Built-in permanent magnet motor roller

A permanent magnet motor and roller technology, applied in electrical components, electromechanical devices, hoisting devices, etc., can solve the problems of poor motor protection, easy damage to the motor, and poor practicability of the hoist, and increase the number of winding layers. , the effect of increasing the traction height and increasing the width of the support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

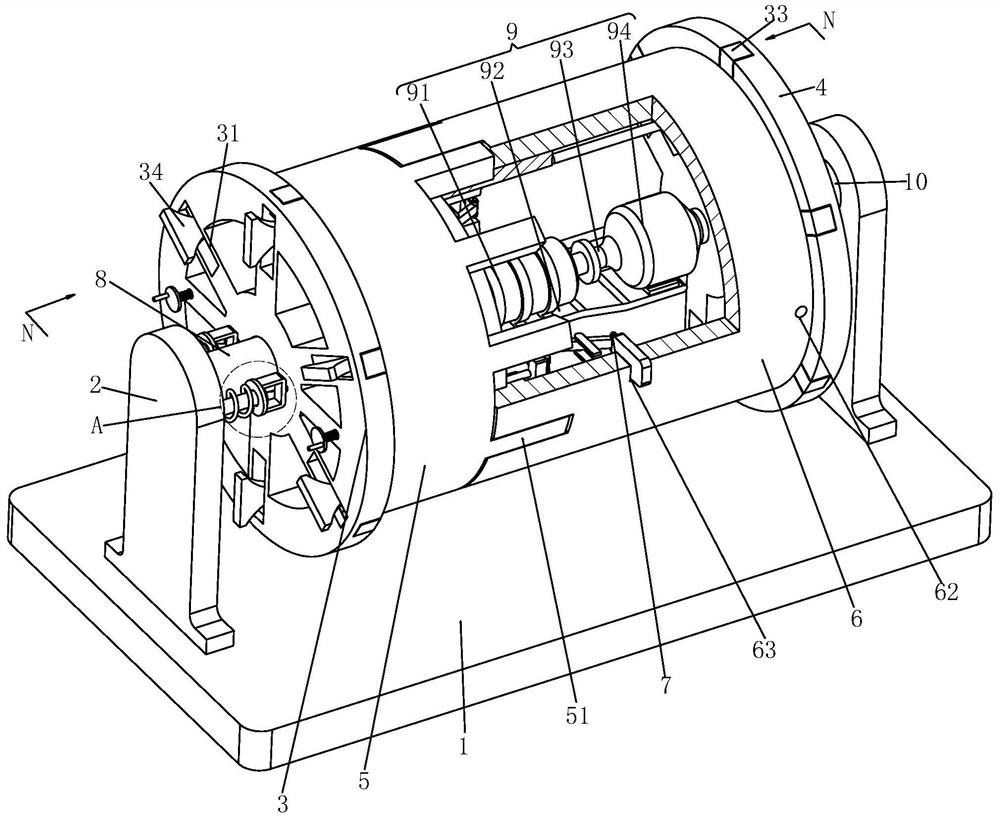

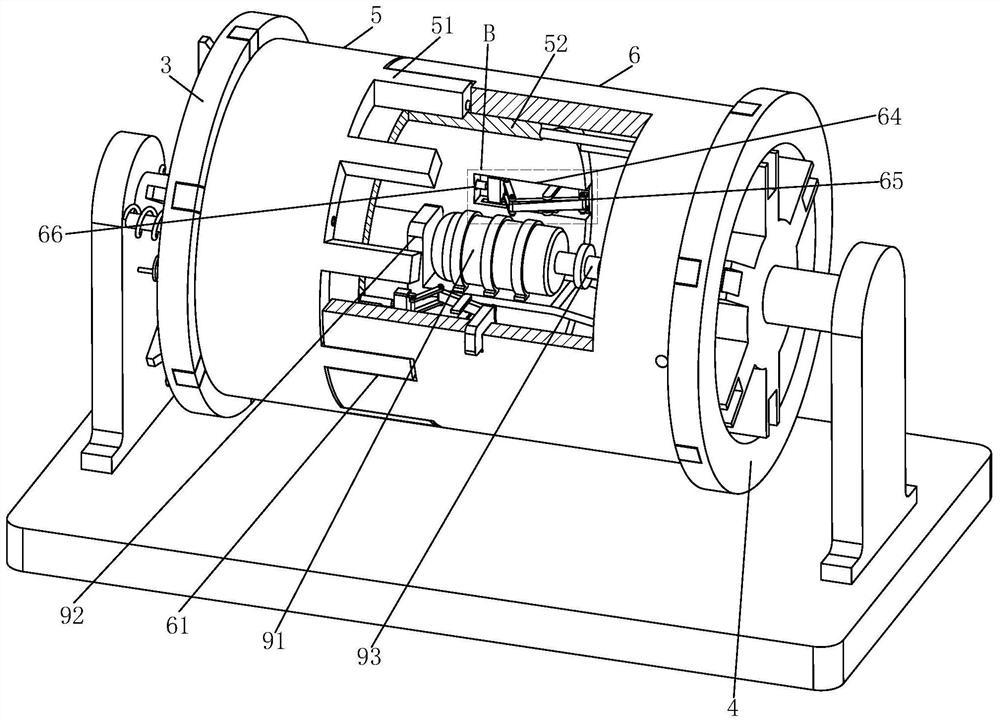

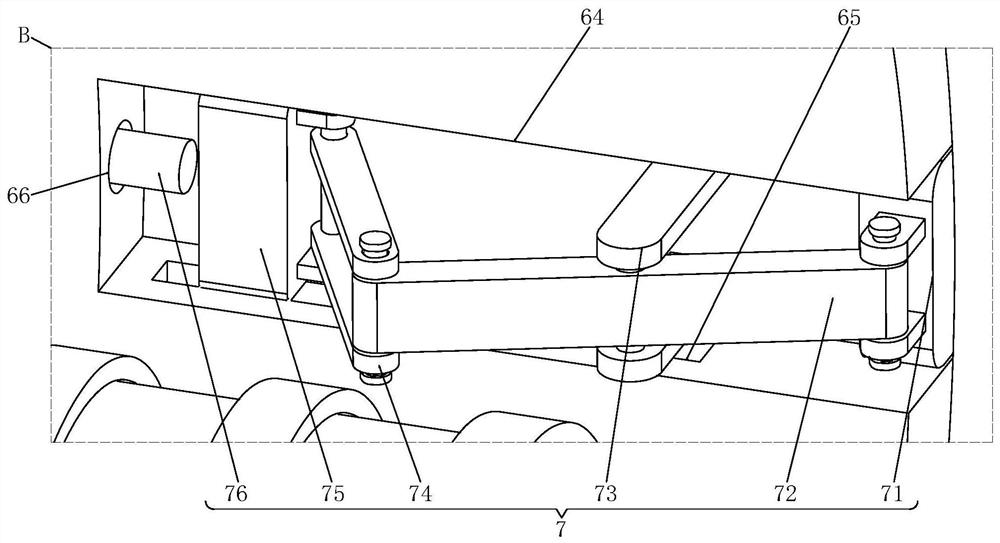

[0026] Such as Figure 1 to Figure 7 As shown, a built-in permanent magnet motor drum includes a supporting base plate 1, a supporting side plate 2, a driven rotating side drum 3, an active rotating side drum 4, a first bobbin 5, a second bobbin 6, and a lateral The driving mechanism 7, the first supporting shaft 8, the driving mechanism 9 and the second supporting shaft 10, the top of the supporting bottom plate 1 is symmetrically equipped with supporting side plates 2, and the side walls of the two supporting side plates 2 are respectively welded A support shaft 8 and a second support shaft 10, the outer wall of the first support shaft 8 is sleeved with the driven rotation side cylinder 3, the outer wall of the second support shaft 10 is sleeved w...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap