Spinning forming method and spinning device for W-shaped metal sealing ring

A technology of spinning forming and sealing rings, which is applied in the field of metal ring manufacturing, can solve problems such as difficult positioning of workpieces, and achieve the effects of simple operation, convenient disassembly, and full consideration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

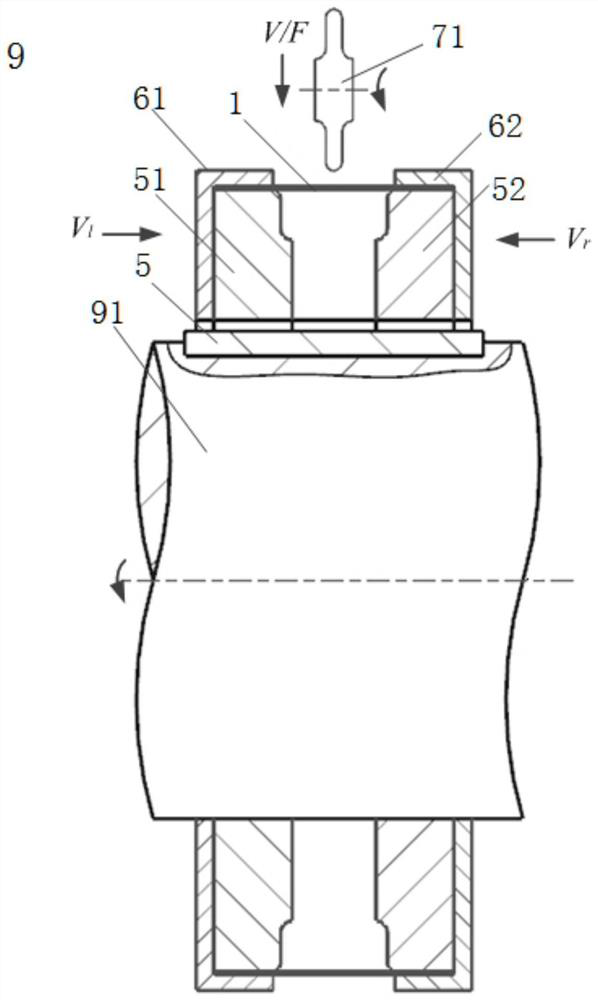

[0065]Such asfigure 1 ,2, 8, 9, 10, the present invention provides a rotary press forming method of a W-type metal seal, including the following steps:

[0066]S100. According to the axial cross section of the W-type metal seal, the ring embryoid 1 height of the W-type metal seal, prepared to prepare a height of annular embryo 1;

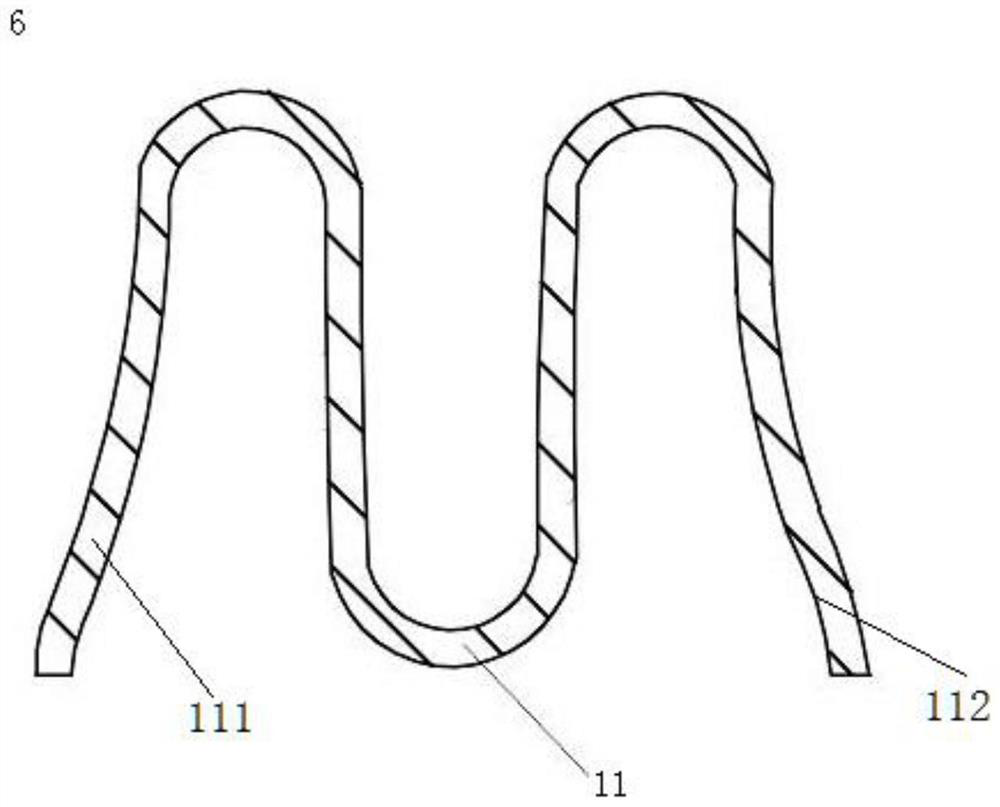

[0067]S200. The radial center of the ring embryo 1 prepared along step S100 is rotated from the annular waist trench portion 11, and the waist trench portion 11 is depressed in the direction of the annular embryo 1 axis;

[0068]S300. The circular embryo 1 is located on the portion of the waist trench portion 11 for rotary press processing, forming a W-type metal seal strike;

[0069]Among them, the waist trench portion 11 is embedded in the cavity of the second core 2 in the circular core groove portion 11 in the circular embryo 1, and the lumbar trench portion 11 is filled. The support ring 3 such that the support ring 3 is clamped to the second mold core 2 to clam...

Embodiment 2

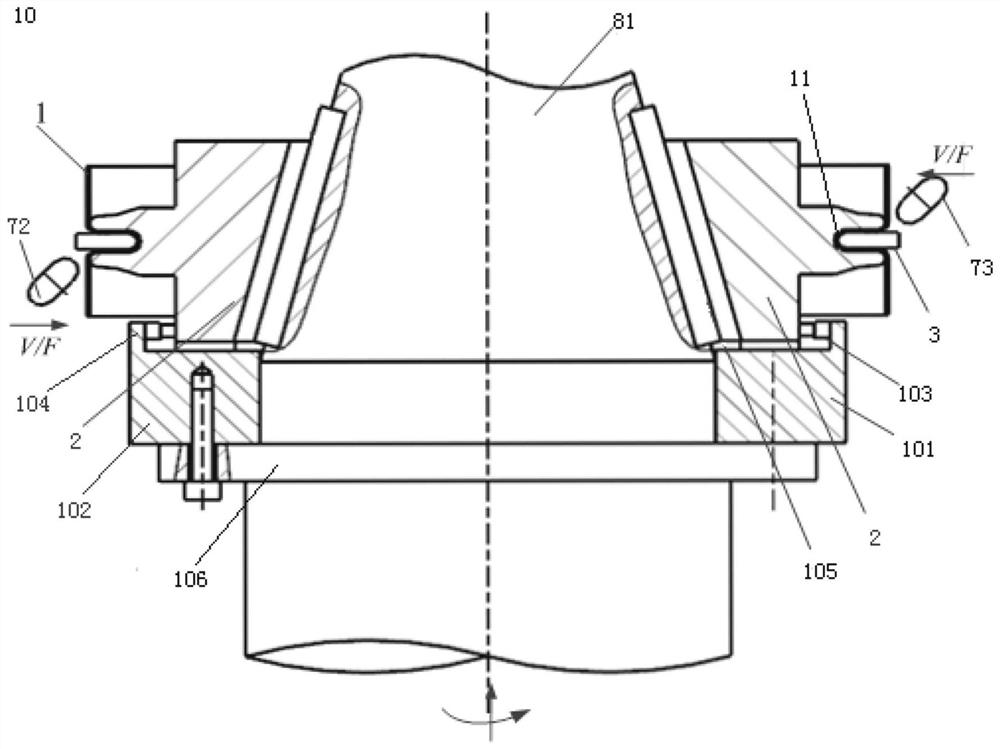

[0107]Such asfigure 1 ,2As shown, the present invention also requires a rotary pressing device for a W-type metal seal sealing, including the waist trench rotation device 9 and two end surface rotation devices for processing the waist groove portion 11 in the annular embryo 1. 10;

[0108]Two-end rotation device 10 includes

[0109]The second rotating shaft 81, the second rotating shaft 81 includes a conical cone;

[0110]The second core 2, the second mold core 2 consists of at least two fed-flap molds, each drive connection with the conical portion of the second rotating shaft 81, respectively; the fed-flap core includes and the waist groove The shape of the groove portion 11 is fitted, and the first side surface of the first bending portion 111 of the W-type metal sealing the halves of the W-shaped metal is adapted to the second curved portion 112 of the W-type metal sealing stroke. The second side of the shape is fitted;

[0111]The second rotary wheel 72, the second rotary wheel 72 always c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com