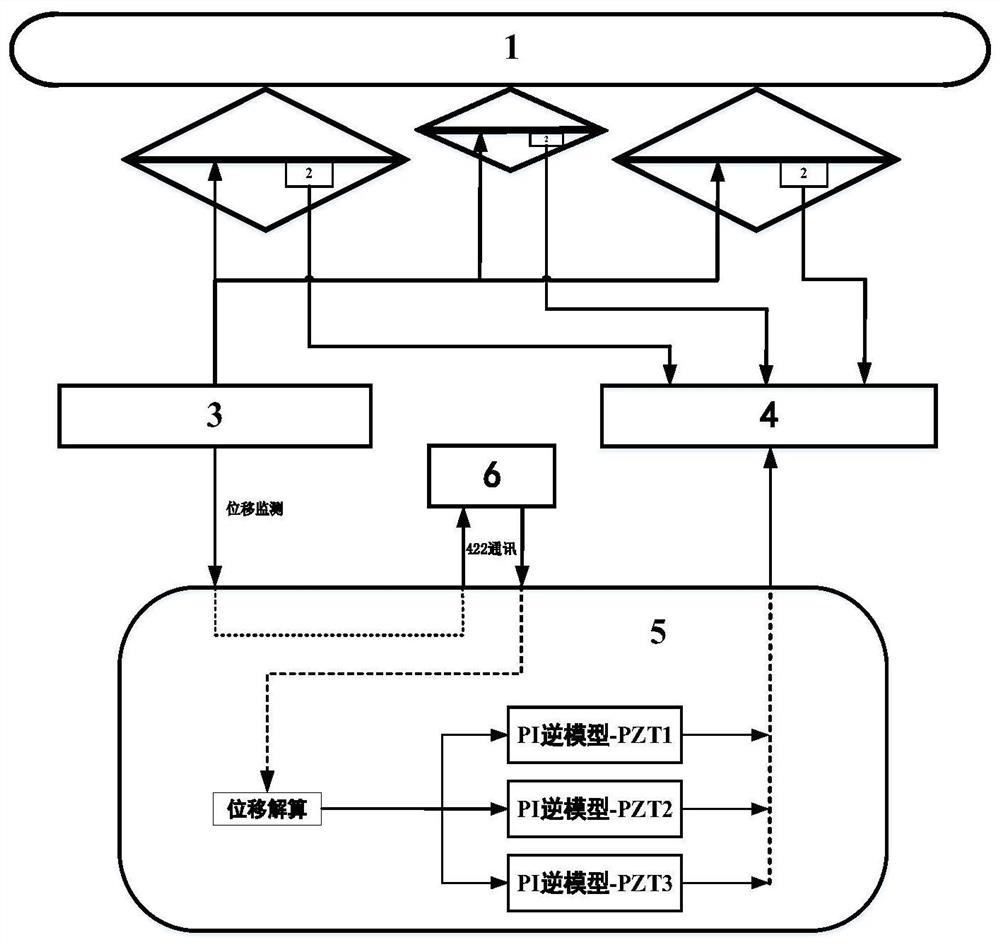

Three-point piezoelectric driving fast steering mirror hysteresis compensation control system based on FPGA

A technology of compensation control and piezoelectric ceramic drive, which is applied in general control system, control/adjustment system, program control, etc., can solve the adverse effects of fast-swing mirror compensation accuracy, reduce the performance of image stabilization system, etc., and achieve real-time synchronization and multiple Effects of piezoelectric compensation and control, reducing calculation delay, and improving system response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

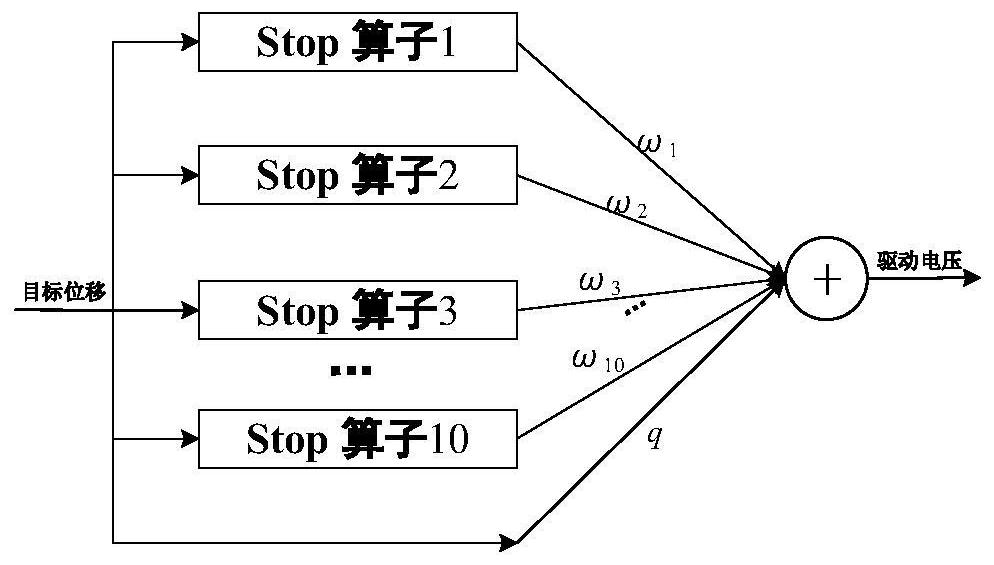

[0015] The present invention adopts the inverse model hysteresis compensation method to eliminate the hysteresis nonlinearity of piezoelectric ceramics, uses the PI hysteresis inverse model to inversely solve the target displacement of the piezoelectric ceramic actuator obtained by the displacement calculation module, and obtains the driving voltage through 16bits D / A The output of the acquisition circuit is driven by the piezoelectric ceramic drive power supply to drive the piezoelectric ceramic actuator, so as to achieve the linearization of the target output and the actual output, such as figure 2 shown.

[0016] The input of the conventional hysteresis model is the driving voltage, and the output is the displacement, while the input of the inverse hysteresis model is the displacement, and the output is the driving voltage. Aiming at the establishment of the piezoelectric hysteresis inverse model, in order to avoid the complicated inversion process and the constraints on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com