Comprehensive sealing structure of screw pump

A sealing structure and screw pump technology, applied in pumps, pump components, rotary piston pumps, etc., can solve the problems that high-pressure gas cannot play a role, and achieve the effects of compact structure, improved service life, and reasonable use of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following are specific embodiments of the present invention and the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

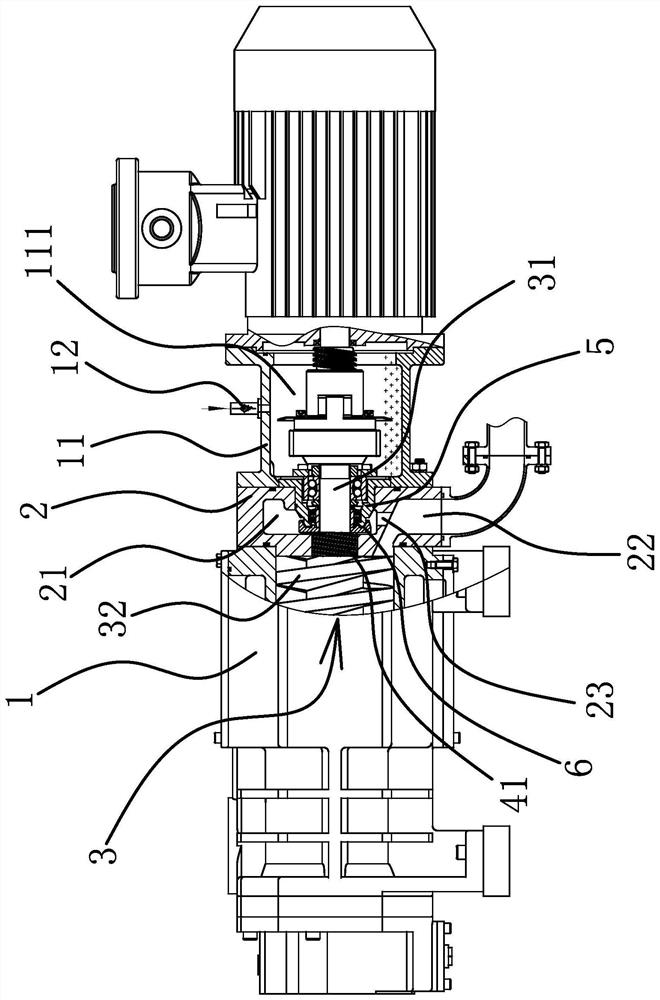

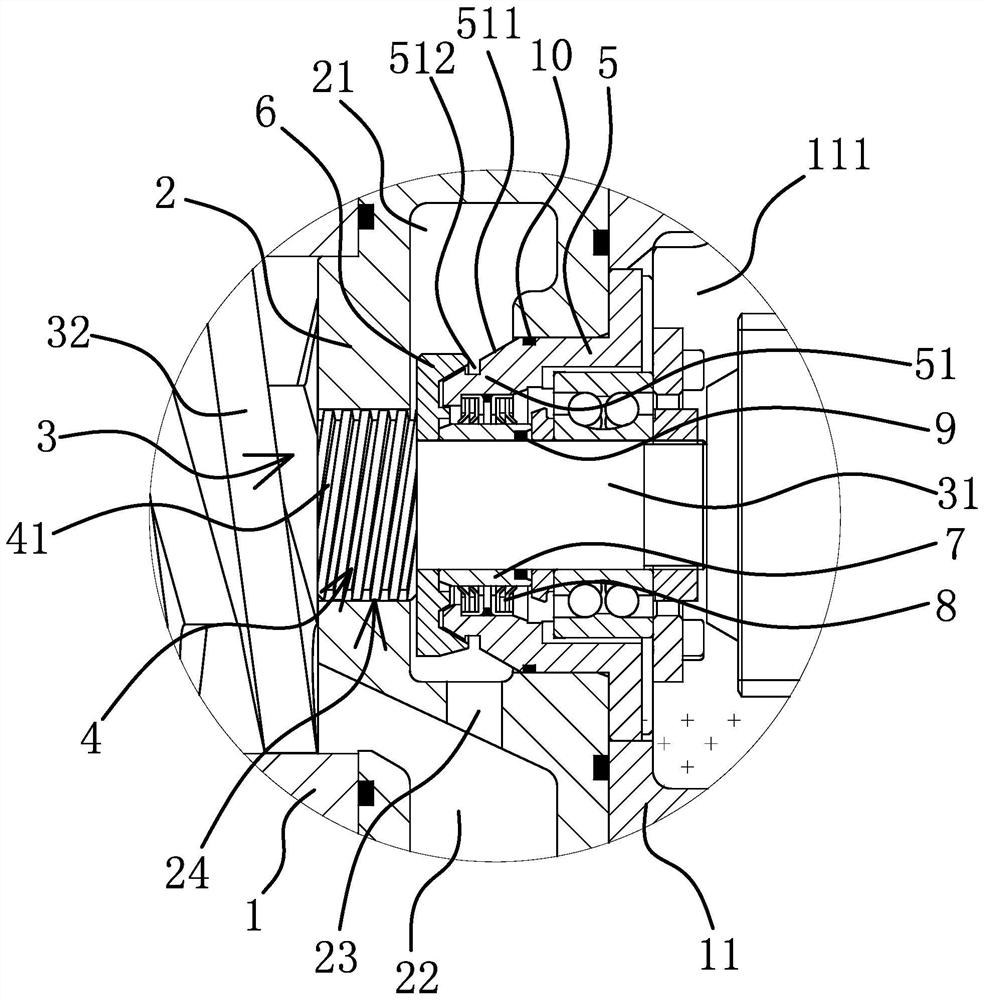

[0025] like figure 1 , figure 2 As shown, the screw pump includes a pump body 1, a sealing cover 2, a gear cover 11 and a sealing structure. The sealing structure includes the balance hole 23 , the sealing channel 41 , the sealing portion 51 , the oil guiding groove 512 and the centrifugal disc 6 .

[0026] The sealing cover 2 is fixedly arranged between the pump body 1 and the gear cover 11. The pump body 1 is provided with a screw 3 and the rotating shaft 31 of the screw 3 extends into the balance chamber 21 inside the sealing cover 2. The gear cover 11 has lubricating oil. In the cavity 111 , the gear cover 11 is provided with a pressurizing pipe 12 , one end of the pressurizing pipe 12 is used to communicate with the compressed nitrogen g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com