Annular transformer mounting structure

A technology of a toroidal transformer and an installation structure, applied in the field of transformers, can solve the problems of poor heat dissipation effect, reduced service life of toroidal transformers, and high safety hazards, and achieve the effects of improving service life, improving heat dissipation effect, and reducing safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

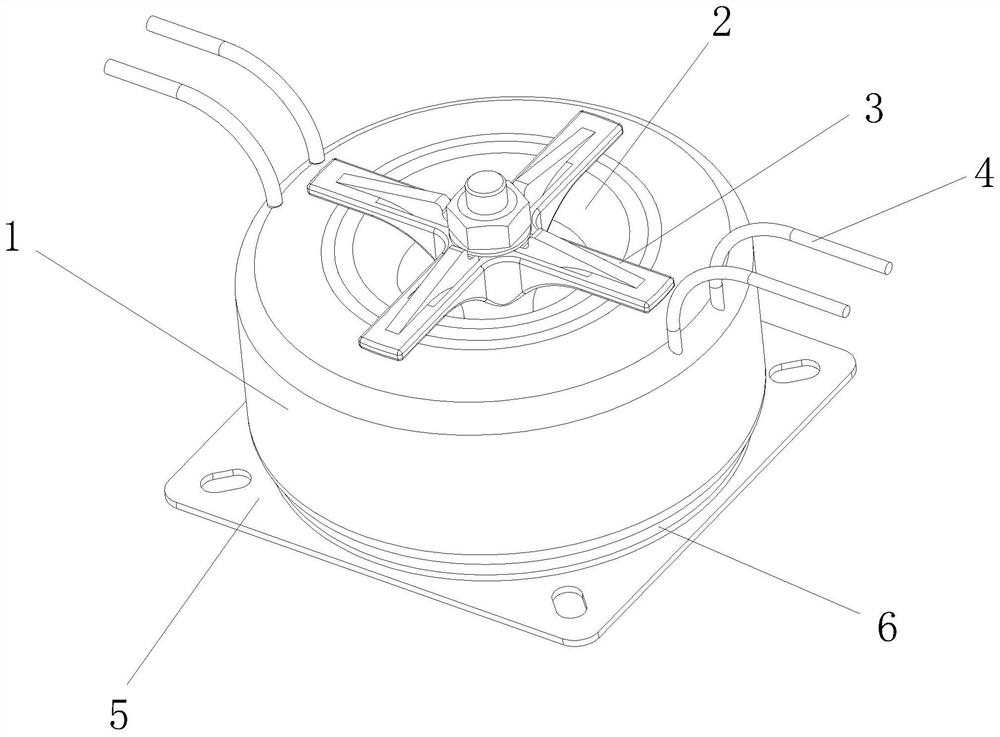

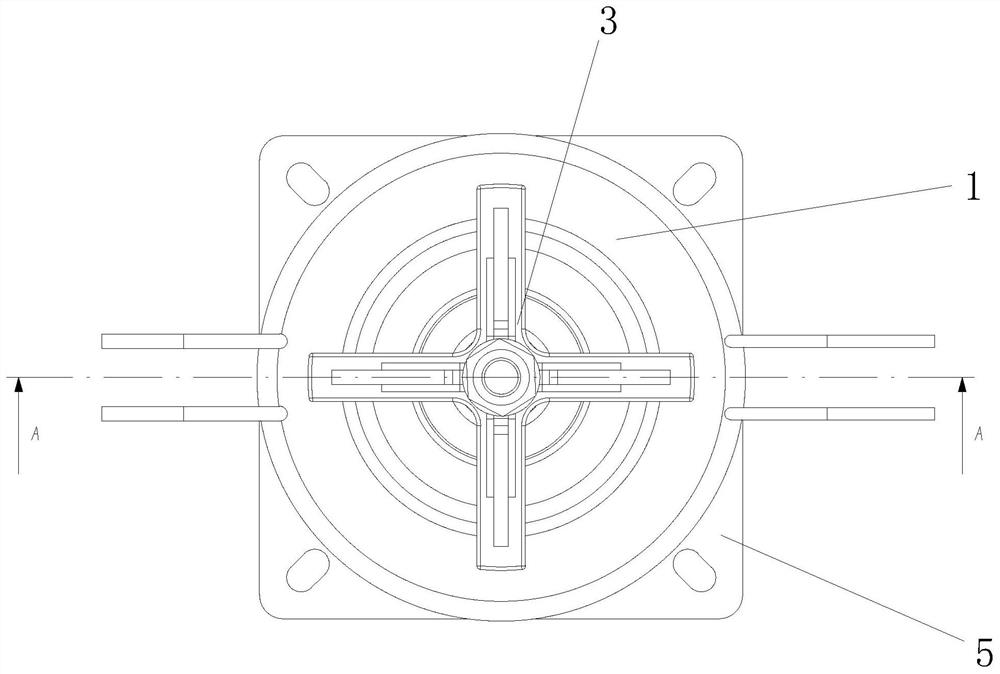

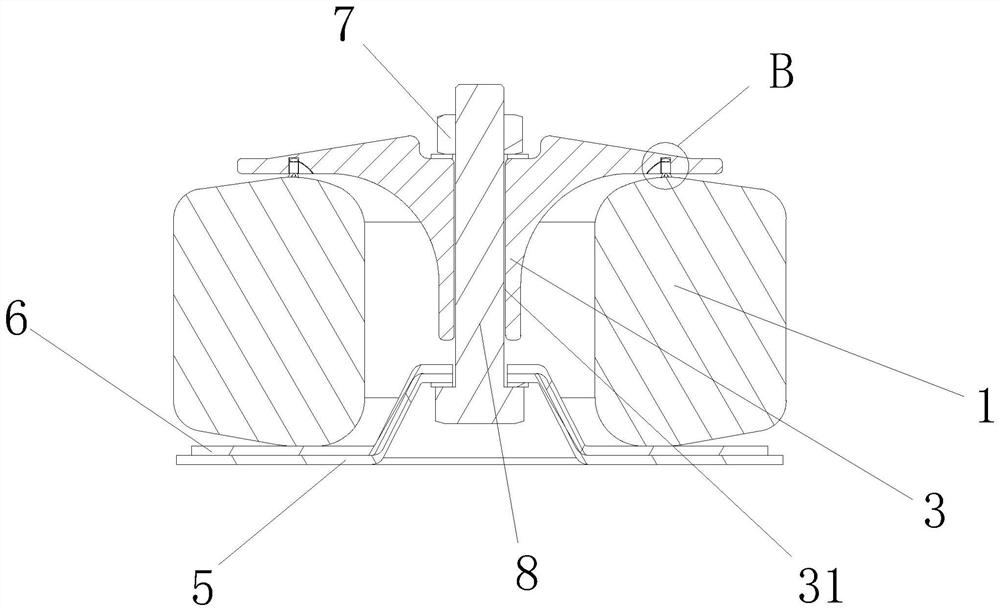

[0023] Such as figure 1 , 2 , 3, 4, a toroidal transformer installation structure, including a toroidal transformer body 1 with an inner hole 2, the toroidal transformer body 1 is provided with a lead wire 4, and also includes a fastening pressure piece 3 and a matching with the chassis bottom plate 5 The lower gasket 6, the lower gasket 6 is made of rubber material, so that the lower gasket 6 has a certain degree of elasticity, which can absorb the vibration energy when the product is running, so as to improve the stability of the toroidal transformer after installation, and fasten the pressing parts 3. The lower gasket 6 and the chassis bottom plate 5 are connected through a connecting component. The fastening pressing piece 3 includes a fastening body 32. The end of the fastening body 32 away from the lower gasket 6 is provided with a ring for pressing on the toroidal transformer body 1. When installing, the lower gasket 6 is located on the lower surface of the toroidal tr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap