Rapid drilling device attached to forming die

A technology of drilling device and forming die, applied in the direction of drilling dies for workpieces, etc., can solve the problems of high cost and long cycle, avoid special assembly tooling, improve quality and economic benefits, and ensure hole position accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

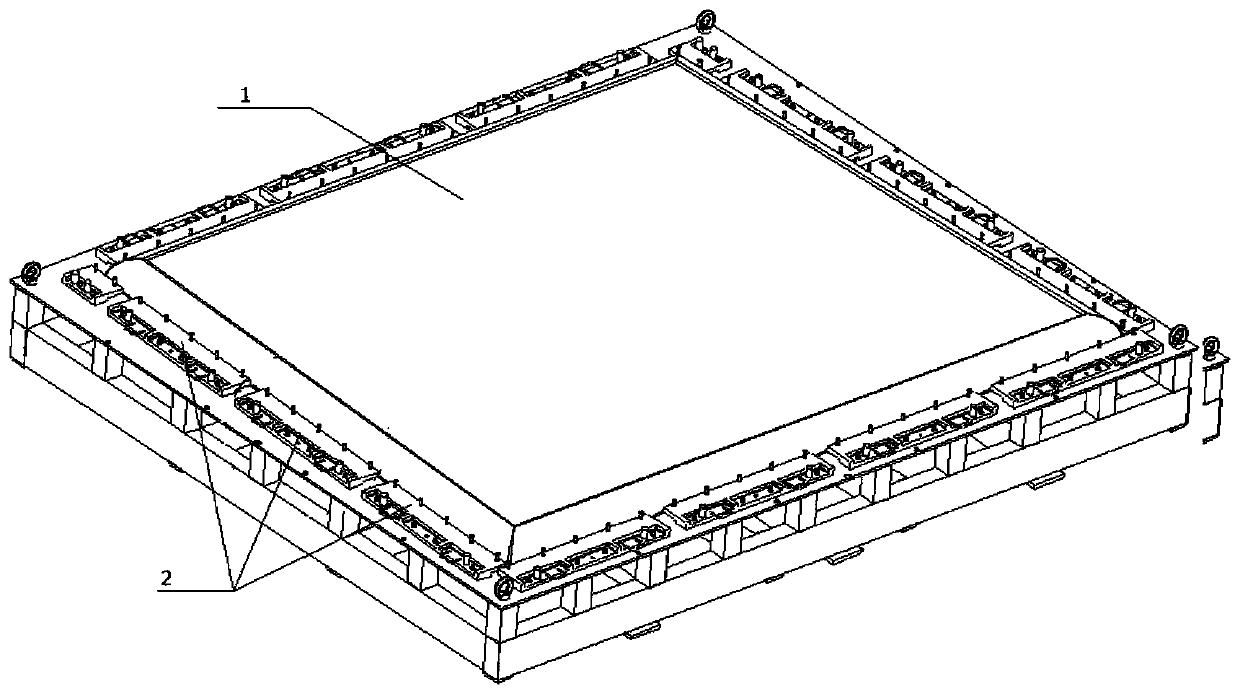

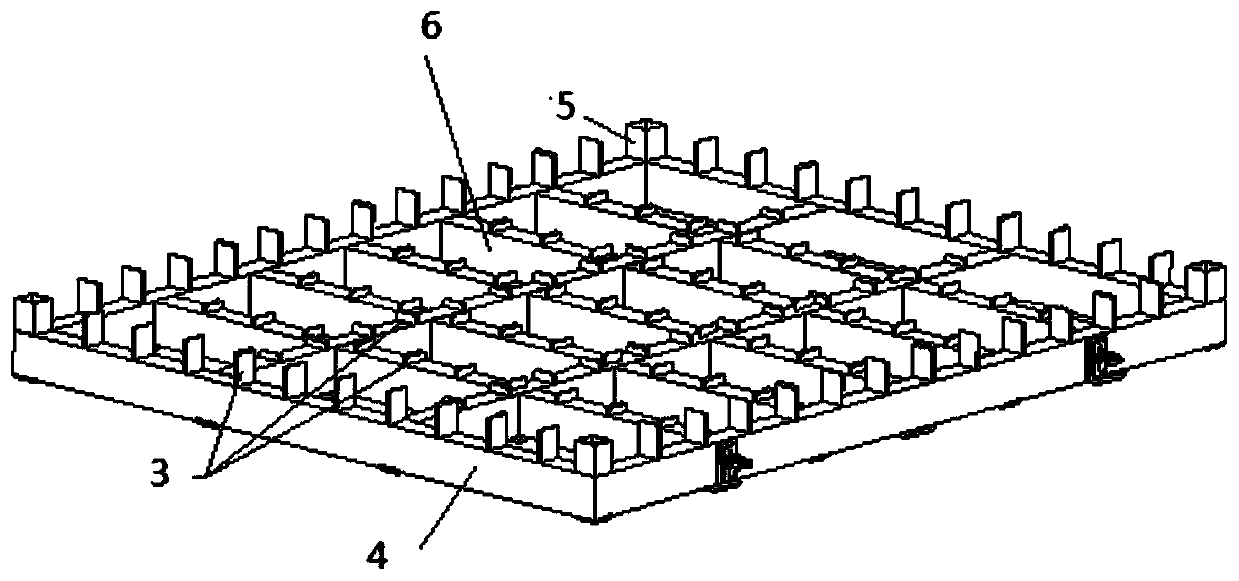

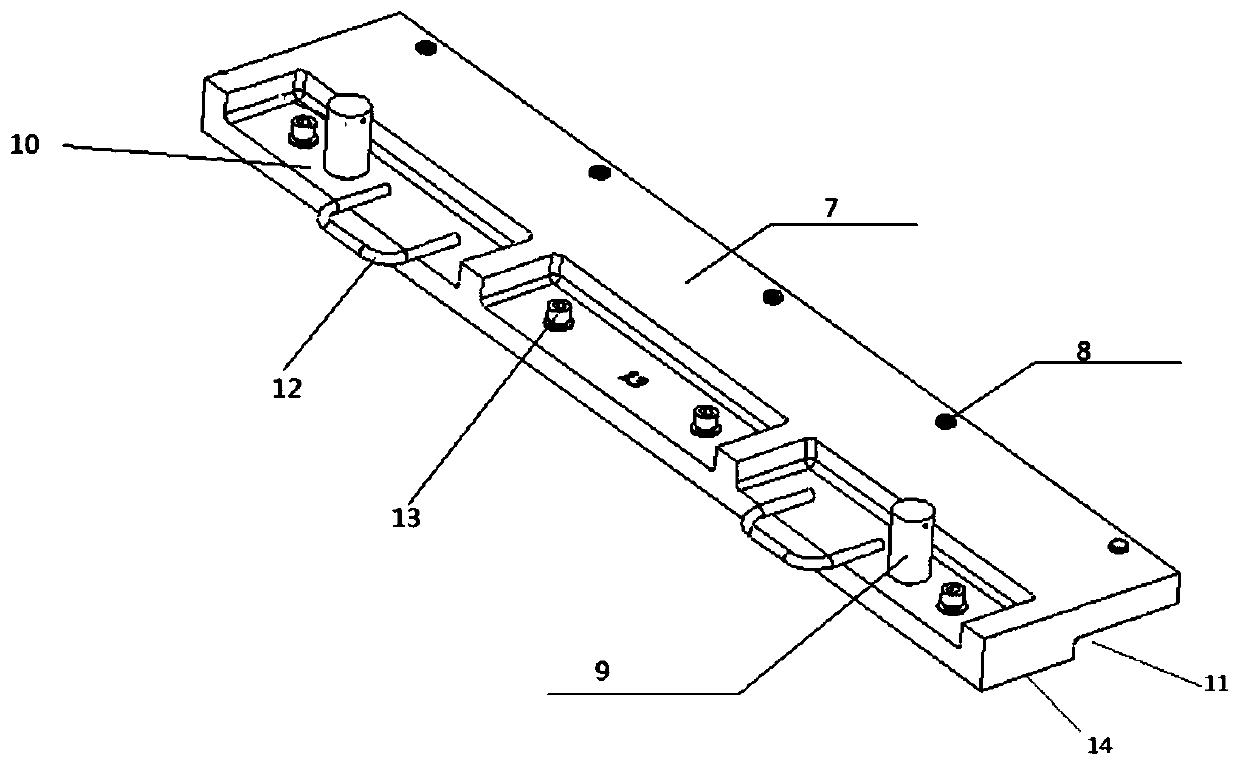

[0020] The present invention will be further introduced below in conjunction with the accompanying drawings. The present invention will be further described below in conjunction with the accompanying drawings. A fast drilling device attached to a molding die according to the present invention includes a base plate and a pattern plate 1 , support ring 4, support column 5, some support vertical plates 3, some drilling devices 2, described support ring 4 is arranged on the bottom plate, and described support ring 4 is provided with some reinforcing pipes 6, and described support The vertical plate 3 is arranged on the top of the support ring 4 and the reinforcing pipe 6, the described support column 5 is arranged on the top of the support ring 4, the described template 1 is arranged on the top of the support column 5 and the support vertical plate 3, and the described drilling The device 2 is evenly arranged along the edge of the template 1, and the drilling device 2 includes a po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com