Crushing and screening all-in-one machine for fertilizer production line

A technology of production line and integrated machine, which is applied in the fields of filtration, solid separation, chemical instruments and methods, etc. It can solve problems such as screen clogging, affecting the uniformity of finished products, clogging, etc., and achieves the effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

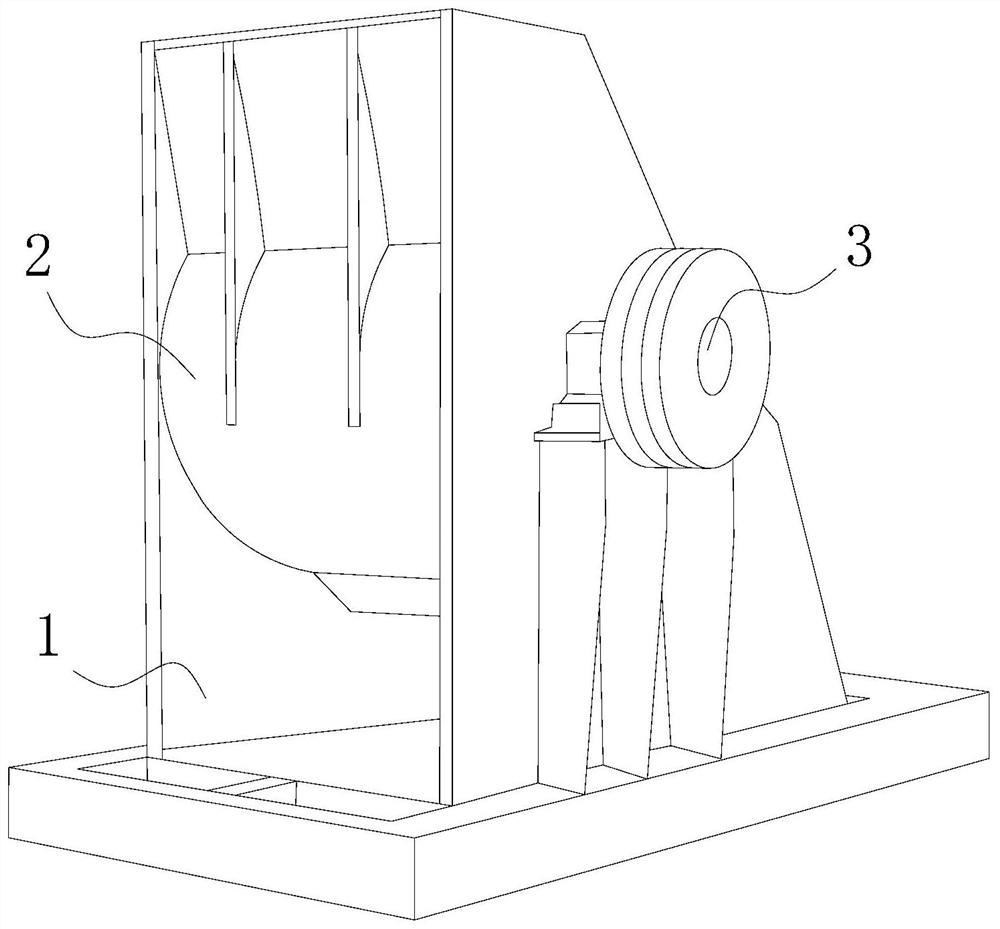

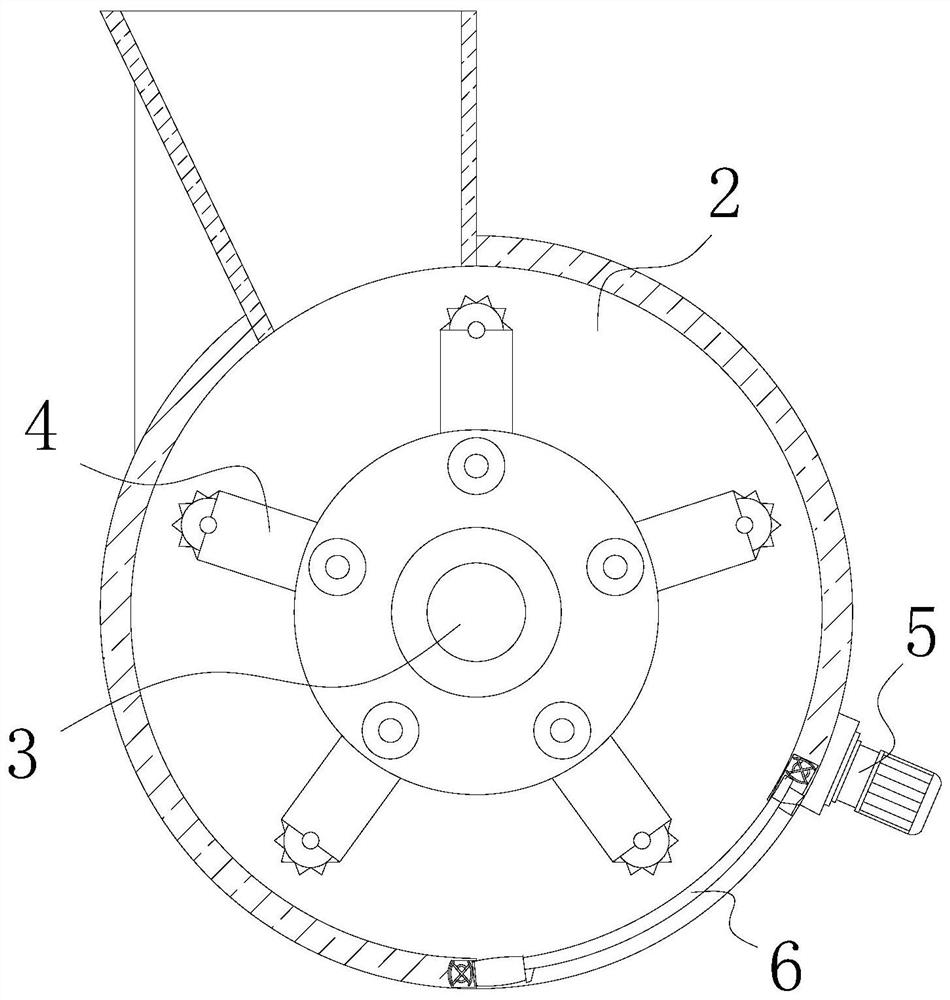

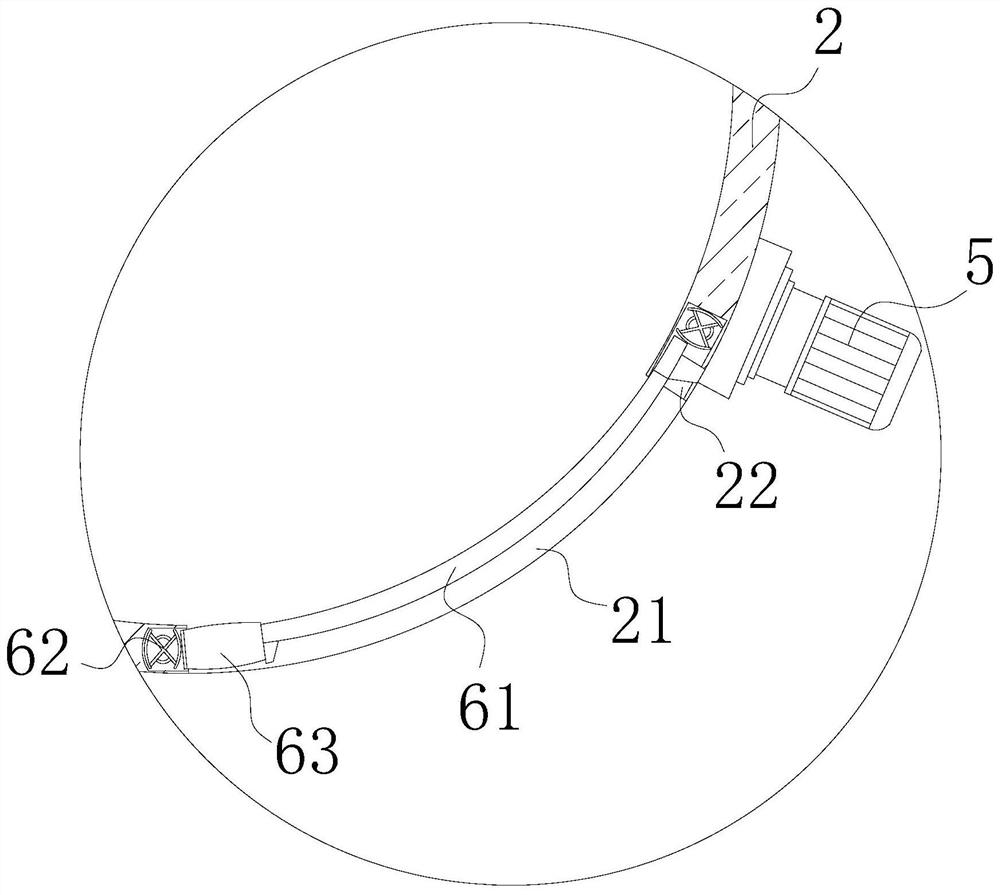

[0030] Such as Figure 1-Figure 3 As shown, the present invention provides a crushing and screening integrated machine for a fertilizer production line, its structure includes: a body 1, a crushing bin 2, a drive shaft 3, a crushing knife 4, a motor 5, a sieving device 6, and the crushing bin 2 It is in the shape of a cylinder and is arranged horizontally on the body 1. The transmission shaft 3 is arranged in the crushing bin 2 along the axial direction of the crushing bin 2. The crushing knife 4 is arranged on the transmission shaft 3. The bottom end of the body 1 is set There is a discharge opening 21 and a limiting groove 22, the limiting groove 22 is arranged at the top and bottom of the discharging opening 21, and the sieving device 6 is arranged on the discharging opening 21 and is locked with the limiting groove 22 Together, the motor 5 is fixed on the outside of the crushing bin 2 and connected with the sieving device 6, the sieving device 6 is composed of a screen 61,...

Embodiment 2

[0039] Such as Figure 1-Figure 3 As shown, the present invention provides a crushing and screening integrated machine for a fertilizer production line, its structure includes: a body 1, a crushing bin 2, a drive shaft 3, a crushing knife 4, a motor 5, a sieving device 6, and the crushing bin 2 It is in the shape of a cylinder and is arranged horizontally on the body 1. The transmission shaft 3 is arranged in the crushing bin 2 along the axial direction of the crushing bin 2. The crushing knife 4 is arranged on the transmission shaft 3. The bottom end of the body 1 is set There is a discharge opening 21 and a limiting groove 22, the limiting groove 22 is arranged at the top and bottom of the discharging opening 21, and the sieving device 6 is arranged on the discharging opening 21 and is locked with the limiting groove 22 Together, the motor 5 is fixed on the outside of the crushing bin 2 and connected with the sieving device 6, the sieving device 6 is composed of a screen 61,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com