A length measuring instrument for processing plastic products

A technology of length measurement and plastic products, applied in the direction of instruments, measuring devices, mechanical measuring devices, etc., can solve the problems of poor practicability, troublesome, large space occupied, etc., to achieve simple and convenient height adjustment, and avoid easy movement and occupation. small space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

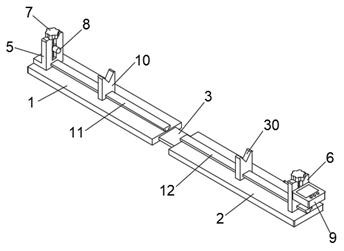

[0032] Such as figure 1 , 5As shown in . and 8, a length measuring instrument for processing plastic products includes a fixed mounting frame 5 and a mobile mounting frame 6. The fixed mounting frame 5 is fixed on the upper end of the No. 1 base plate 1 by screws and is located on the outside of the No. 1 guide rail 11. , the lower end of the mobile mounting frame 6 is provided with a mounting chute 25, and the mobile mounting frame 6 is slidably installed on the No. 2 guide rail 12 through the mounting chute 25 offered at its lower end. Mounting groove 21, two mounting grooves 21 penetrate the inner and outer ends of the fixed mounting frame 5 and the mobile mounting frame 6 respectively, and the upper ends of the fixed mounting frame 5 and the mobile mounting frame 6 are all provided with a No. 1 hole 22, two No. 1 holes. The holes 22 penetrate the upper ends of the fixed mounting frame 5 and the mobile mounting frame 6 and the two mounting grooves 21 respectively, and the ...

Embodiment 2

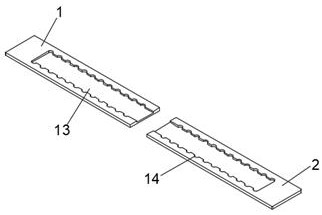

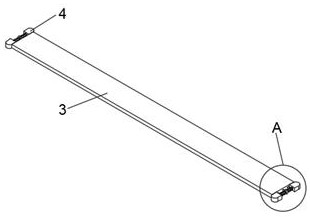

[0034] Such as figure 1 , 2 , 3, and 4, the lower end of the fixed mounting frame 5 is provided with a No. 1 base plate 1, the lower end of the mobile mounting frame 6 is provided with a No. 2 base plate 2, and the upper end of the No. 1 base plate 1 is fixed with a No. 1 guide rail by screws. 11. The upper end of the No. 2 bottom plate 2 is fixed with a No. 2 guide rail 12, and the inner ends of the No. 1 bottom plate 1 and the No. 2 bottom plate 2 are provided with a storage slot 13, and the inner walls of the two storage slots 13 are symmetrically opened. There are several arc-shaped fixing slots 14, and the arc-shaped fixing slots 14 are semicircular structures. An anti-off connecting plate 3 is installed in the No. 1 base plate 1 and No. 2 base plate 2, and the anti-off connecting plate 3 is installed on a In the two receiving grooves 13 that No. base plate 1 and No. two base plate 2 inner ends offer, the left and right ends of the anti-off connecting plate 3 are symmetr...

Embodiment 3

[0036] Such as image 3 , 4 , 6, four fixing devices 4 are installed symmetrically in pairs on the anti-off connecting plate 3, and the fixing devices 4 include a fixing block 18, a connecting slider 19 and a push spring 20, and the connecting slider 19 is arranged on the fixing block 18 On the end face of one side, the push spring 20 is arranged on the inner end of the fixed block 18, and the four connecting sliders 19 on the four fixing devices 4 are respectively slidably installed in the four connecting anti-off grooves provided on the anti-off connecting plate 3 15, the four fixed blocks 18 are located at the left and right ends of the anti-off connecting plate 3 respectively, and the four push springs 20 are respectively sleeved on the four spring guide posts 17, and the four fixed blocks 18 are all snapped into the arc In the fixed card slot 14, the fixing device 4 can facilitate the mutual fixing of the anti-off connecting plate 3, the No. 1 base plate 1 and the No. W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com