Protection automatic control device and method for dam tension wire endpoint and measuring point

A technology of automatic control device and tensioning wire, applied in the direction of measuring device, instrument, etc., can solve the problems such as the inability to flexibly adjust the steel wire protection grid, the larger hole of the wire mesh, and the inability to meet the measurement requirements, so as to achieve good protection and monitoring. Effect, low equipment cost, overcoming the effect of limited structure size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

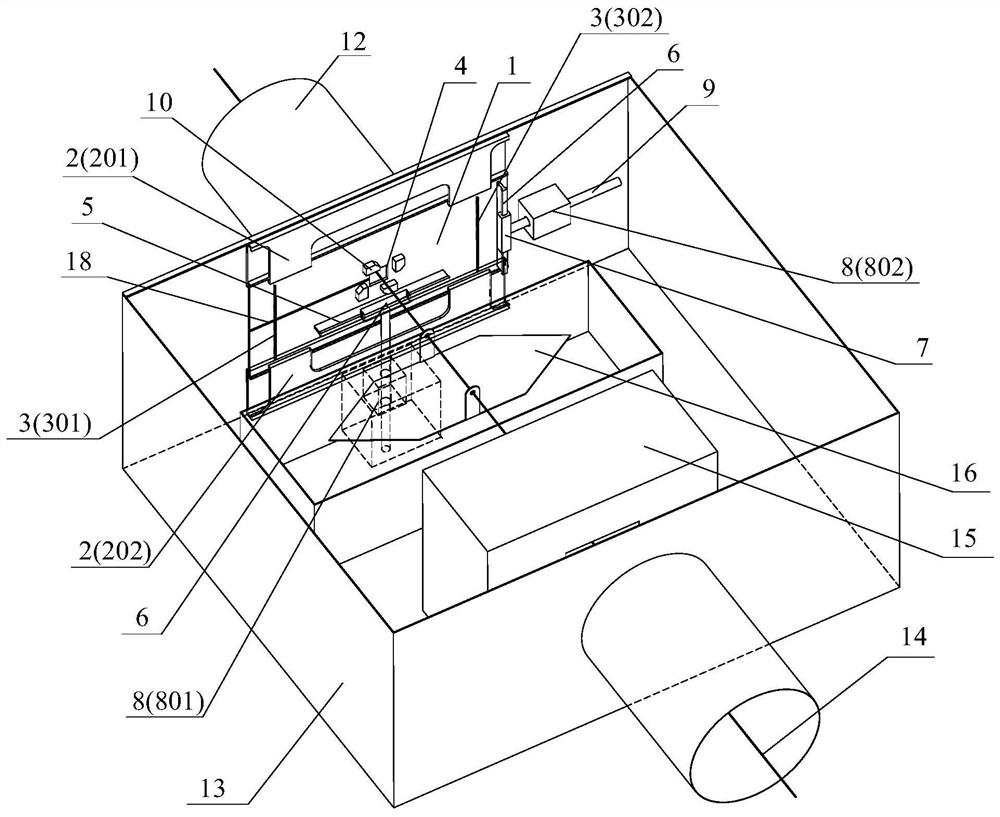

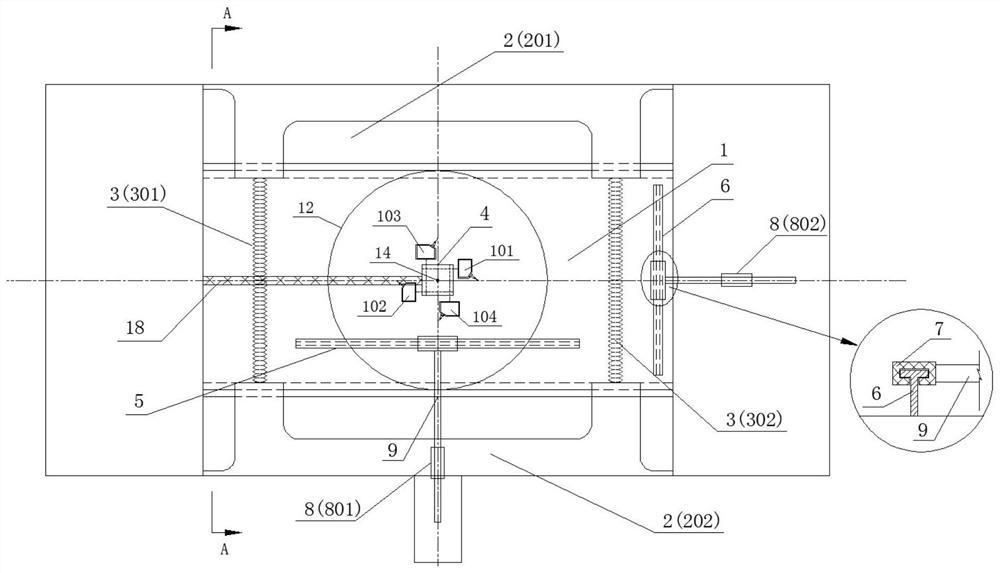

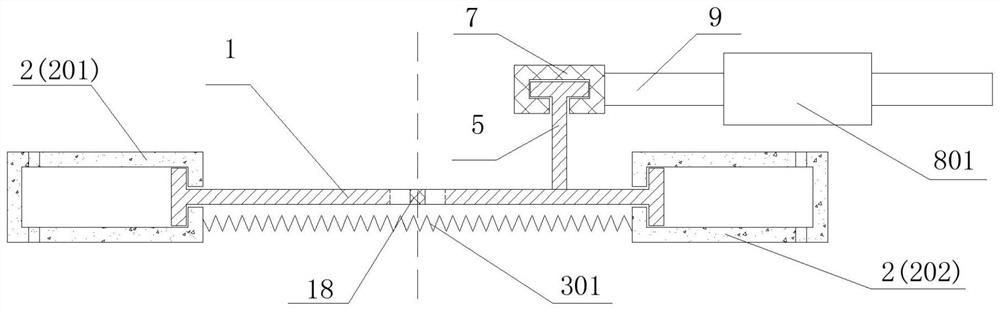

[0041] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0042] refer to Figure 1 to Figure 4 : the protective automatic control device of the dam drawing line end point and measuring point of the present invention comprises a direct drive protective plate, a follow-up protective plate 2, a compression spring 3, a wire hole 4, a lower guide rail 5, a side guide rail 6, a guide groove 7, Linear motor, thrust connecting rod 9, laser switch sensor 10 and control module 11.

[0043] Among them, the follow-up protection plate is divided into an upper follow-up protection plate 201 and a lower follow-up protection plate 202, which are closed on the left and right sides and the side of the direct drive protection plate. In the middle of the protective plate 201 and the lower follow-up protective plate 202; the bottom of the direct drive protective plate is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com