High-speed ball bearing retainer and high-speed ball bearing of using same

A technology of bearing cages and cages, which is applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of easily burned bearings and cage valgus, and achieve the effect of high overall rigidity and damage prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

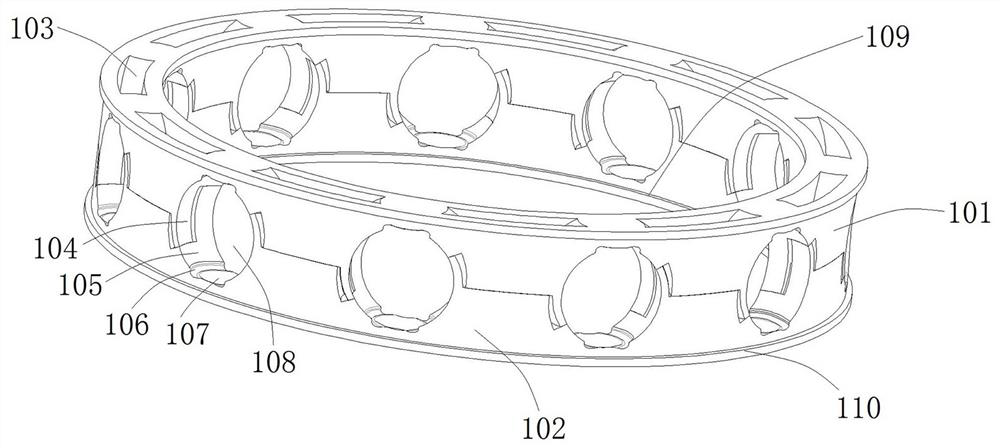

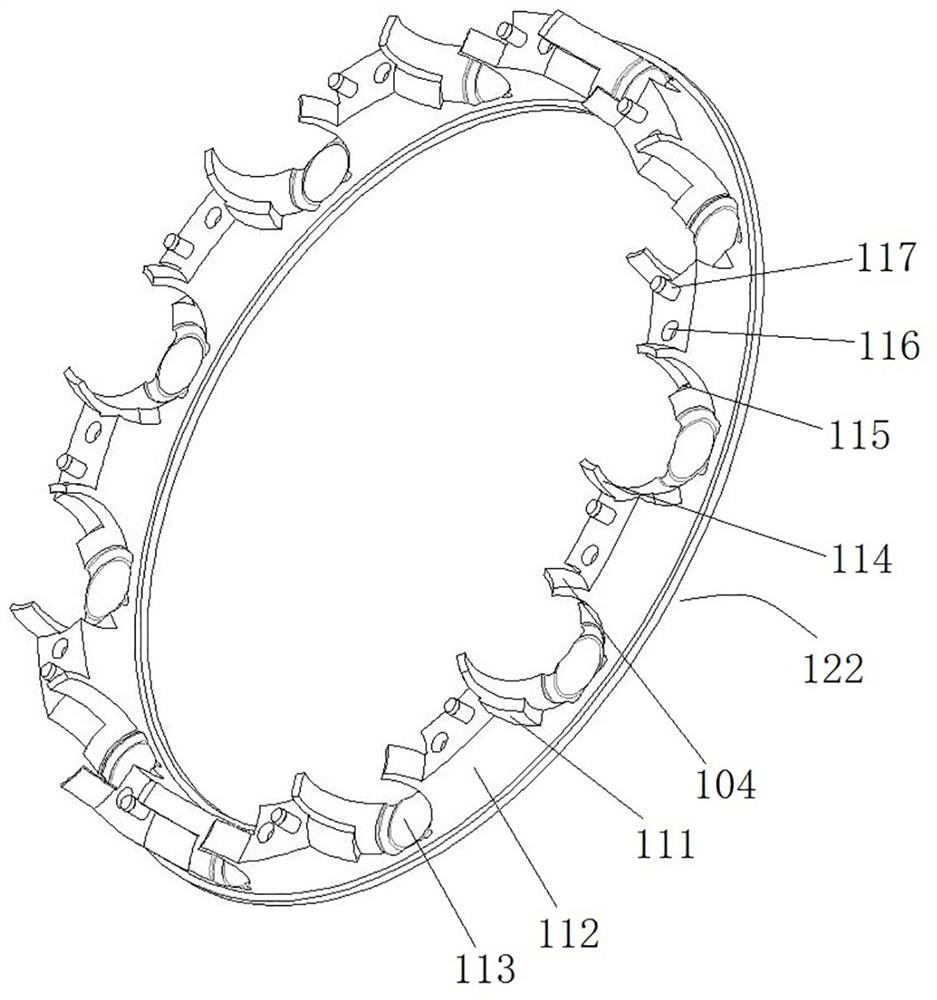

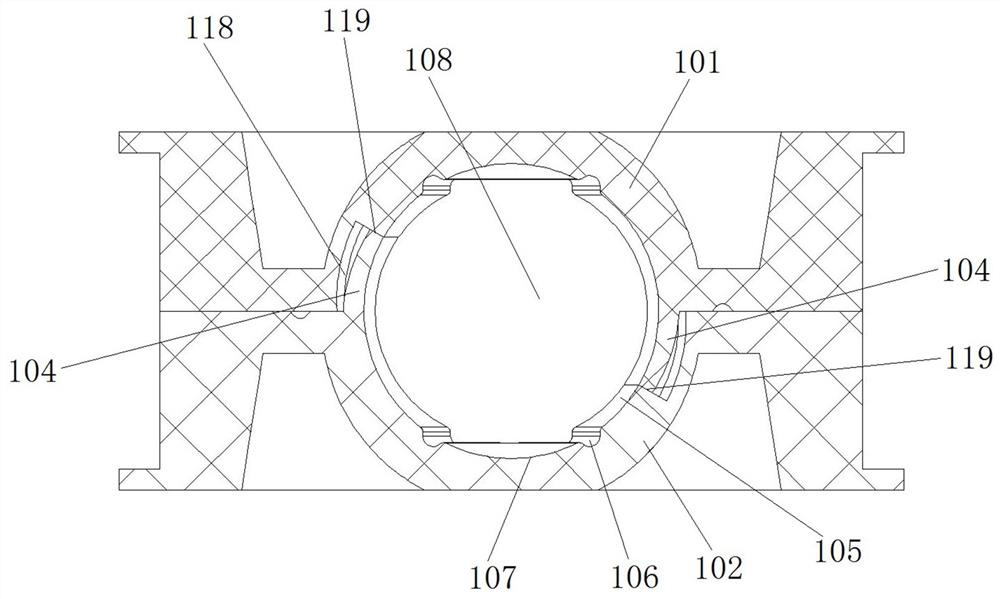

[0066] Such as Figure 1 to Figure 5 As shown, the high-speed ball bearing cage (hereinafter referred to as the cage) of the present invention is integrally injection-molded, and is specifically composed of two identical cages that are injection-molded by thermoplastics, especially polyamide modified plastics, through connection. As a whole, it eliminates the tendency of the lock claws to turn out and deform in the prior art, improves the overall rigidity of the cage, and ensures that under high-speed rotation, the cage will not cause the lock claws to turn up and contact the outer ring of the bearing due to the large centrifugal force , causing a lot of heat to burn the bearings.

[0067] Such as figure 1 As shown, the cage is formed by connecting two separate cages, and the structures of the two cages are the same. For description, in this embodiment, the two cages are defined as the first cage split 101 and the second cage respectively. The cage split 102 is described by ...

Embodiment 1

[0080] In Embodiment 1, a pocket oil groove is arranged in the pocket. In this embodiment, the position and shape of the pocket oil groove can be changed according to the actual situation, and the pocket oil groove can also be eliminated.

specific Embodiment 3

[0082] In Embodiment 1, there are protruding rings on the inner and outer sides of the annular body, and oil storage grooves are formed on the inner and outer sides. In this embodiment, the oil reservoir may be formed only on the inner side or only on the outer side. Or the oil storage tank can be canceled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com