Graphic printing processing method for manufacturing of cardboard box

A processing method and cardboard box technology, applied in the post-processing of printing, printing process, printing, etc., can solve the problems of virtual pressure coating, wrinkles, air bubbles, etc., to avoid virtual pressure and wrinkles, and ensure compactness and smoothness , Solve the effect of pressing air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

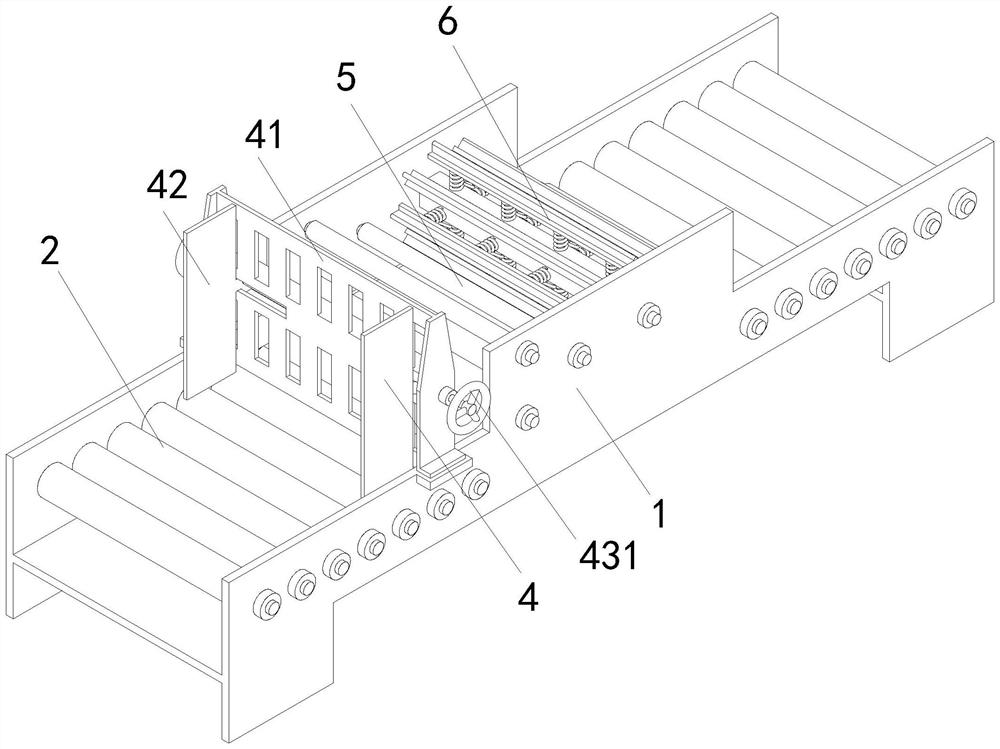

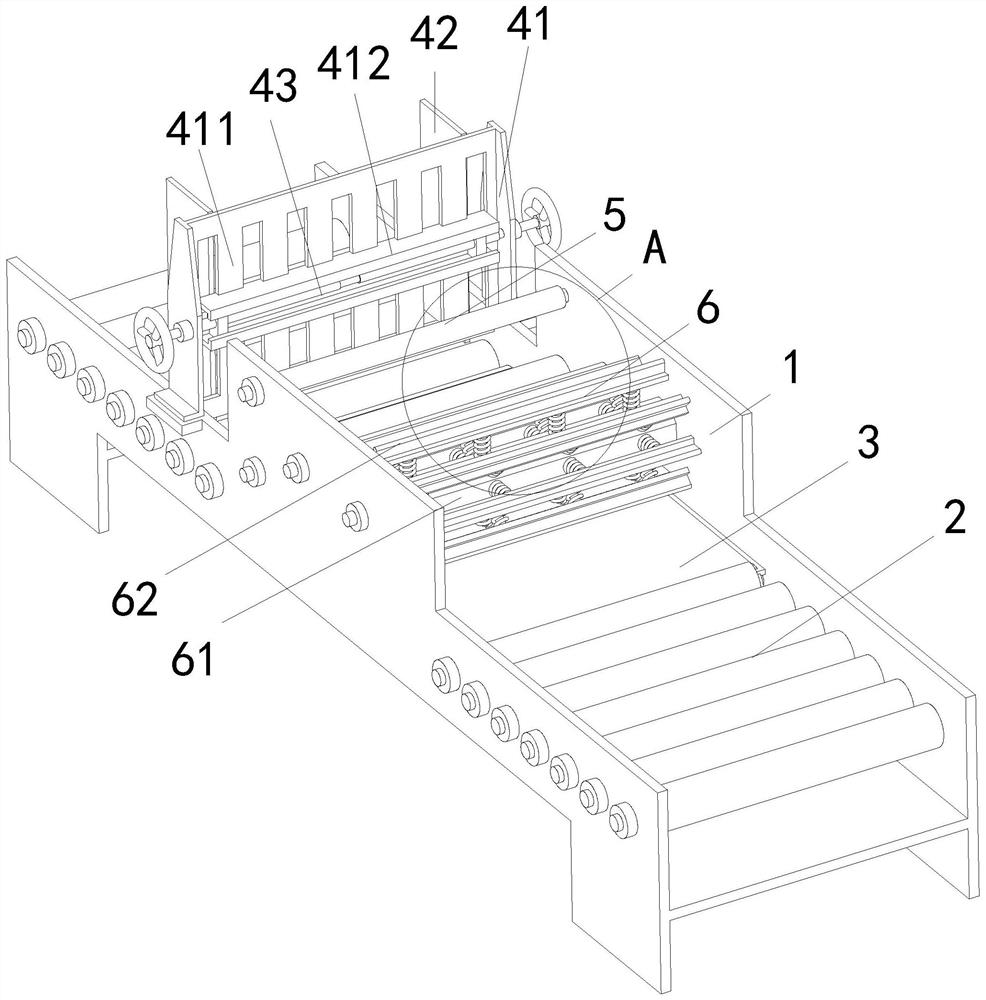

[0031] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and To facilitate its practice, but not as a limitation of the invention.

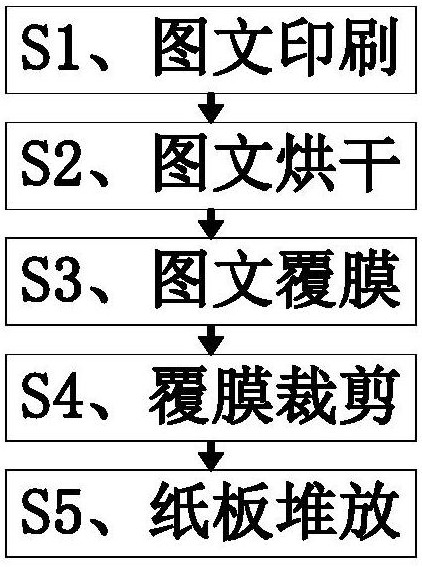

[0032] See attached Figure 1-7 Shown, a kind of cardboard box making graphic printing processing method, processing method specifically comprises the following steps:

[0033] S1. Graphic printing: Graphic printing is carried out on the surface of the cut cardboard of a certain size;

[0034] S2, graphic drying: drying the cardboard after graphic printing in step S1, so that the graphic ink printed on the surface is dried and shaped;

[0035] S3. Laminating with pictures and texts: using a cardboard box to make pictures and texts after printing, a film coatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com