Electronic equipment

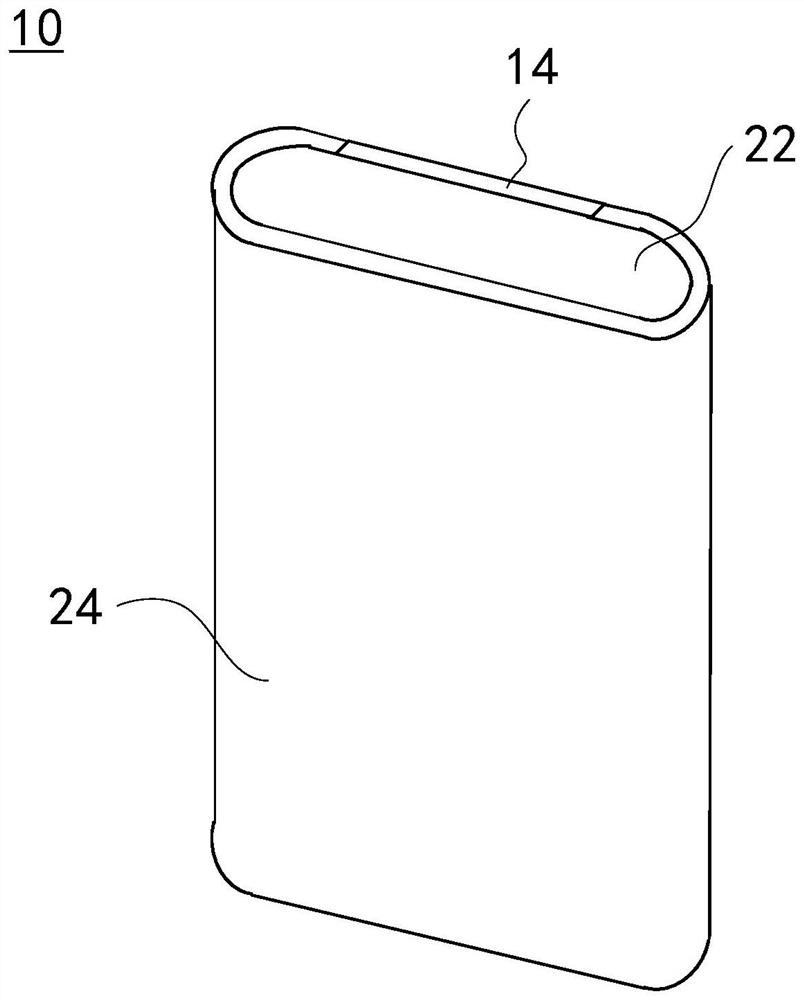

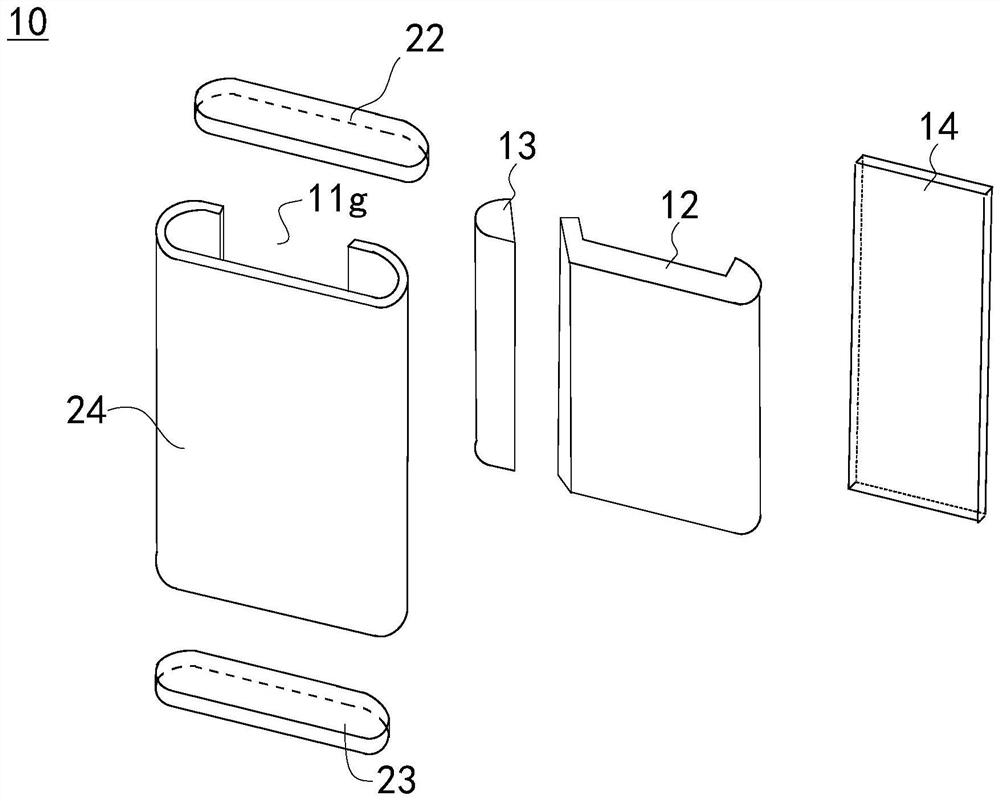

A technology for electronic equipment and sub-faces, which is applied in branch equipment, electrical equipment shells/cabinets/drawers, electrical components, etc., and can solve problems such as difficult assembly of shells and appearance parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] In Embodiment 1, by designing the middle frame as a split structure including the first housing 12 and the second housing 13, the first housing 12 and the second housing 13 can be respectively loaded into the housing of the curved screen module. cavity. This split-type middle frame design can meet the assembly requirements when the opening 11g between the first side part 111 and the second side part 113 in the curved screen module is relatively narrow, and the overall width of the middle frame is large, overcoming the traditional The difficulty in assembling the middle frame and the curved screen module with a large curvature facilitates the realization of a large viewing angle display design for the electronic device 10 .

[0080] Such as Figure 10 and Figure 11 As shown, in the second embodiment, the difference from the first embodiment above is that: the first engaging surface 12a is provided with a first engaging protrusion 121, and the second engaging surface 1...

Embodiment 2

[0083] In the second embodiment, the first housing 12 and the second housing 13 form a detachable connection through the engagement of the first locking protrusion 121 and the first locking groove 131, and the first housing 12 and the second housing 13 can be connected conveniently and reliably. The second casing 13 is fixedly installed in the receiving cavity of the curved screen module.

[0084] In other embodiments, the positions of the first locking protrusion 121 and the first locking groove 131 can be interchanged, that is, the first locking protrusion 121 is arranged on the second mating surface 13a of the second housing 13, and the first locking groove 131 is opened. on the first mating surface 12a of the first housing 12 . The structures of the first locking protrusion 121 and the first locking groove 131 are not limited to the above, but can be designed according to requirements, as long as the detachable connection can be realized. For example, the first protrusion...

Embodiment 6

[0093] In the sixth embodiment, through the cooperation between the first sub-surface 12a1 and the third sub-surface 13a1, and the engagement between the second engaging protrusion 123 and the second engaging groove 132, the first housing 12 and the second housing 13 can form a movable By disassembling and connecting, the first casing 12 and the second casing 13 can be conveniently and reliably fixedly installed in the storage cavity of the curved screen module.

[0094] In other embodiments, the positions of the second locking protrusion 123 and the second locking groove 132 can be interchanged, that is, the second locking protrusion 123 is arranged on the second mating surface 13a of the second housing 13, and the second locking groove 132 is opened. on the first mating surface 12a of the first housing 12 . The structure of the second locking protrusion 123 is not limited to the above, but can be designed as required, as long as the detachable connection can be realized. Fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com