PCB CAF test module design method

A technology for testing modules and PCB boards, applied in the field of PCB board CAF testing module design, can solve problems such as adverse influencing factor analysis, short-circuit failure, poor insulation, etc., and achieve the effect of facilitating true cause analysis and screening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to enable those skilled in the art to better understand the solutions of the present invention, the following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments are only It is an embodiment of a part of the present invention, but not all embodiments.

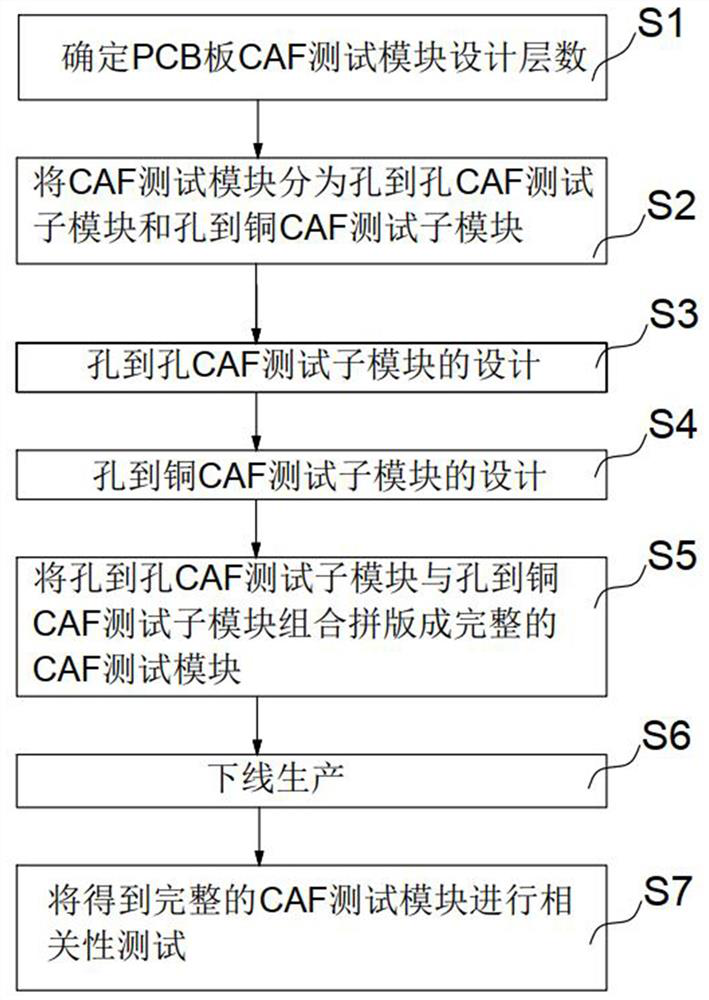

[0024] Such as figure 1 Shown, a kind of PCB board CAF test module design method of the present embodiment comprises the following steps:

[0025] S1. Determine the number of design layers of the PCB board CAF test module;

[0026] S2. The CAF test module is divided into a hole-to-hole CAF test sub-module and a hole-to-copper CAF test sub-module;

[0027] S3, the design of the hole-to-hole CAF test submodule: including the first inner layer graphic design and the first outer layer graphic design, the first inner layer graphic design includes the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com