Magnetic force frame for clamping electric drill or pneumatic drill

A magnetic frame and pneumatic technology, applied in the field of magnetic frame, can solve problems such as high verticality requirements, complicated clamping of electric drills or pneumatic air drills, and inability to guarantee drilling quality, so as to achieve the effect of improving work efficiency and light volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

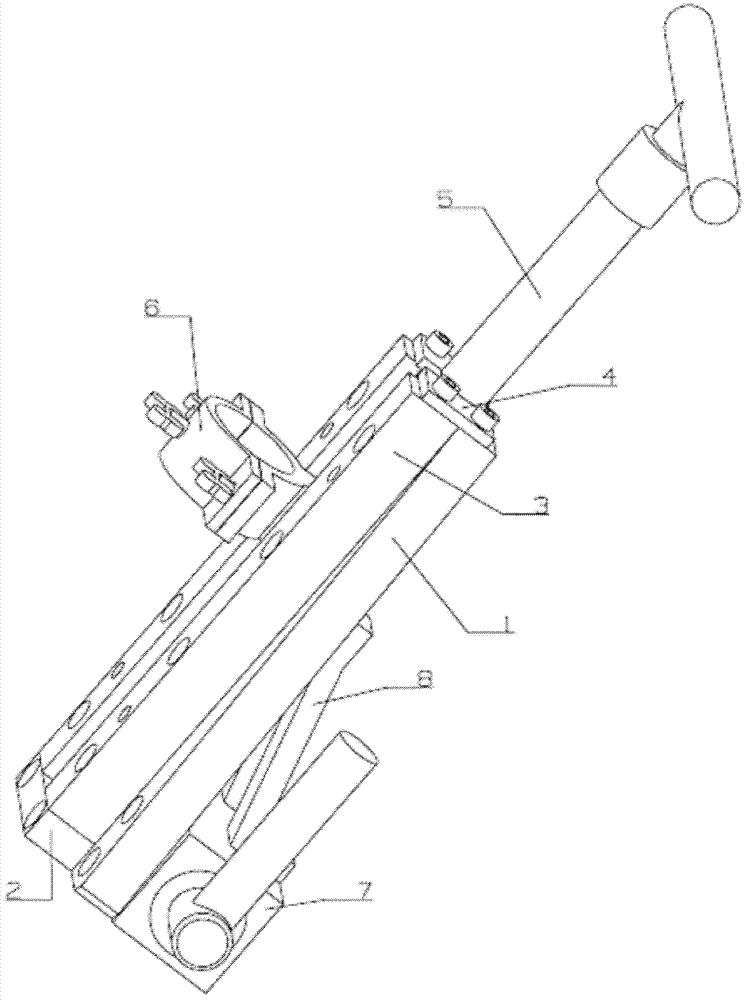

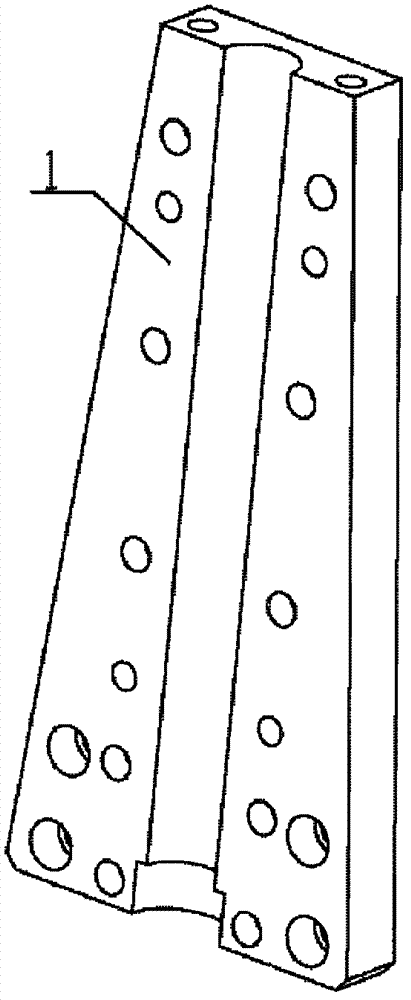

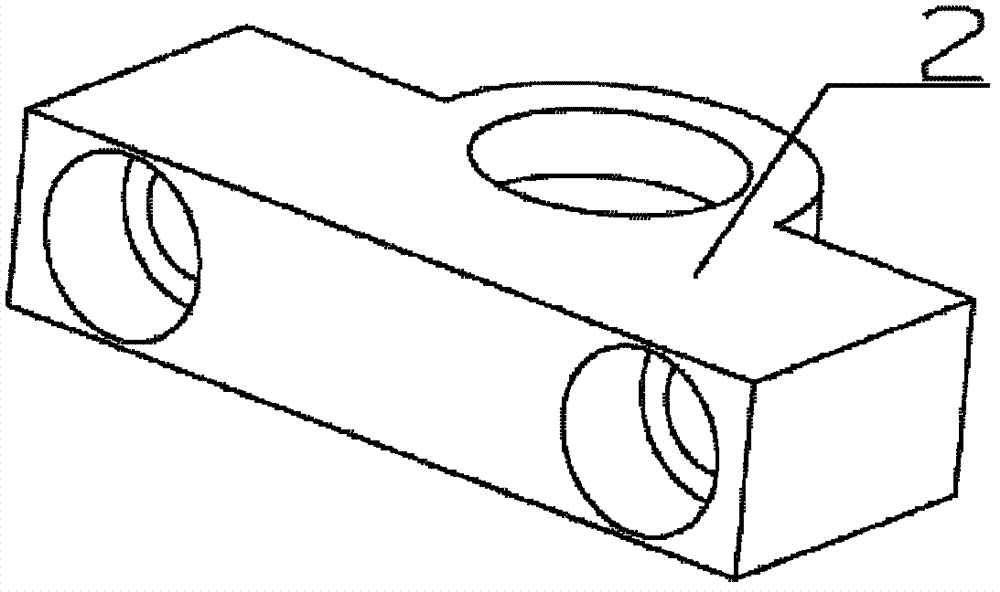

[0018] A magnetic frame for clamping an electric drill or a pneumatic air drill consists of a frame body 1, a base 2, two guide rails 3, a connecting cover plate 4, a lead screw 5, a clamping tool 6, a switchable permanent magnet 7 and two A reinforced bracket 8 is formed, the frame body 1 is a plate-shaped part, and the center of the frame body is provided with a semi-cylindrical through hole, and the upper and lower ends of the frame body 1 are respectively provided with screw holes; the base 2 is a cuboid with a semicircular convex edge, and the base 2 There is a round hole for setting up the screw, and two through holes are provided on the side of the base. The base 2 and the frame body 1 are connected and fixed by screws and the screw holes of the frame body 1; the cross-section of the two guide rails 3 is L-shaped and parallel. Set in pairs, the lower part and the upper end surface of the guide rail 3 are respectively provided with through holes, the bottom end of the gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com