Fluff processing device for fabric production

A processing device and fluff technology, applied in the field of fabric production, can solve problems such as dense connections, fire hazards, and inconvenient manual cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

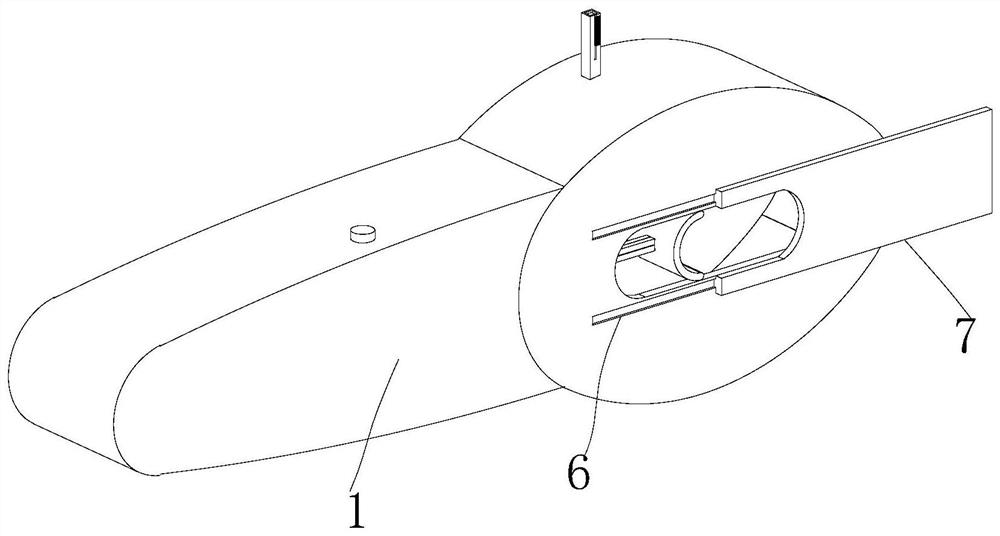

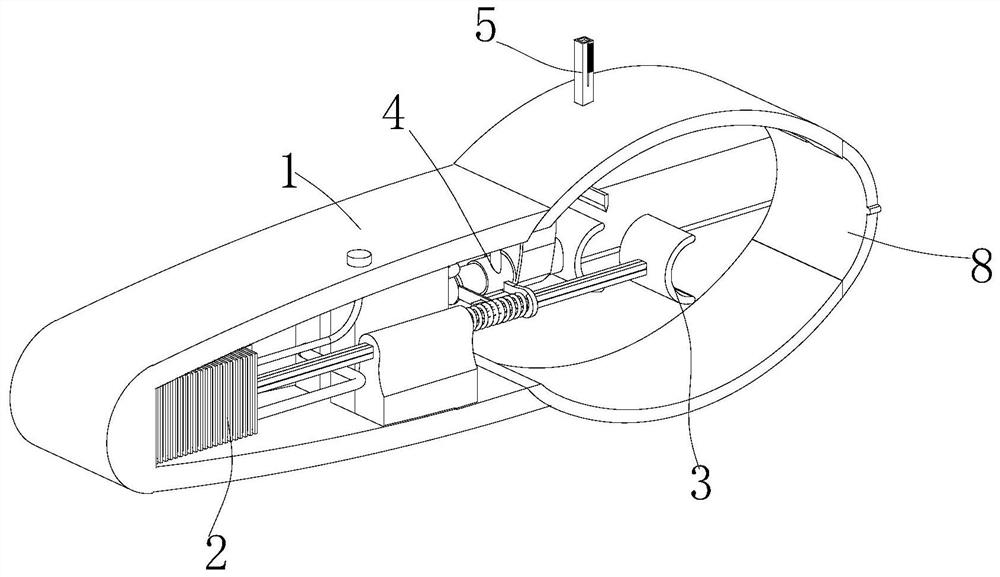

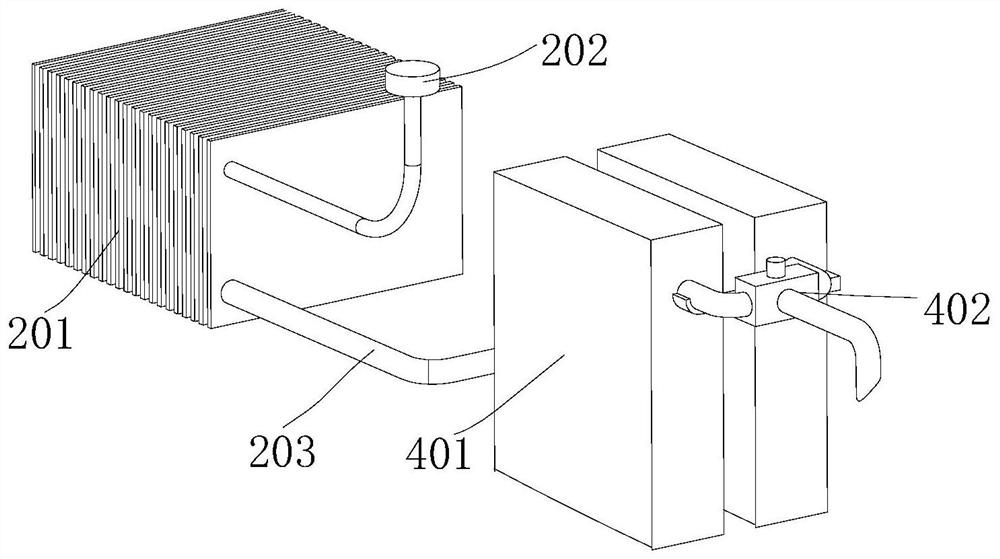

[0024] Embodiment one, such as Figure 1-6 As shown, the hand-held box 1 is included, the inner rear end of the hand-held box 1 is fixedly equipped with an airbag mechanism 2, and the front end side of the airbag mechanism 2 is provided with a compression mechanism 3, the compression mechanism 3 is fixedly connected with the hand-held box 1, and the front of the hand-held box 1 A limiting groove 6 is provided, and a sealing plate 7 is slidably connected to the inside of the limiting groove 6 . By arranging the limit groove 6 and the sealing plate 7, the installed device can be sealed. The front end cross section of the hand-held box 1 is in the shape of a "C", and the front end of the hand-held box 1 is rotatably connected with a half-ring plate 8. Such an arrangement is convenient for the device to be sleeved on the outer surface of the rotating shaft, and the splashing of the sprayed liquid can be avoided by setting the half-ring plate 8 to achieve a sealing effect.

[0025...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com