Hall sensor chip temperature compensation method for automobile

A Hall sensor and temperature compensation technology, applied in the direction of instruments, voltage/current isolation, measuring devices, etc., can solve the problems of large amount of calculation, heavy burden, and low efficiency of temperature compensation processing of single-chip computers, and achieve good adaptability and processing fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

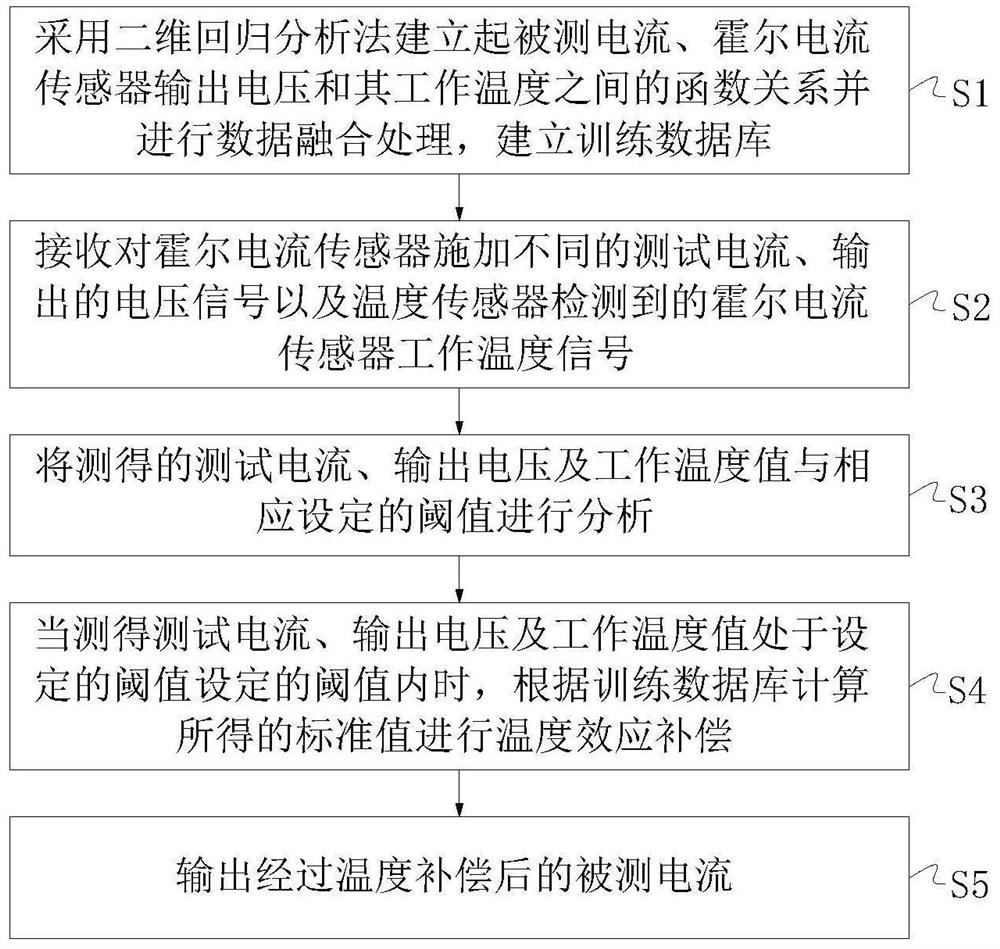

[0022] see figure 1 , the present invention provides the following technical solutions: a method for compensating the temperature of a Hall sensor chip for an automobile, comprising the following steps:

[0023] Step S1, using a two-dimensional regression analysis method to establish the functional relationship between the measured current, the output voltage of the Hall current sensor and its operating temperature, and perform data fusion processing to establish a training database;

[0024] Step S2, receiving different test currents applied to the Hall current sensor, the output voltage signal and the operating temperature signal of the Hall current sensor detected by the temperature sensor;

[0025] Step S3, analyzing the measured test current, output voltage and operating temperature values and corresponding set threshold values;

[0026] Step S4, when the measured test current, output voltage and operating temperature are within the set threshold, perform temperature e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com