Pipe jacking mold facilitating demolding of inner mold

An internal mold and demoulding technology, which is applied to molds, manufacturing tools, ceramic molding machines, etc., can solve problems such as troublesome and difficult demoulding of internal molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

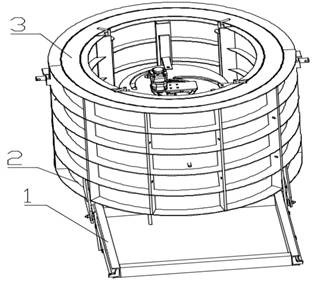

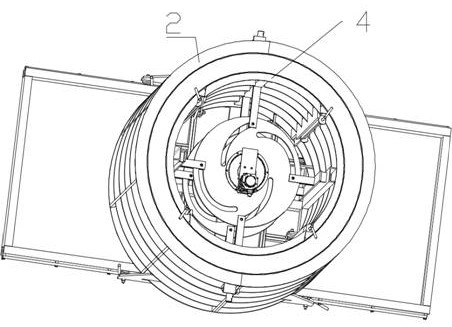

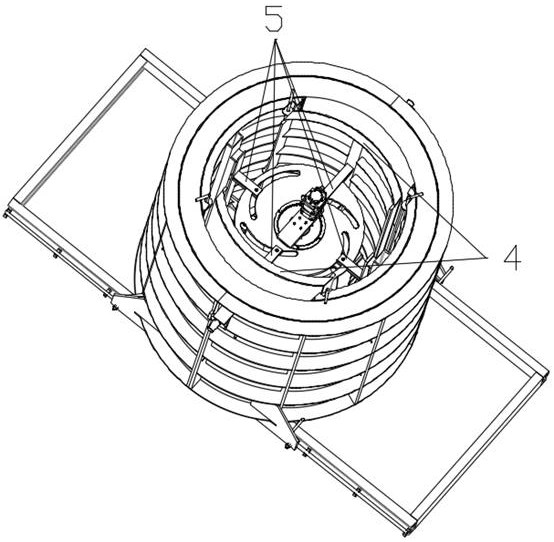

[0024] Example 1. If figure 1 As shown, a pipe jacking mold that facilitates demoulding of the inner mold includes a base 1 on which an outer mold 2 and an inner mold 3 are arranged, and the inner mold 3 is composed of four concentric arc-shaped plates 4 , the two groups of arc-shaped plates 4 are symmetrical and symmetrical to the center of the circle and the two groups are sequentially shrinked and demoulded. A connecting rod 5 is fixed in the middle of the inner side of the arc-shaped plate 4, and a rotating shaft connected to the connecting rod 5 is provided in the center of the inner mold 3. The inner mold receiving device is provided with a locking device at the joint of the arc plate 4 .

[0025] The rotary inner mold collecting device includes a fixed shaft 6 fixed on the base 1, the fixed shaft 6 is located at the center of the inner mold 3, and the upper and lower rotating discs 7 and 8 are fixed to the bearings at the upper and lower ends of the fixed shaft 6. , ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com