Chip mounter for integrated circuit processing

A technology of integrated circuits and placement machines, which is applied in the directions of printed circuits, printed circuit manufacturing, and assembling printed circuits with electrical components, which can solve problems such as clogging of suction nozzles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

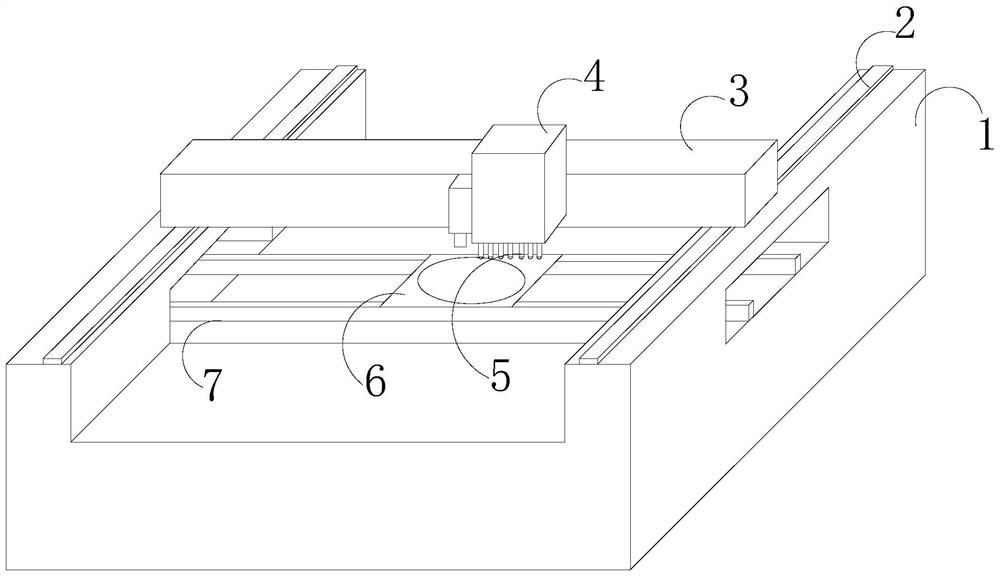

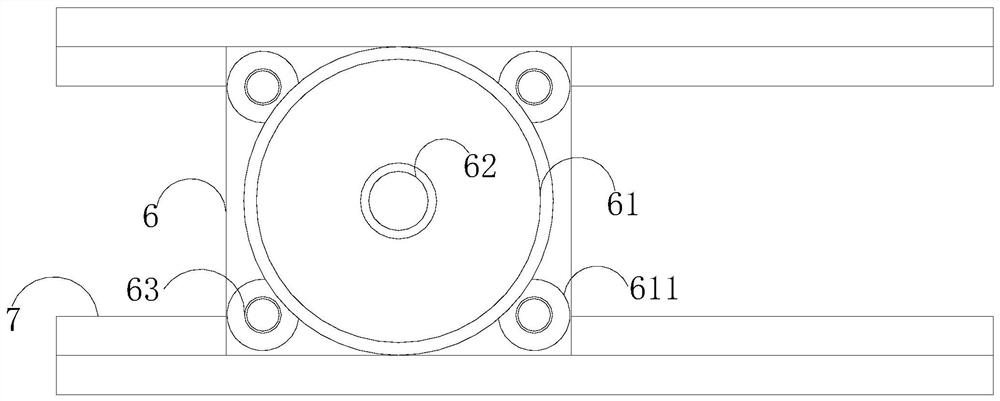

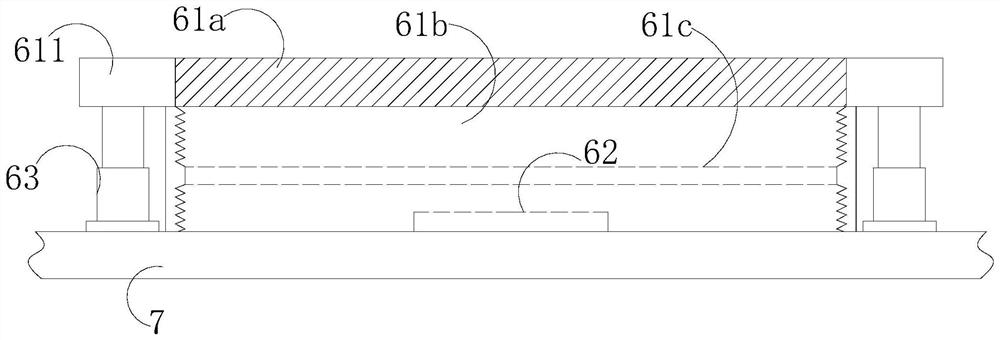

[0027] like Figure 1-Figure 6 As shown, the present invention provides a placement machine for integrated circuit processing, and its structure includes a base 1, a slide rail 2, a beam 3, a placement head 4, a suction nozzle 5, a workbench 6, and a fixing seat 7. The machine A slide rail 2 is provided on the seat 1, and the crossbeam 3 is movably fitted on the slide rail 2. The crossbeam 3 is equipped with a mounting head 4, and the bottom of the mounting head 4 is provided with a suction nozzle 5, and the suction nozzle 5 is facing the workbench 6, the workbench 6 is set on the fixed base 7, the workbench 6 includes a protection device 61, a clamping base 62, and a lifting cylinder 63, and the protection device 61 is sleeved on the clamping base 62 periphery, the lifting cylinder 63 is mechanically connected with the protective device 61, the clamping base 62 is opposite to the suction nozzle 6 up and down, the protective device 61 is a circular structure, and the four corn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com