Lifting hook type shot blasting machine

A shot blasting machine and hook technology, which is applied in the manufacturing field, can solve the problem that loading and unloading cannot be carried out at the same time, and achieve the effect of remarkable strengthening effect, easy maintenance and low noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

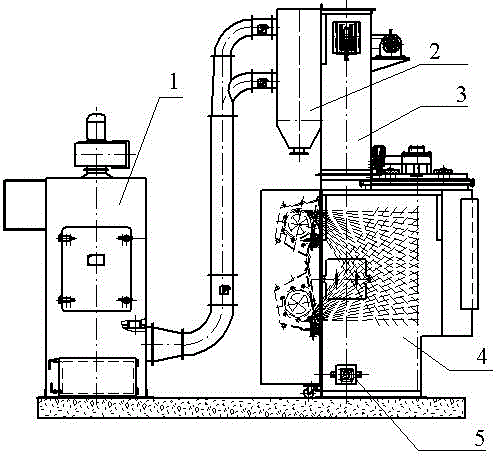

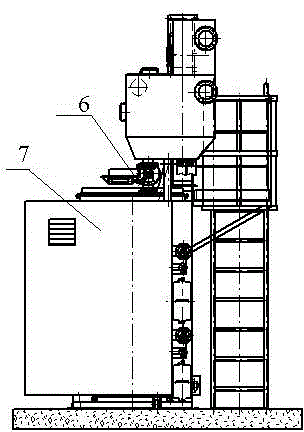

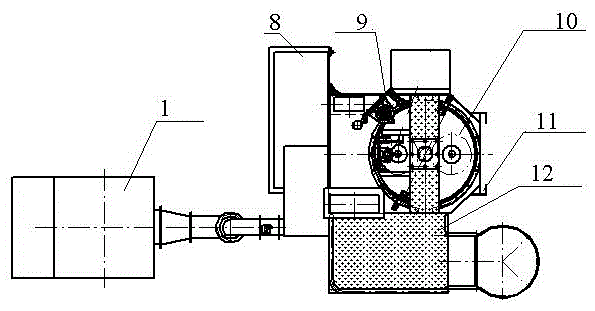

[0024] see Figure 1 to Figure 5 As shown, the present invention comprises a cleaning room 4, an electric control system, a dust collector 1, a separator 2, a hoist 3, a pill feeding system 6, and a screw conveying system 5, and the electric control system is responsible for the control and operation of the entire system, and the cleaning A hook turntable mechanism is provided in the chamber 4, and the screw conveying system 5 is located at the bottom of the cleaning chamber 4, and a hoist 3 is arranged on the side of the cleaning chamber 4, and a separator 2 is arranged on the side of the hoist 3, so that The separator 2 is connected with the dust collector 1 through a closed pipe, and a shot supply system 6 is provided on one side of the hook turntable mechanism. One shot blasting machine, two shot blasting machines are fixed on the switch type shot blasting door 7 at the rear of the chamber body, when the switch type shot blasting door 7 is opened and closed, the shot blast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com