Automatic crushing device for blocky rare earth

A crushing device and rare earth technology, applied in grain processing and other directions, can solve the problems of difficulty in collecting rare earths, inability to screen out rare earths, and inability to stop crushing rare earths instantly, achieving the effect of convenient collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

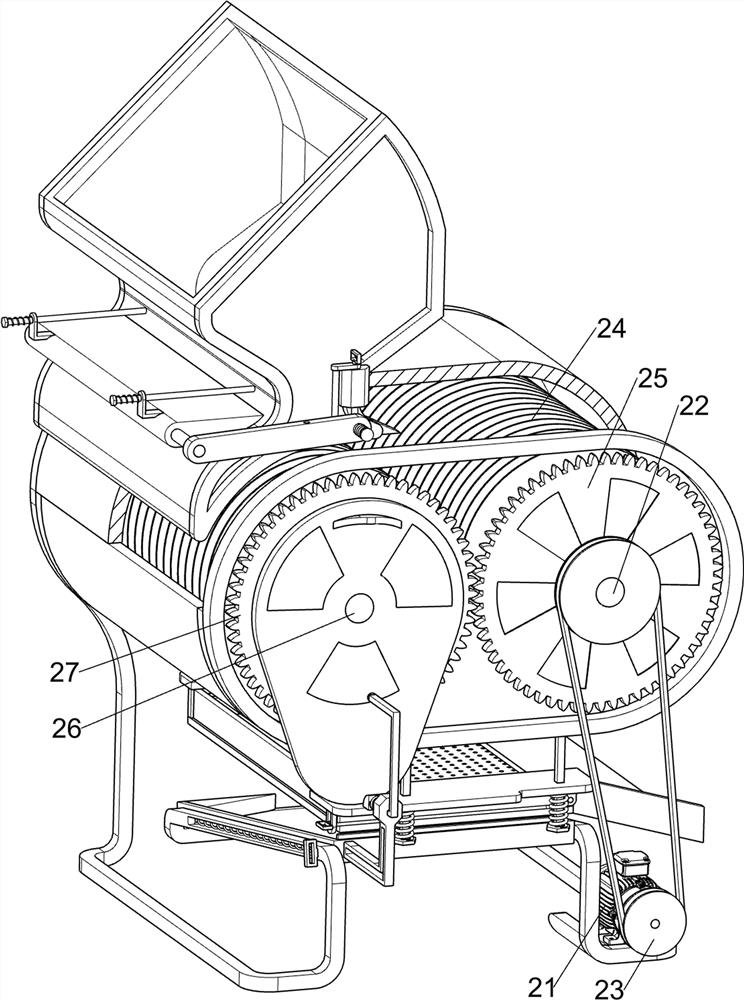

[0031] A kind of massive rare earth automatic crushing device, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, it includes a support frame 1, a blanking chute frame 11, a material receiving plate 12, a crushing mechanism 2, and a feeding mechanism 3. A receiving plate 12 is connected between the sides, a crushing mechanism 2 is arranged on the support frame 1 , and a feeding mechanism 3 is arranged between the lower part of the unloading chute frame 11 and the crushing mechanism 2 .

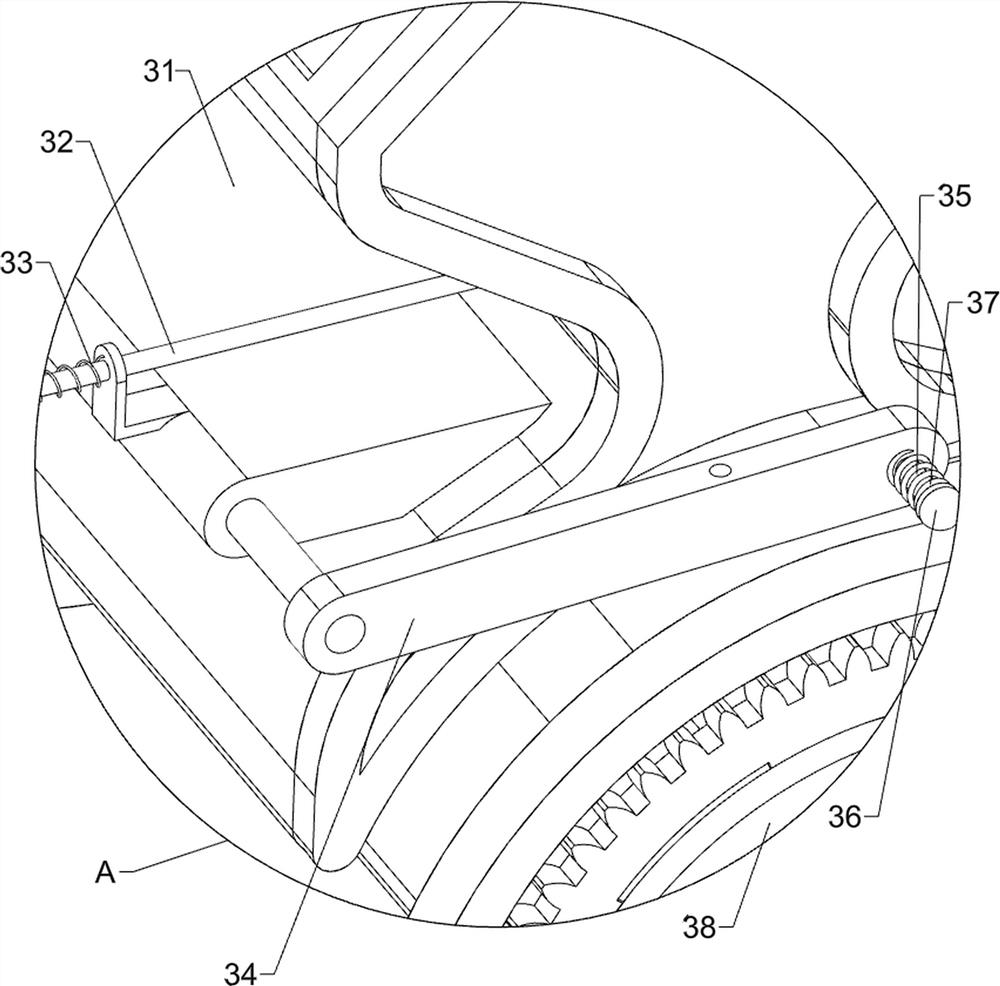

[0032] The crushing mechanism 2 includes a motor 21, a first rotating shaft 22, a transmission group 23, a cutting wheel 24, a first gear 25, a second rotating shaft 26 and a second gear 27, and a motor 21 is installed on the right front side of the support frame 1 bottom, supporting The right side of the upper part of the frame 1 is rotationally connected with a first rotating shaft 22, and a transmission group 23 is connected between the front side of the first rotating shaft...

Embodiment 2

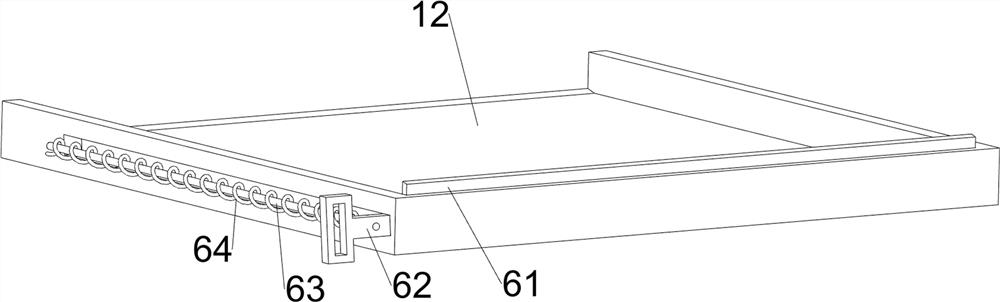

[0036] On the basis of Example 1, such as figure 1 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9 As shown, a screening assembly 4 is also included, and the screening assembly 4 includes a fourth connecting rod 41, a sieve tray plate 42, a third spring 43, a fixed rod 44, a fifth connecting rod 45, a second wedge block 46, a fourth spring 47. The connection block 48 and the projection 49, the front and rear sides of the middle part of the support frame 1 are symmetrically connected with the fourth connecting rod 41, and the fourth connecting rod 41 is slidably connected with the sieve groove plate 42, and the sieve groove plate 42 and the cam 38 cooperate with each other, the third spring 43 is symmetrically connected to the left and right sides between the lower side of the fourth connecting rod 41 and the sieve plate 42, and the third spring 43 is set on the fourth connecting rod 41, and the front part of the receiving plate 12 The left side is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com