Cable pulling auxiliary device with self-locking structure

An auxiliary device and self-locking technology, which is applied in the direction of transportation and packaging, thin material handling, cable laying equipment, etc., can solve the problems affecting the efficiency and quality of cable handling, the shaking of the supporting shaft cable tray, the shaking of the cable roll, etc., and achieve high efficiency. And stabilize the cable work, reduce shaking and vibration, and reduce the effect of rotating the center of gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

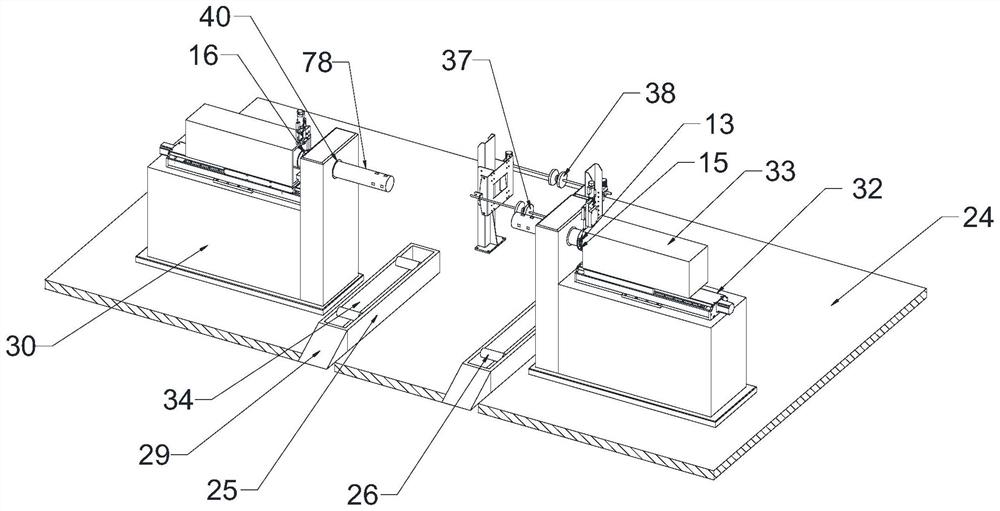

[0066] Such as Figure 1 to Figure 17 As shown, the pull wire auxiliary device with a self-locking structure includes a pull wire support frame 24;

[0067] The backguy support frame 24 has the support slide rail 25 that two intervals are arranged, is provided with the support accommodating groove 34 that runs through the top of support slide rail 25 on the support slide rail 25, is installed on the support slide rail 25 along its slide rail conveying direction and is installed with two intervals. The limit roller 26, the limit roller 26 can rotate relative to the support pulley 25;

[0068] The rear end of the support slide rail 25 is connected with an entry support 29, the top surface of the entry support 29 is inclined, and the height of the entry support 29 gradually decreases towards the direction away from the support slide rail 25;

[0069] The stay wire support frame 24 also has two mounting frames 30 respectively positioned at the outer sides of the two supporting sl...

Embodiment 2

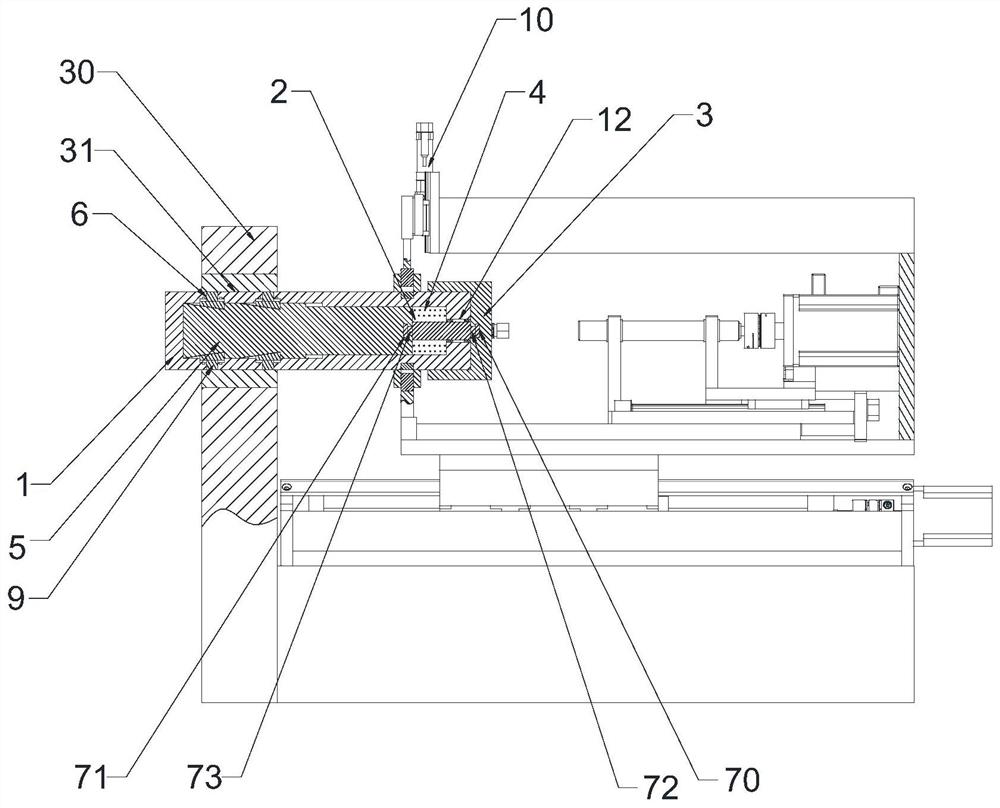

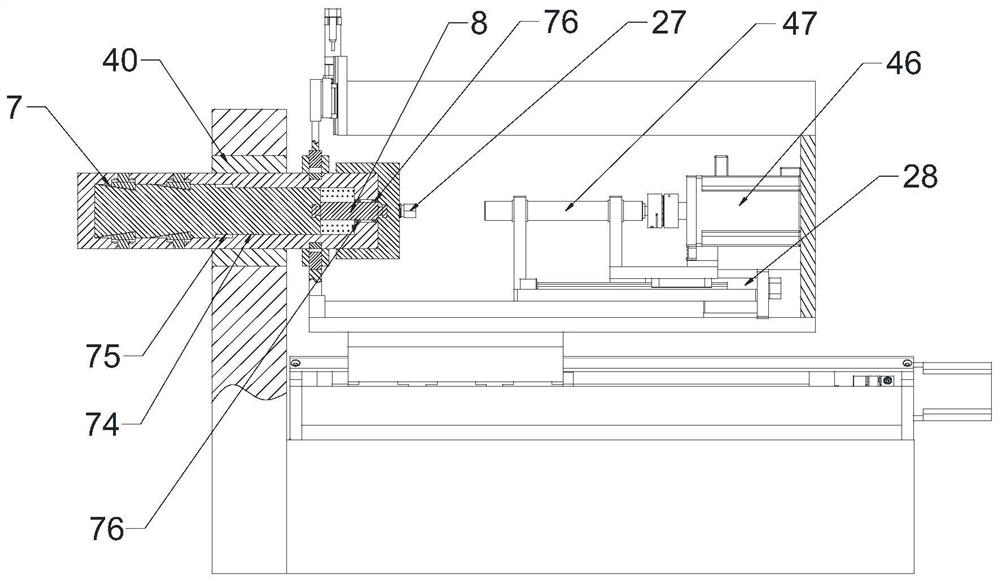

[0085] This embodiment makes the following further limitations on the basis of Embodiment 1: the locking assembly includes a shaft body 1 and an end cap 3 threaded on the outer end of the shaft body 1, and a sliding rod movable groove 2 is opened in the shaft body 1, and the shaft body 1 The outer end of the body 1 is also provided with a relief port 12 communicating with the movable groove 2 of the slide bar;

[0086] The slide bar movable groove 2 is connected with the slide bar 5 which can slide axially along the shaft body 1 in the slide bar movable groove 2 through the slide bar elastic member 4;

[0087] The slide bar 5 is provided with several sets of sliding notch groups evenly distributed along the slide bar 5 ring direction, each sliding notch group includes at least one sliding notch 7, the groove bottom of the sliding notch 7 is arranged on an inclined plane, and the sliding notch The groove depth of the port 7 gradually increases from the inner end to the outer en...

Embodiment 3

[0105] In order to realize the interlocking movement of the moving frame 33 to the locking assembly, this embodiment makes the following further limitations on the basis of Embodiment 2: the outer surface of the shaft body 1 is provided with a moving ring assembly;

[0106] The moving ring assembly has two moving rings 13 arranged at intervals, and a moving transmission ring groove 14 is formed between the two moving rings 13;

[0107] The moving frame 33 is provided with a transmission member 15 that can be placed in the moving transmission ring groove 14 and can rotate relative to the transmission ring groove 14 .

[0108] In this embodiment, through the cooperation of the transmission member 15 and the moving transmission ring groove 14 , the moving frame 33 can drive the shaft body 1 to move, and the relative rotation between the shaft body 1 and the moving frame 33 can be realized.

[0109] Such as Figure 11 to Figure 12 As shown, the transmission member 15 may include ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com