Preparation method of shoe sole accessory with textures

A technology of texture and accessories, which is applied in the field of preparation of shoe sole accessories, can solve the problems such as the process of chemical etching and biting, and achieve the effect of efficient design and improved anti-slip performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The invention provides a method for preparing a textured sole fitting, comprising the following steps:

[0036] a) Establishing a plane grayscale figure comprising sole texture features;

[0037] b) map the plane gray-scale figure that step a) establishes to the surface of the 3D model, and export the 3D model that contains the sole texture feature to the SLA3D printer system through software, and carry out 3D printing wooden model;

[0038] c) Use the 3D printed wooden mold obtained in step b) to lay a soft mold, make a supporting plaster, and then overcast the mold, and finally use the mold to complete the production of the shoe sole accessories with texture.

[0039]The present invention firstly establishes a plane gray-scale figure containing sole texture features. In the present invention, the grayscale value of each pixel is preferably set in the plane grayscale figure; the range of the grayscale value is preferably 0-255; the magnitude of the value represents th...

Embodiment

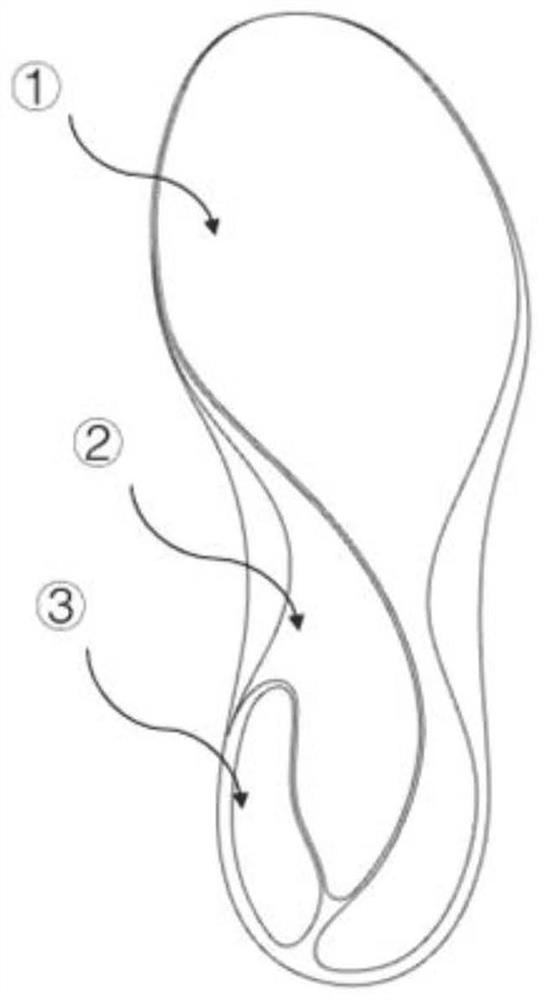

[0065] like figure 1 As shown, the contours of different areas of the bottom view plane figure of the sole are divided, and the contour boundary is the projection of the 3D model under this view.

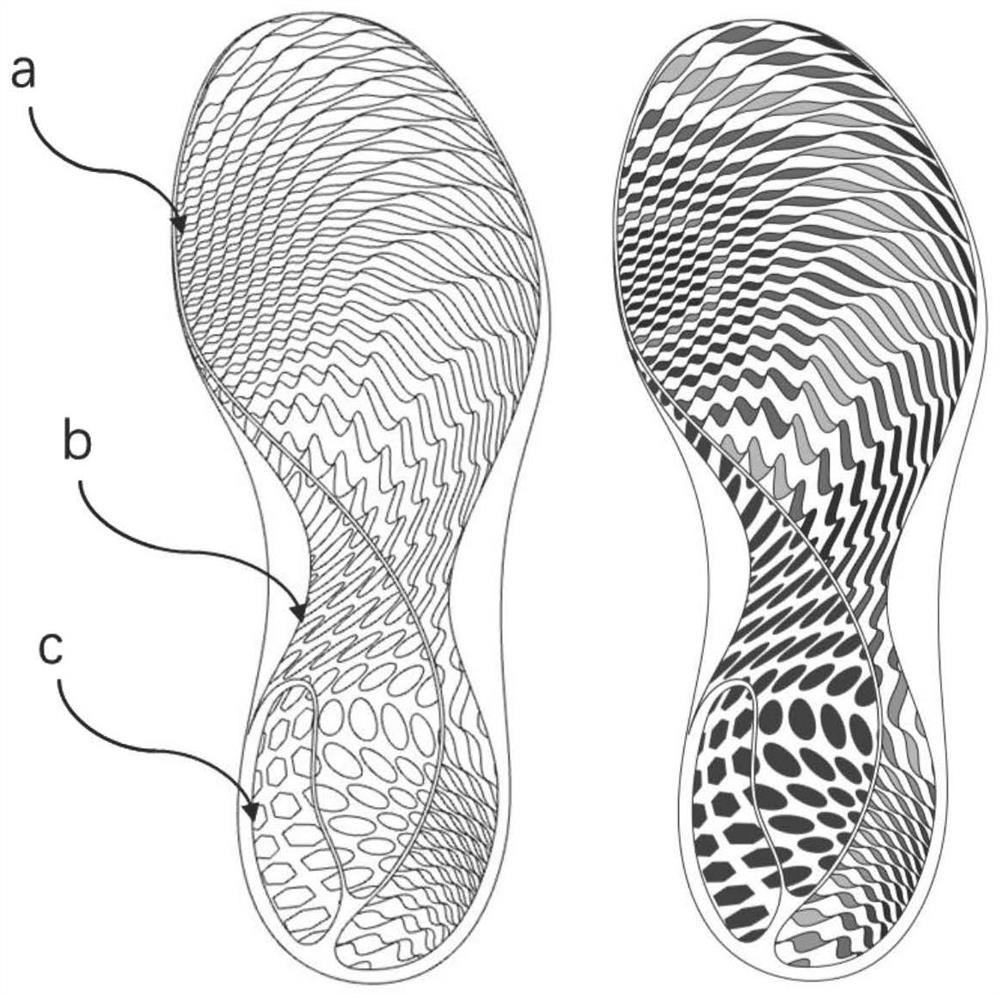

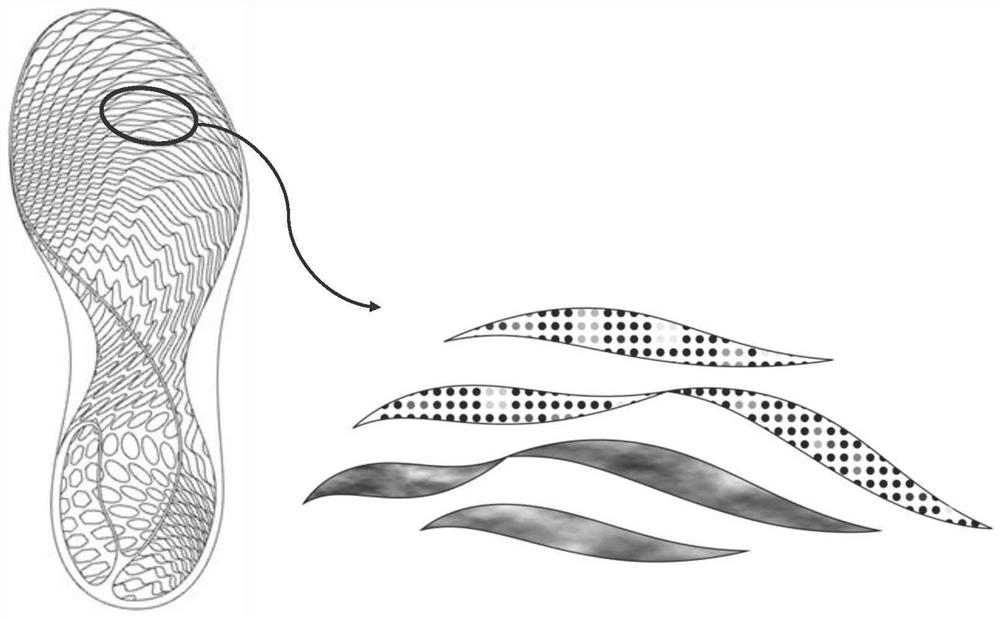

[0066] see figure 2 As shown, place different a, b, c in different areas, 3 different graphics with smaller sizes, and apply different gray values to these graphics; a single color block can be placed in each small graphics range, Represents a single grayscale value. It is also possible to place discrete graphics with smaller sizes or color blocks with continuously changing gray values, such as image 3 shown.

[0067] Furthermore, the gray value of these color blocks is actually determined by the three components of RGB. For the gray value, the change of the final gray value can be controlled by setting the RGB value in the software.

[0068] see further Figure 4 As shown, the mapping accurately projects each gray value of the planar image onto the surface of the 3D model,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com