Laser shock peening device of airplane blade tenon

A technology for laser shock strengthening and aircraft blades, which is applied in the field of laser shock strengthening devices for the falcon part of aircraft blades, and can solve problems such as the influence of processing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

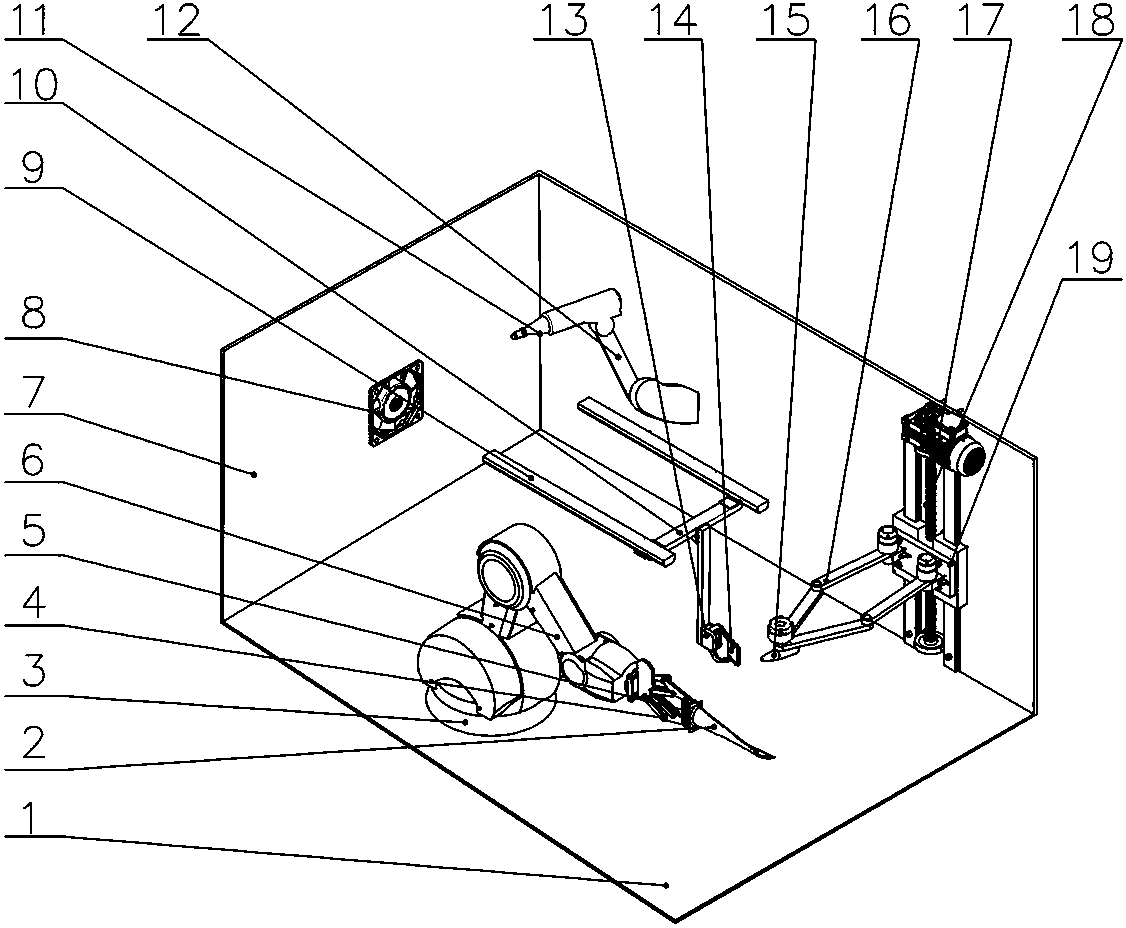

[0030] figure 1 The structure shown is a laser shock peening device for the falcon part of an aircraft blade that is relatively complete and suitable for automatic laser strengthening. It should be known that, for example, the falcon part 5 of the blade 2 often needs to be sprayed with absorbing paint, such as black paint, and then painted on it. Laser strengthening is performed, while the painting itself can be done separately.

[0031] Similarly, for example, the tooling 14 can also be made separately and assembled on the falcon portion 5 of the blade 2. Therefore, in the embodiments of the present invention, if a strong automatic completion rate is not considered, more Realization can assist configuration, but does not constitute a necessary technical feature.

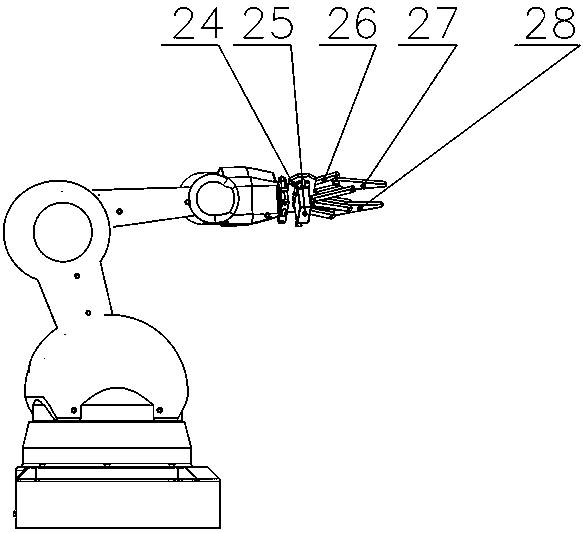

[0032] In the most basic implementation, it is a new constraint configuration compared to the traditional constraint form. As a basic laser shock peening device for the falcon part of an aircraft blade, it should a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com