Opposite insertion type steel rail expansion joint

A technology for expansion joints and rails, which is applied to the joints of rails, tracks, roads, etc., and can solve the problems of increased maintenance costs, high cost of seamless rail construction and maintenance, and increased maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

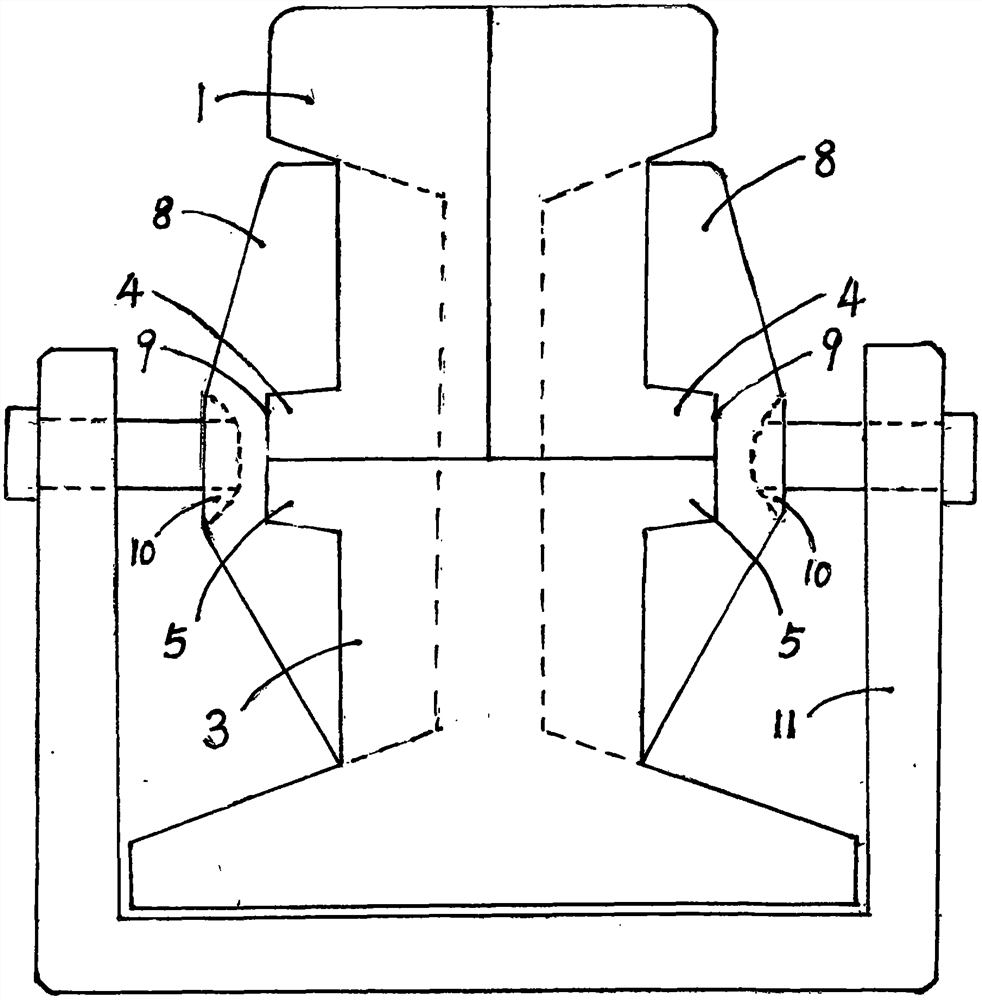

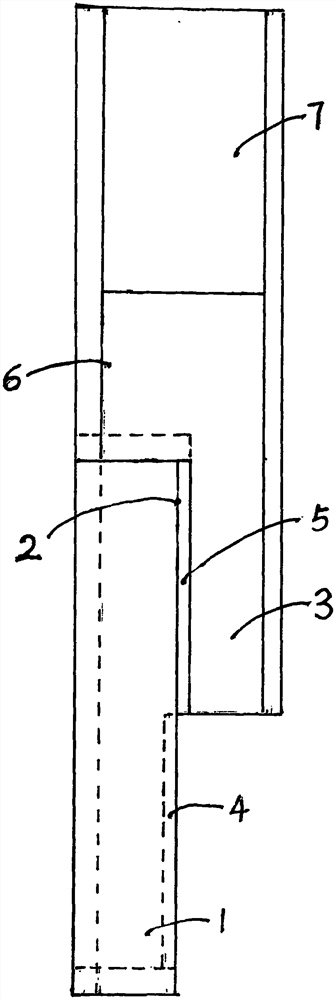

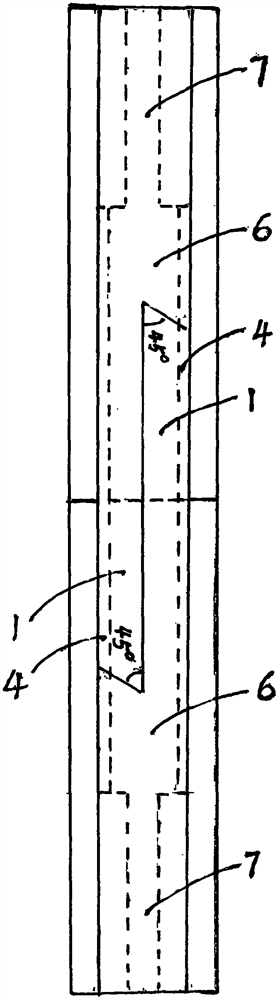

[0016] Refer to the attached picture: plug-in rail expansion joint Figure 1 to Figure 3 As shown in the figure, (1) upper connecting rail, (2) upper connecting rail groove, (3) thickened rail waist, (4) upper fixing rib, (5) lower fixing rib, (6) middle rail , (7) rear rail, (8) semi-arc slotted plate, (9) slotted plate inner groove, (10) slotted plate top thread groove, (11) C-shaped pliers.

[0017] Plug-in Rail Expansion Joint Figure 1 to Figure 3 As shown, the rear end of the upper connecting rail (1) is connected to one side in the middle of the upper half of the front end of the middle rail (6), and the other side in the middle of the upper half of the middle rail (6) is an upper connecting rail groove (2). The relative upper connecting rail (1) can be completely inserted into the relative upper connecting rail groove (2) the inside, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap