Spinning forming method and spinning device of w-shaped metal sealing ring

A technology of spinning forming and sealing rings, which is applied in the field of metal ring manufacturing, can solve problems such as difficult positioning of workpieces, and achieve the effects of simple operation, concise and clear calculation process, and sufficient consideration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

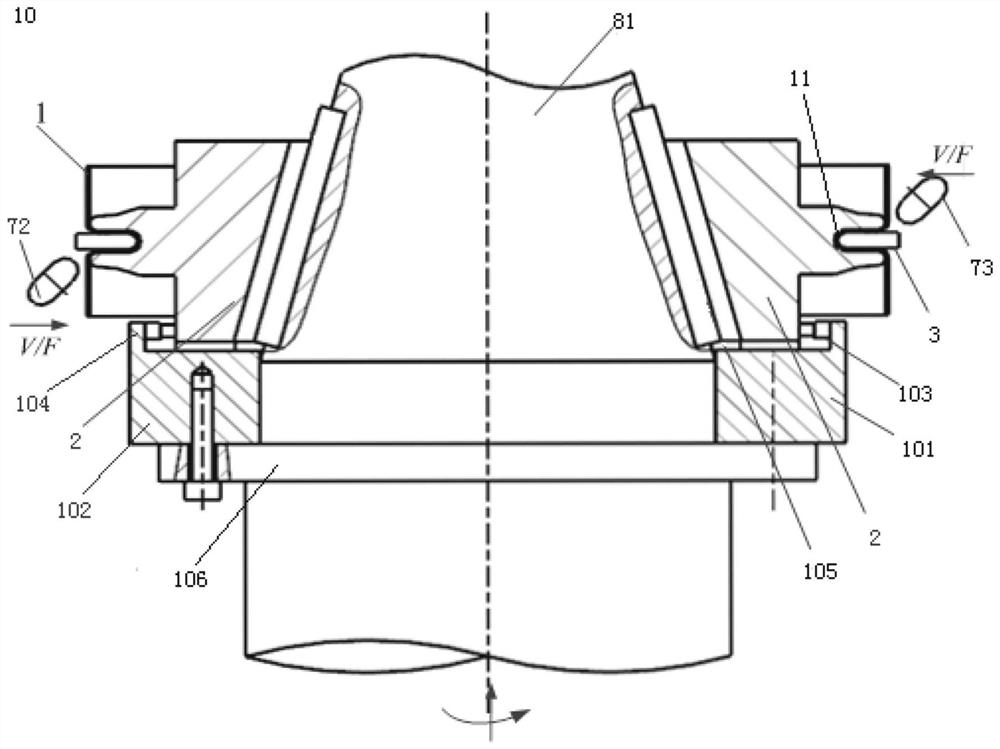

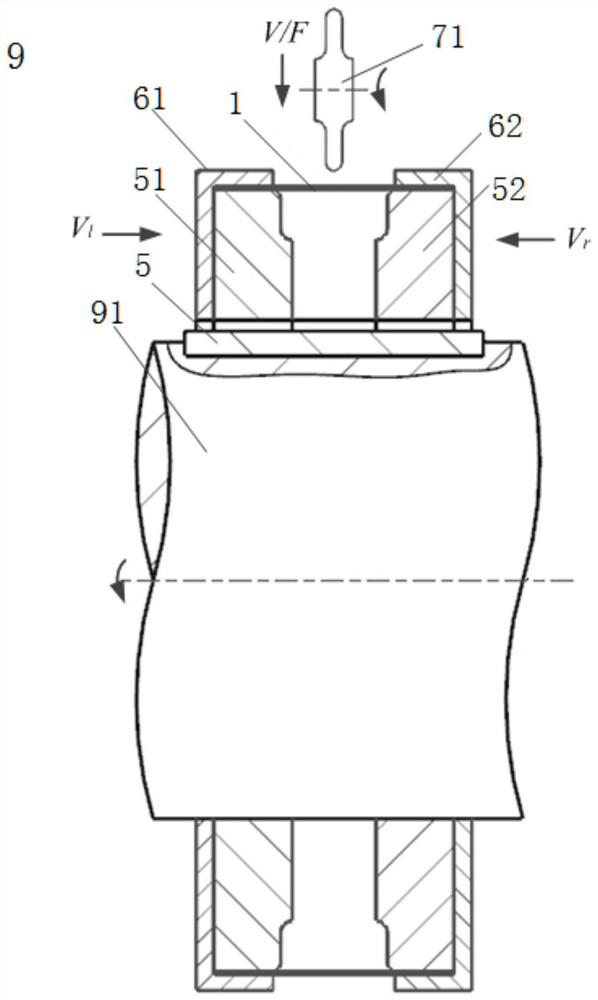

[0065] like figure 1 , 2 , 8, 9, and 10, the invention provides a spinning forming method of a W-shaped metal sealing ring, comprising the steps of:

[0066] S100. According to the axial section of the W-shaped metal sealing ring, calculate the height of the annular blank 1 of the W-shaped metal sealing ring, and prepare the annular blank 1 with a height;

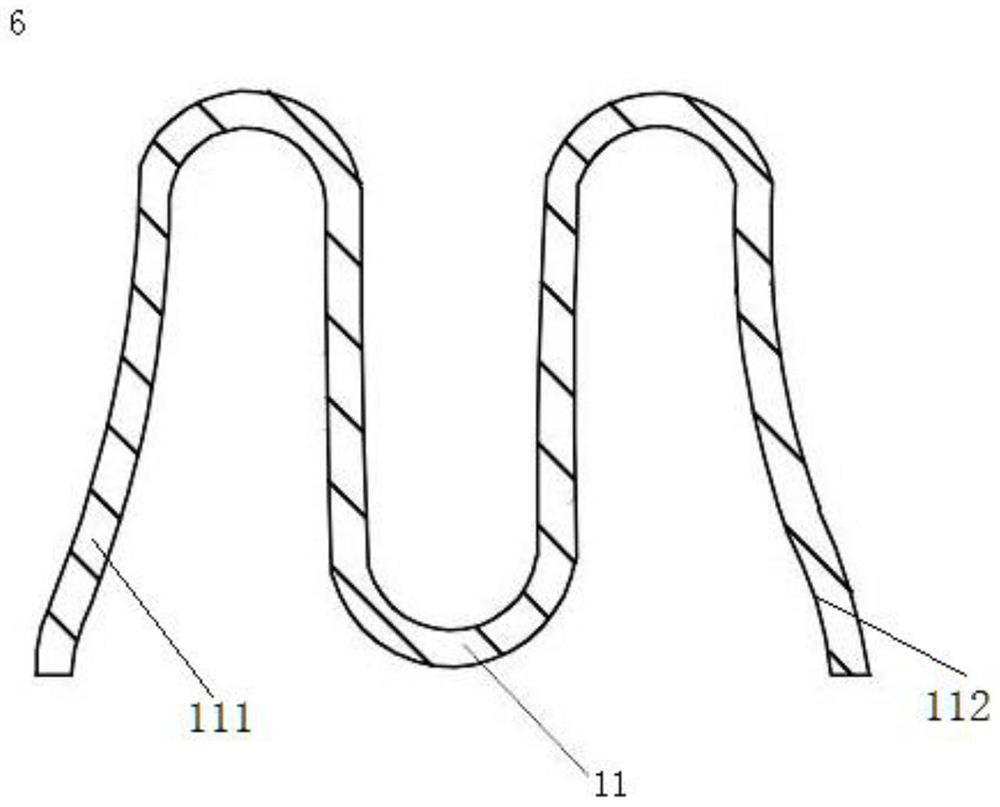

[0067] S200. Spinning along the radial center of the annular blank 1 prepared in step S100 to process an annular waist groove 11, the waist groove 11 is sunken toward the direction where the axis of the annular blank 1 is located;

[0068] S300. performing spinning processing on the parts located on both sides of the waist groove part 11 in the annular blank 1 to form a W-shaped metal sealing ring;

[0069] Wherein, before spinning the parts located on both sides of the waist groove part 11 in the annular blank 1, the waist groove part 11 is embedded in the cavity of the second mold core 2, and the inside of the waist gro...

Embodiment 2

[0107] like figure 1 , 2 As shown, the present invention also claims to protect a spinning device for a W-shaped metal sealing ring, including a waist groove spinning device 9 and two end face spinning devices for processing the waist groove part 11 in the ring blank 1 10;

[0108] Two-end surface spinning device 10 includes

[0109] The second rotating shaft 81, the second rotating shaft 81 includes a conical conical portion;

[0110] The second mold core 2, the second mold core 2 is made up of at least two split type mold cores, each split type mold core is respectively connected with the conical part of the second rotating shaft 81; The cavity that matches the shape of the groove portion 11, the first side surface that matches the shape of the first bent portion 111 of the W-shaped metal sealing ring, and the second bent portion 112 of the W-shaped metal sealing ring a second side of matching shape;

[0111] The second rotary wheel 72, the second rotary wheel 72 is alw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com