Construction method for underground continuous wall of near-sea pushing and filling area

A technology of underground diaphragm wall and construction method, which is applied in the direction of excavation, sheet pile wall, foundation structure engineering, etc., to achieve the effect of ensuring accuracy, strengthening strength and connection performance, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

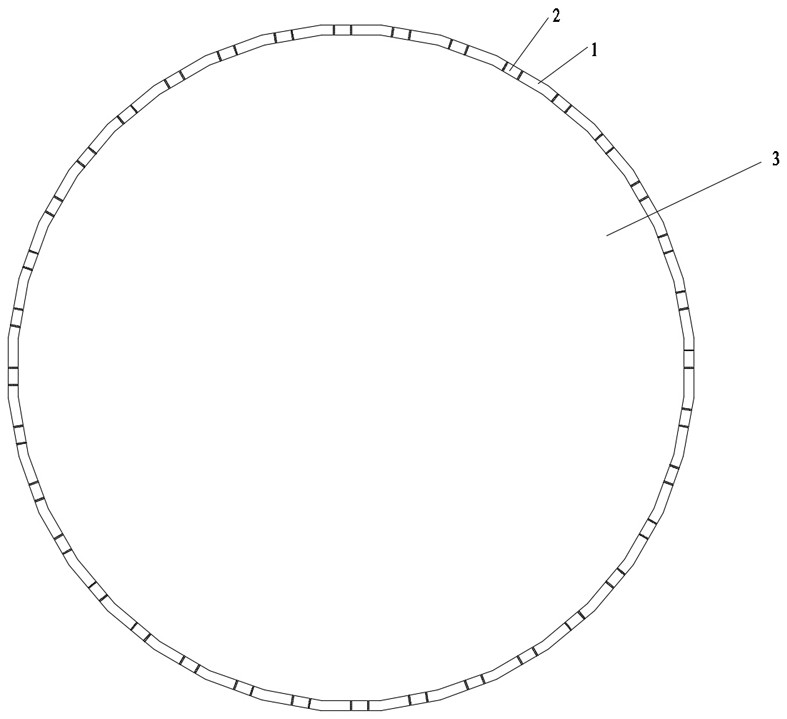

[0044] Taking an LNG liquefied natural gas project as an example, the project is located on the northeast coast of a certain bay, and is basically formed by land reclamation, with a land area of about 26 hectares. The foundation pit of the storage tank is a deep circular permanent foundation pit with an inner diameter of 100m and a depth of 50m; the upper part of the foundation pit is push-filled soil, and the lower part is slightly weathered granite; the enclosure structure adopts underground diaphragm walls without internal support. The underground diaphragm wall is 54-62m deep, and enters the slightly weathered granite 15-30m, and the rock strength reaches a maximum of 136Mpa.

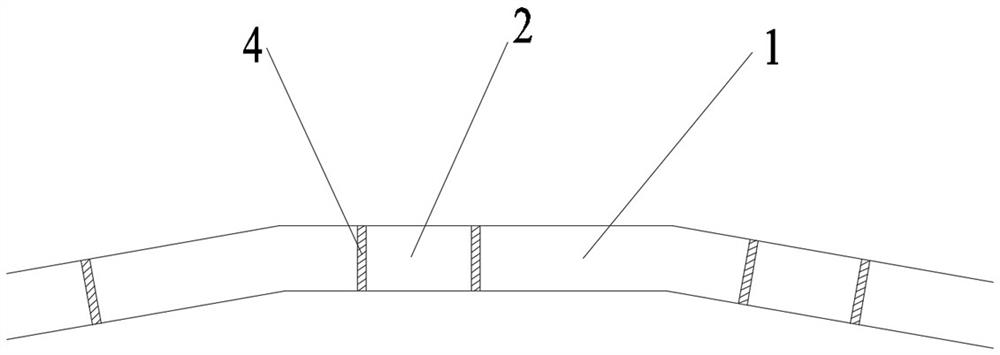

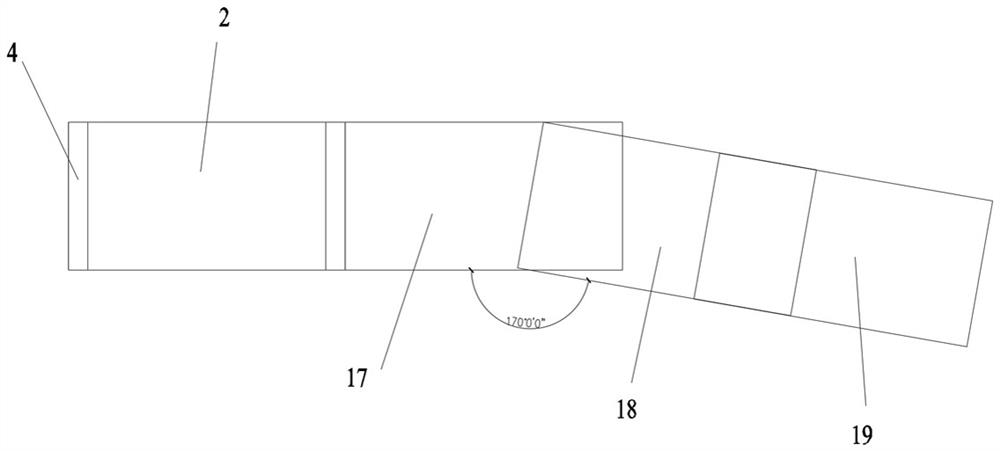

[0045] Such as Figure 1 to Figure 5 As shown, the underground diaphragm wall includes a type I connecting wall 1, a type II connecting wall 2 connected between the adjacent type I connecting walls 1, and a sleeve set between the type I connecting wall 1 and the type II connecting wall 2 Milling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com