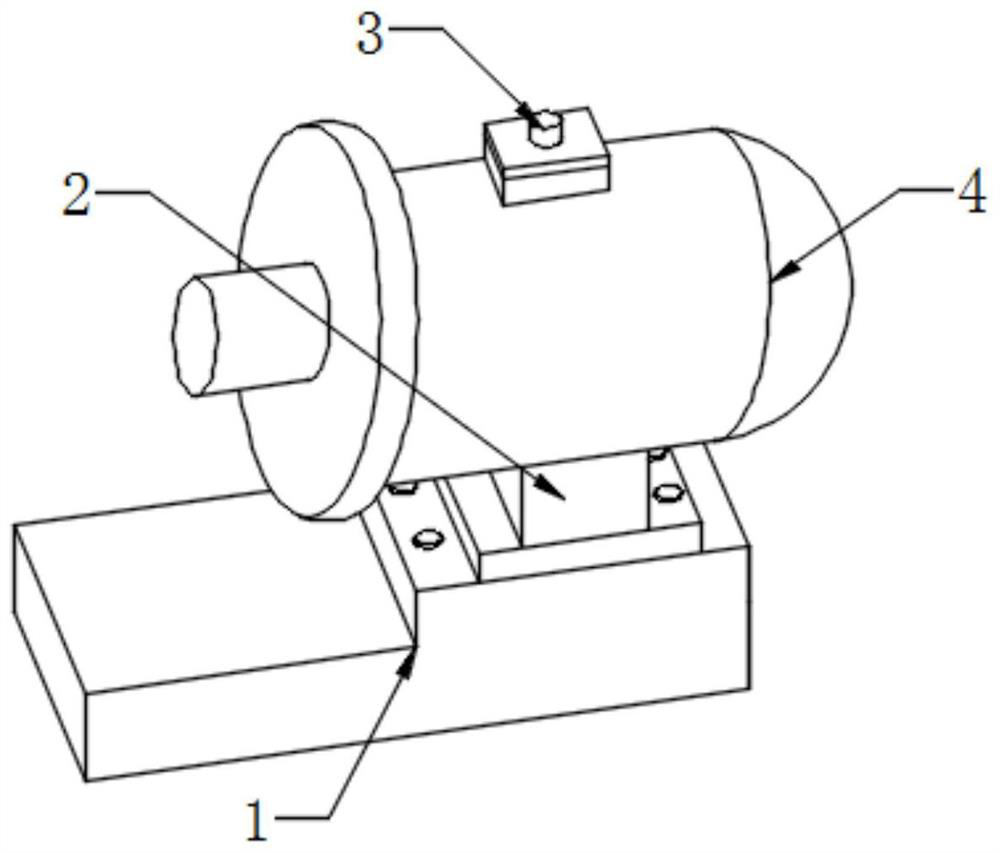

[0020] see Figure 1-Figure 4 , the present invention provides a technical solution: a large-scale motor convenient rotor oiling structure, including a support seat 1, a connecting seat 2, an oiling assembly 3 and a motor body 4, the lower end of the motor body 4 is equipped with a connecting seat 2, a connecting seat 2 A supporting seat 1 is installed on the lower end surface, and an oil filling assembly 3 is arranged on the upper side of the motor main body 4 .

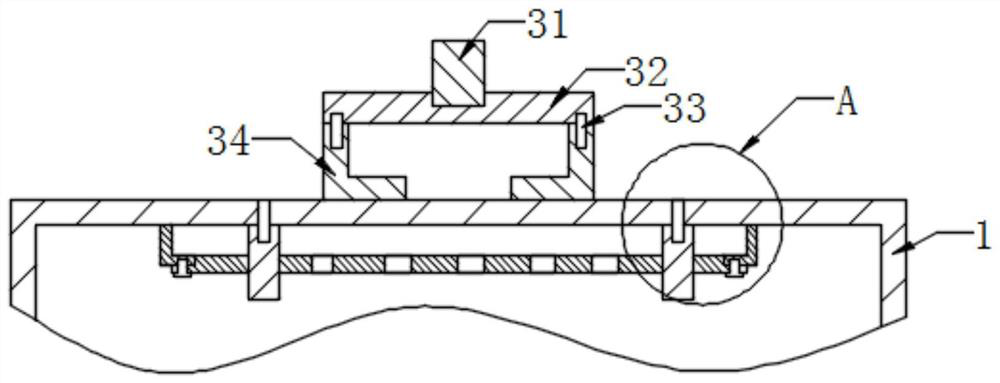

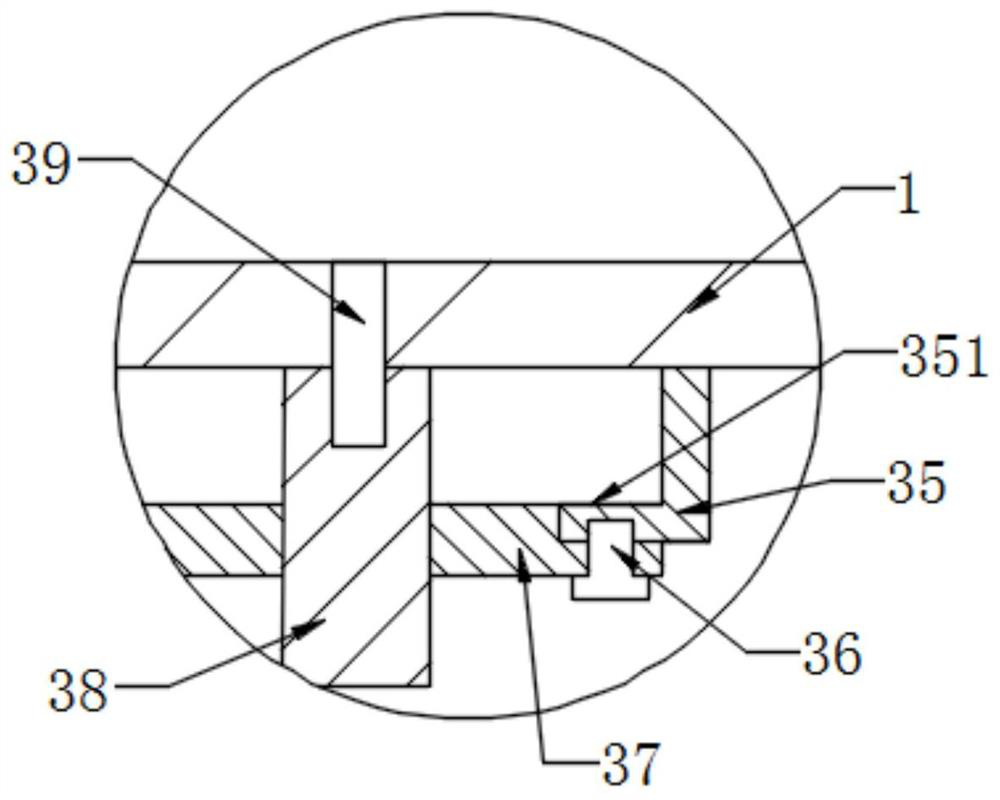

[0021] The oil filling assembly 3 includes a pull handle 31, a cover plate 32, a fixed block 33, an oil filling box 34, a sealing plate 35, a bolt 36, an oil filling pipe 37, a bracket 38 and a threaded post 39, and the upper end of the motor body 4 is fixed with an oil filling box 34....

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap