Self-extinguishing cable

A technology for fire extinguishing cables and air chambers, which is applied in the direction of insulated cables, cables, circuits, etc., and can solve the problems of not being able to effectively and reliably avoid burning of wires and cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

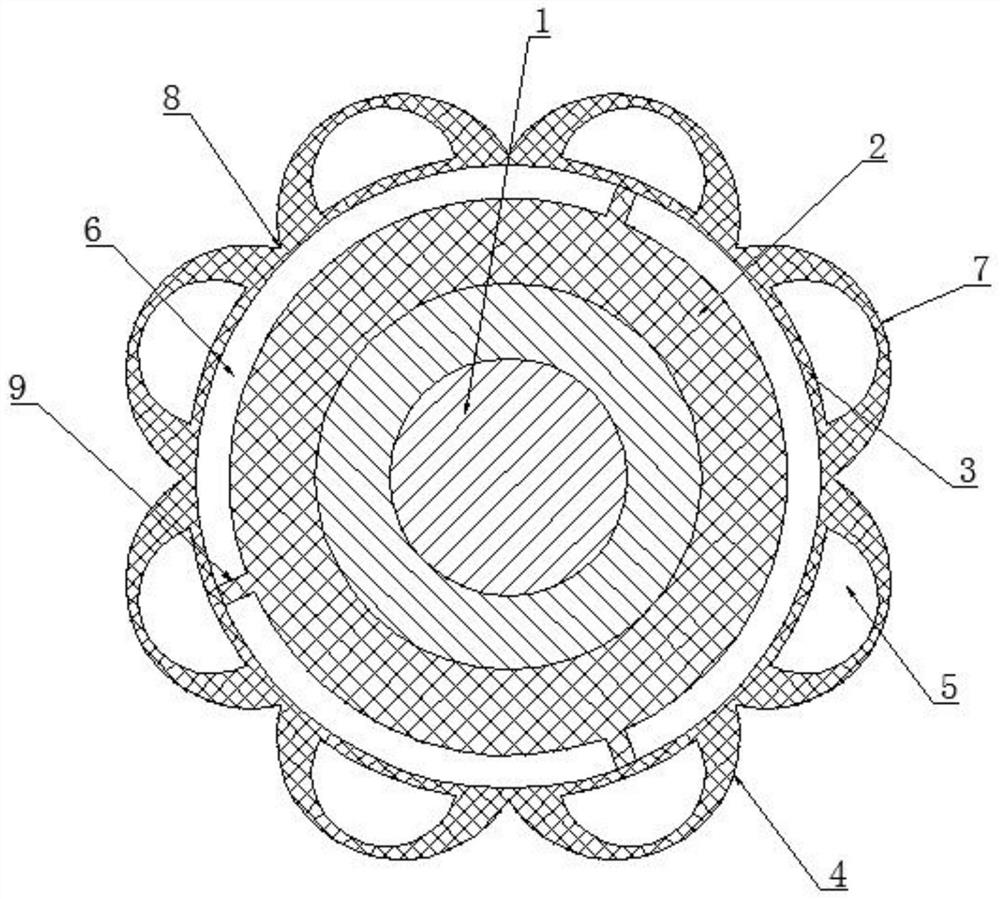

[0019] Embodiment 1, basically as attached figure 1 Shown: a self-fire-extinguishing cable, including a conductor 1, the outer side of the conductor 1 is covered with an insulating layer, the outer side of the insulating layer is covered with a sheath layer, and eight airbag strips 4 are evenly distributed in a ring on the outer wall of the sheath layer, and the adjacent airbags The strips 4 offset each other, and the airbag strip 4 is integrally formed with the sheath layer. The cross-sectional profile of the airbag strip 4 is semi-elliptical, and the airbag strip 4 is provided with a first air chamber 5. The cross-sectional contour of the first air chamber 5 is semicircular. The chamber 5 is filled with an inert gas, preferably carbon dioxide. The sheath layer is provided with a second air cavity 6 surrounding the conductor 1, the second air cavity 6 separates the sheath layer into an inner sheath layer 2 and an outer sheath layer 3, and the second air cavity 6 is also fill...

Embodiment 2

[0022] Embodiment 2. In this embodiment, two gas nozzles are hot-melt connected on the sheath layer, one gas nozzle penetrates into the first air chamber, and the other gas nozzle penetrates into the second air chamber. In this embodiment, by setting the gas nozzle on the sheath layer, the self-fire-extinguishing cable can be injected with inert gas through the gas nozzle when it has a stable structure after the sheath layer is produced, which is more convenient for the first air cavity And the control and maintenance of the gas pressure in the second air chamber is stable, the inert gas injection operation is more convenient, and it is more conducive to reducing the production cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com