Multifunctional product implanter equipment

An implanting machine, multi-functional technology, applied in the field of implanting machines, can solve problems such as adjustment of the lower mold device, easy scrapping of products, and reduction of efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

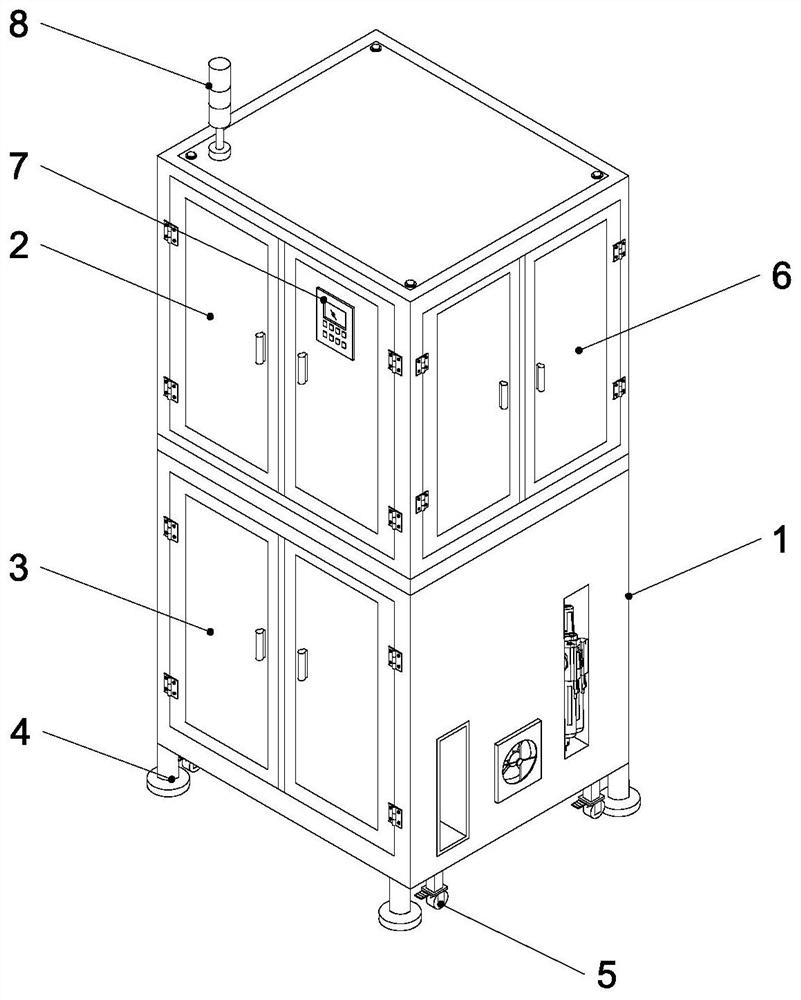

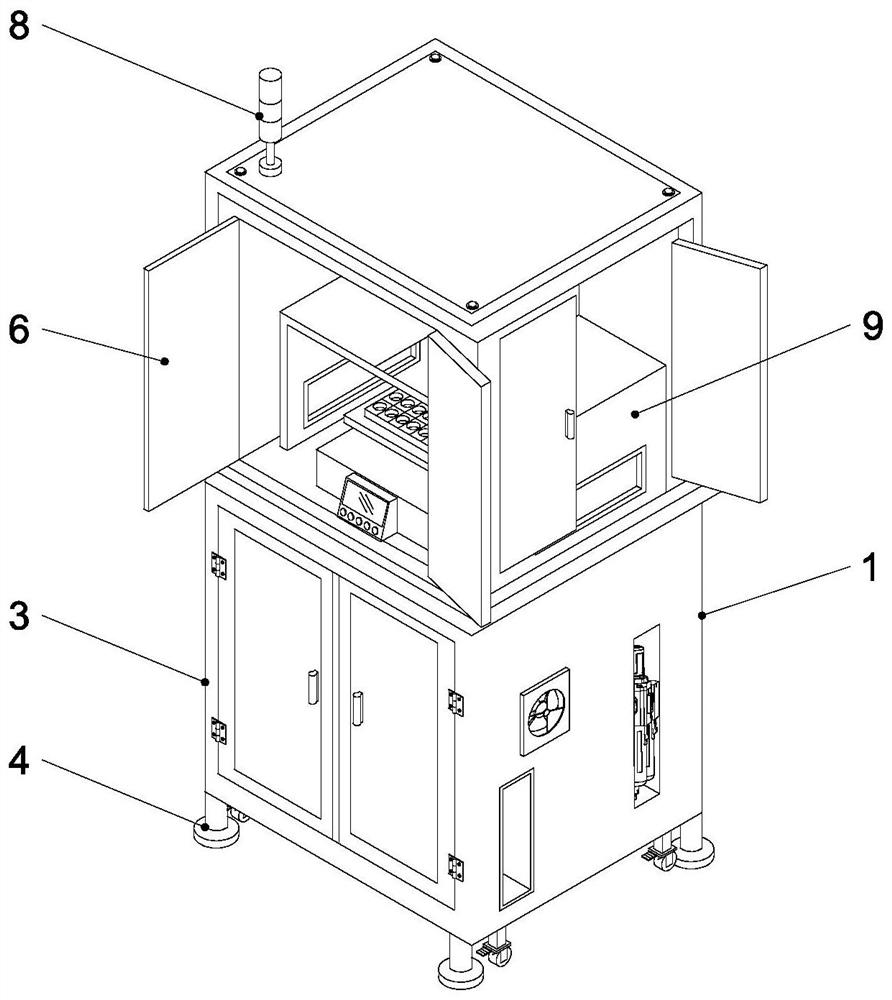

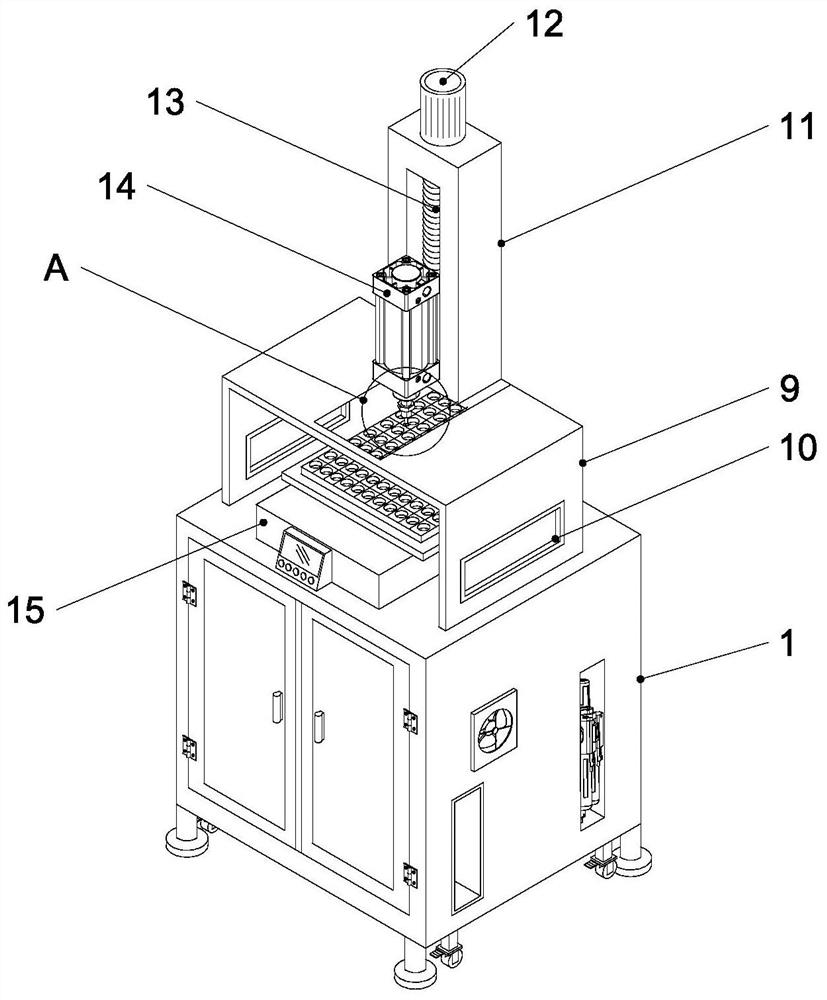

[0020] Example: such as Figure 1-5 As shown, a multifunctional product implanter device of the present invention includes a box body 1 and an implanter 14, and the inside of the box body 1 is respectively provided with an upper box body 2 and a lower box body 3 through a partition plate, and the lower box body The bottom of 3 is fixedly welded with a support seat 4, and the side close to the support seat 4 is provided with a roller 5, and the roller 5 has a wheel brake. The upper and lower ends of the front side of the box body 1 and one side of the box body 1 are connected by hinge rotation There is an opening and closing door 6, and the front side of the opening and closing door 6 is fixedly welded with a handle, the surface of the front opening and closing door 6 of the upper box body 2 is embedded with a control panel 7, and the top of the box body 1 is fixedly connected with an alarm light 8 And it is electrically connected with the control panel 7 through connecting wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com