Equipment anomaly detection method using Gaussian noise

A Gaussian noise and detection method technology, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve problems such as difficulty in supervised learning and difficulty in providing multi-failure mode fault early warning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings. This embodiment is only used to explain the present invention, and does not constitute a limitation to the protection scope of the present invention.

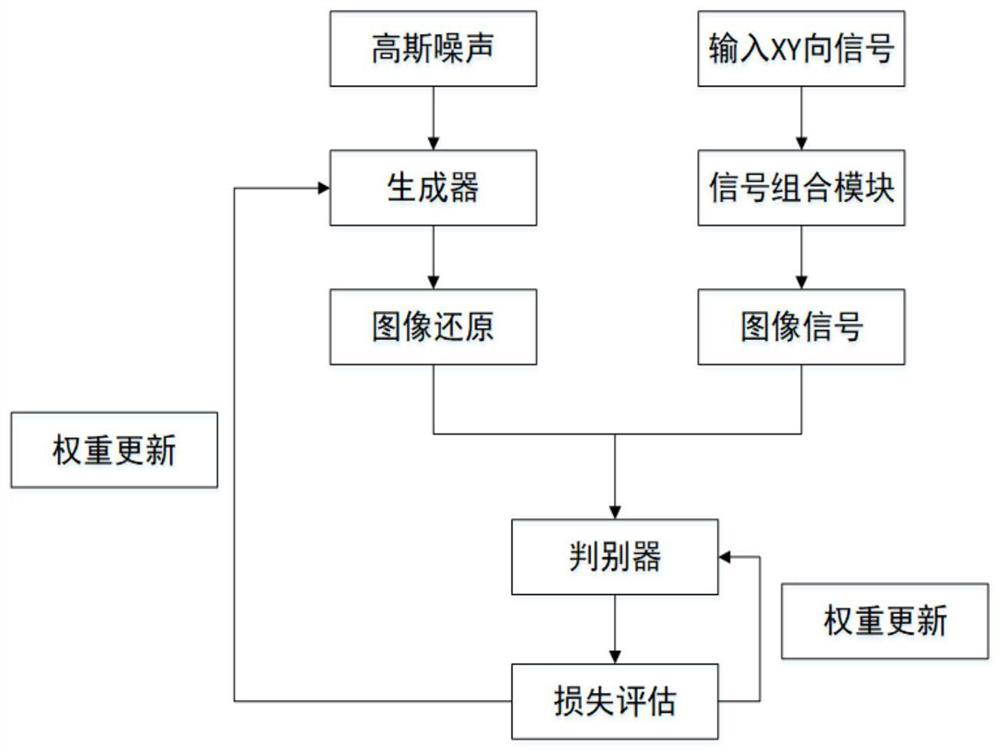

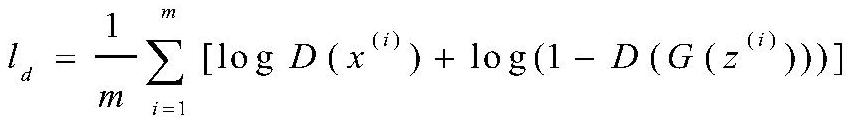

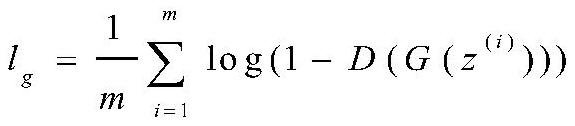

[0035] Such as figure 1 As shown, training a generator capable of generating real normal vibration signals includes the following steps:

[0036] Step 1: Define and initialize the Gaussian noise distribution p g :

[0037] By restricting the noise to a certain distribution p g ~N(0,1), that is, as the latent vector mapping space of the normal vibration signal image, this space is the feature representation of the normal vibration signal image. Among them, the latent vector mapping space is used to represent the features of the normal vibration signal, that is, the feature space. Since the feature is a vector representation in the network, it is also called ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com