Trundle support punching device and punching method

A technology of punching device and casters, which is applied in the field of punching devices, can solve the problems affecting the accuracy, affecting the normal use of facilities, tilting or even overturning, etc., to achieve the effect of ensuring the accuracy of hole positions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

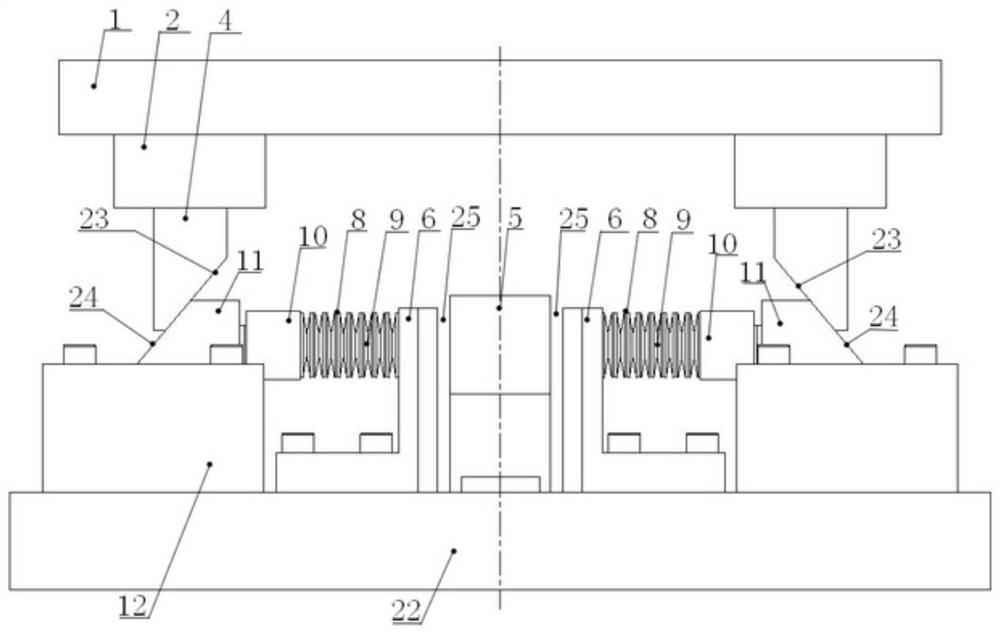

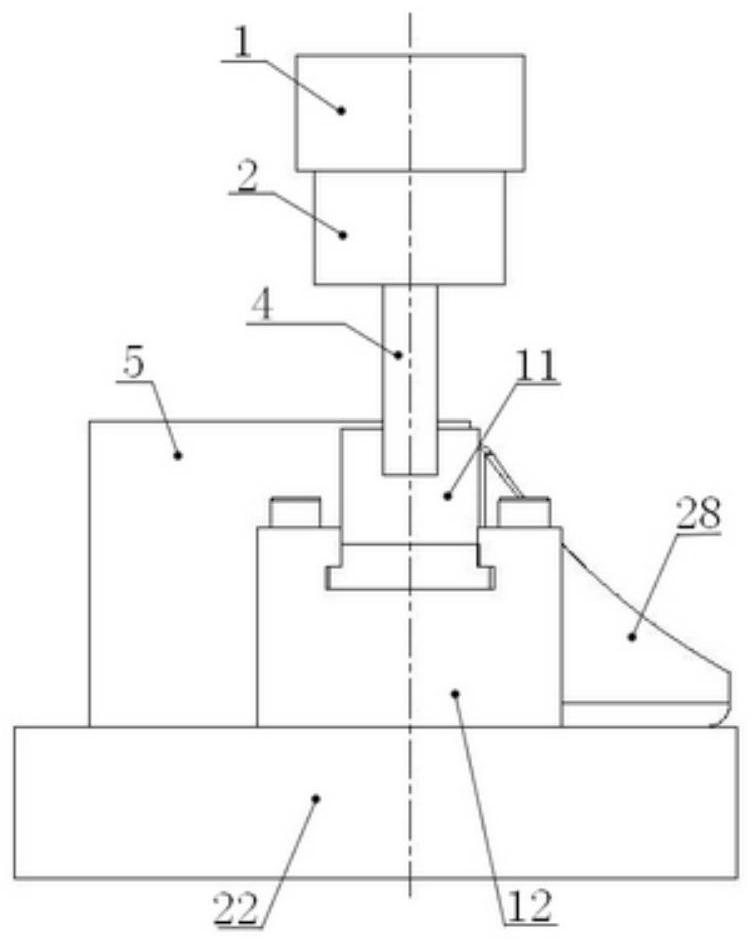

[0070] Such as Figure 2A-Figure 6 Shown is a caster bracket punching device, including: an upper base plate 1, a wedge 4, a fixing seat 5, a punching sleeve 6, a guide plate 7, a punch 9, an inclined slider 11 and a lower base plate 22.

[0071] Wherein, the upper base plate 1 and the lower base plate 22 are vertically opposite to each other, and the lower surface of the upper base plate 1 is fixedly equipped with two symmetrical wedges 4, the upper ends of the two wedges 4 are connected to the upper base plate 1, and the two inclined wedges The outer side of the lower end of the wedge 4 is longer than the inner side, and an inner slope 23 inclined inward is formed.

[0072] Wherein, the fixed seat 5 is fixedly connected with the lower base plate 22, and the left and right sides of the fixed seat 5 are respectively symmetrically installed with a guide plate 7, a punch 9, and an inclined slider 11 from near to far, defining the position of each element close to the fixed seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com