Grouting sleeve structure and construction method

A technology of grouting sleeves and construction methods, which is applied to structural elements, building components, building structures, etc., and can solve problems such as complex construction process, inability to improve grouting efficiency, and reduce human and financial costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

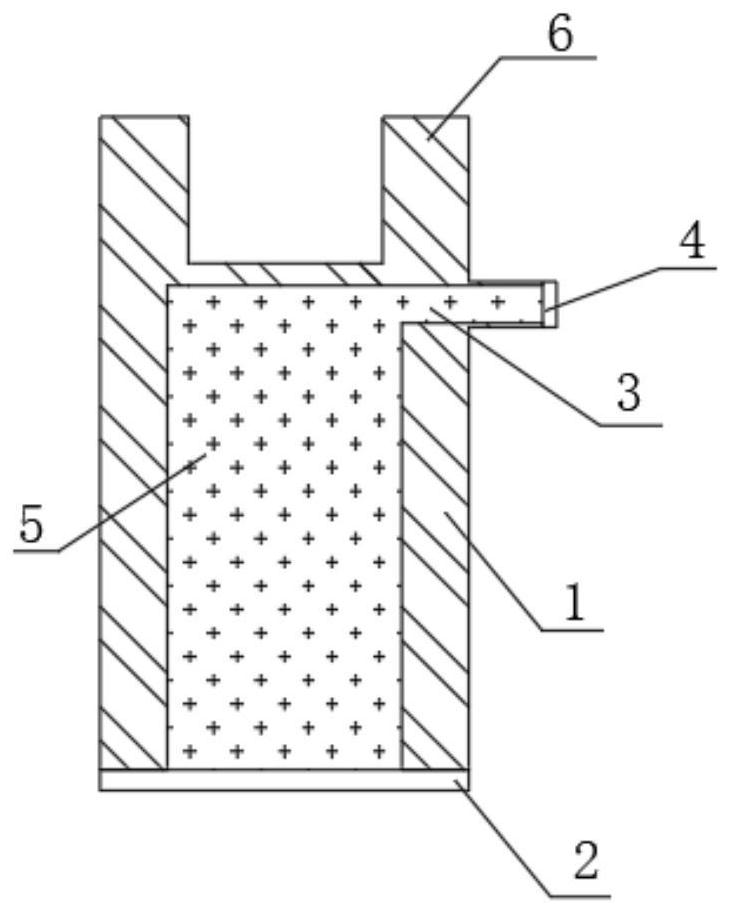

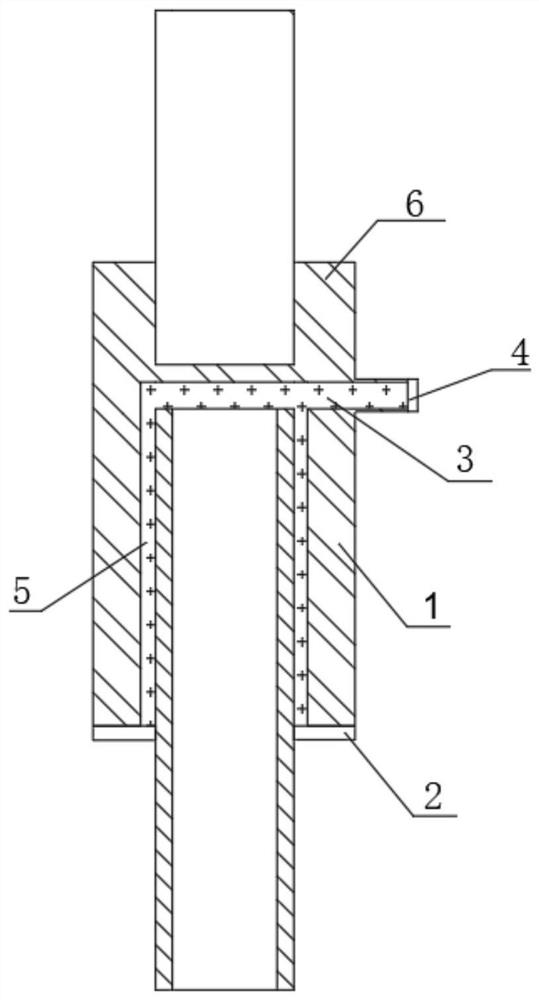

[0023] refer to figure 1 , a grouting sleeve structure in this embodiment, including a sleeve 1, a sleeve envelope 2 arranged at the bottom of the sleeve 1, a grout hole 3 arranged at the top of the wall of the sleeve 1, a grout hole 3 arranged at the The overflow port cover 4 at the overflow port, and the structural glue 5 arranged in the sleeve 1 .

[0024] A kind of grouting sleeve structure of this embodiment, the structural adhesive 5 is packaged in the sleeve 1, and during construction, the steel bar to be connected is inserted into the sleeve 1 from the sleeve envelope 2, and the structural adhesive 5 in the sleeve 1 and After the connected steel bars are in contact, a reaction can occur to form a solidified body, thereby forming a force-transmitting structure and completing the connection between components.

[0025] The grouting sleeve structure of this embodiment, compared with the traditional grouting sleeve construction process, eliminates the grouting operation, ...

Embodiment 2

[0030] refer to figure 1 , figure 2 , the present embodiment provides a construction method of the grouting sleeve structure described in Embodiment 1, and the technical scheme is as follows:

[0031] A construction method for a grouting sleeve structure, comprising the steps of:

[0032] In the first step, the structural glue 5 is filled in the sleeve 1;

[0033] In the second step, the grouting sleeve structure is in place;

[0034] The third step is to uncover the cover 4 of the overflow port, insert the steel bar to be connected into the sleeve 1 from the sleeve cover 2, the structural glue 5 reacts with the steel bar to be connected, and forms a solid to wrap the steel bar to be connected, and completes the installation of the steel bar to be connected connect.

[0035] In the construction method of a grouting sleeve structure in this embodiment, the structural glue 5 is encapsulated in the sleeve 1. During construction, the steel bar to be connected is inserted into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com