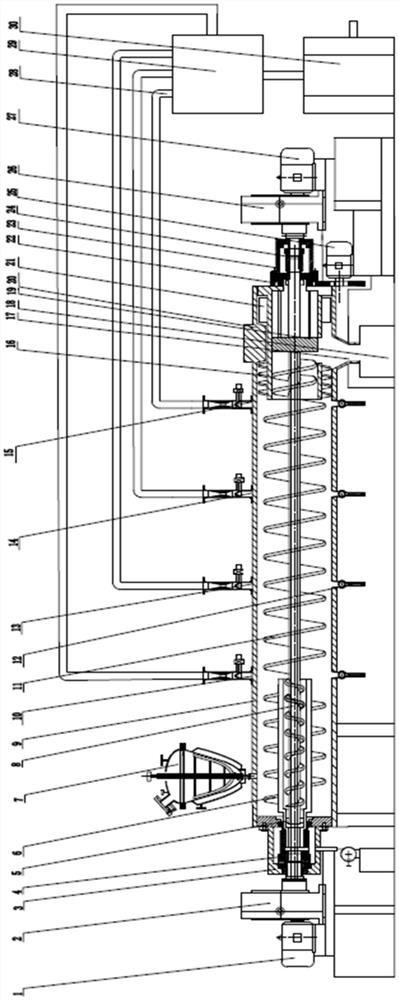

Three-stage differential double-helix synthesis cracking reaction equipment capable of accurately regulating and controlling physical properties

A cracking reaction and double helix technology, which is applied in chemical/physical/physicochemical fixed reactors, feeding devices, control/regulation processes, etc., can solve the problems that real-time detection of material parameters and precise control of materials cannot be realized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The reactor feeding device (7) allows the material to enter the barrel (9) into the left differential speed outer screw (6), and under the push of the left differential speed outer screw (6), the material is mixed and preheated while advancing, and at the same time some materials During the transportation process, the forward spiral anti-backflow thread (31) and the reverse spiral anti-backflow thread (32) of the main screw (8) enter from the left and right ends of the left differential outer screw (6). The role of the material not only realizes the differential cracking, but also prevents the material from flowing back to the main screw (8). Then the material enters the forward spiral compression cracking section (33) of the main screw (8). The material is fully preheated in the left differential outer screw (6) and then enters the forward screw compression cracking section (33) of the main screw (8) for rapid cracking.

[0029] First open the left outer screw motor (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com