Multi-axis servo matching method and device for AC type double-swing-head five-axis linkage machine tool

A five-axis linkage machine tool and matching method technology, which is applied to milling machines, milling machine equipment, milling machine equipment details, etc., can solve the problem that there is no better servo matching optimization method for multi-axis mechanical systems participating in motion, and achieve reduction of optimization costs. Effects with strong operability and low complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

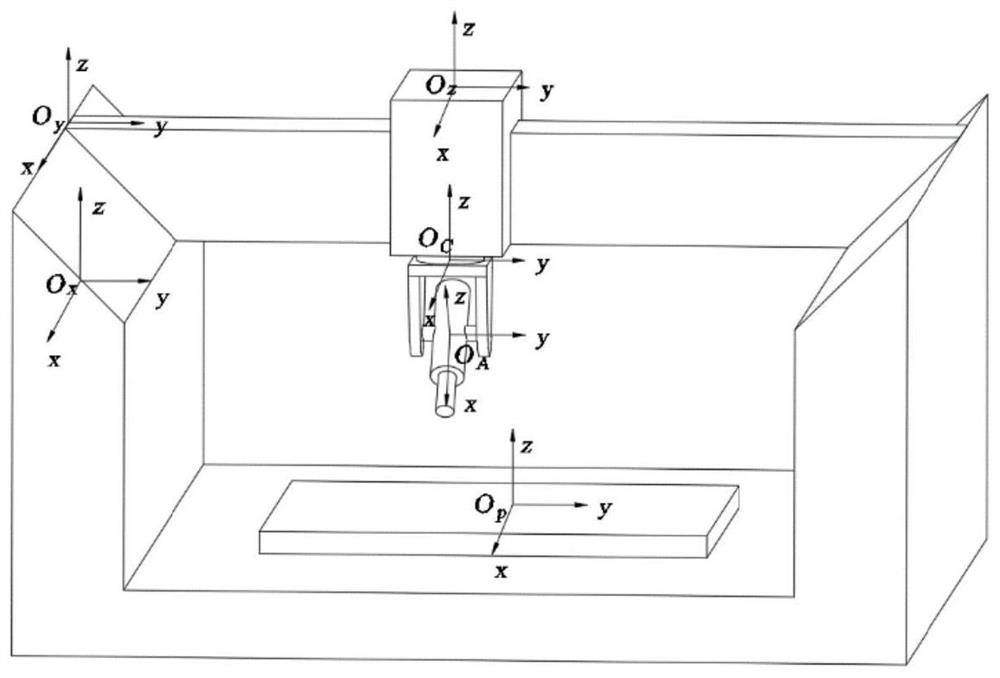

[0051]Embodiments of the present invention will be described below with reference to the accompanying drawings. Those skilled in the art would recognize that the described embodiments can be modified in various ways or combinations thereof without departing from the spirit and scope of the invention. Accordingly, the drawings and description are illustrative in nature and not intended to limit the scope of the claims. Also, in this specification, the drawings are not drawn to scale, and like reference numerals denote like parts.

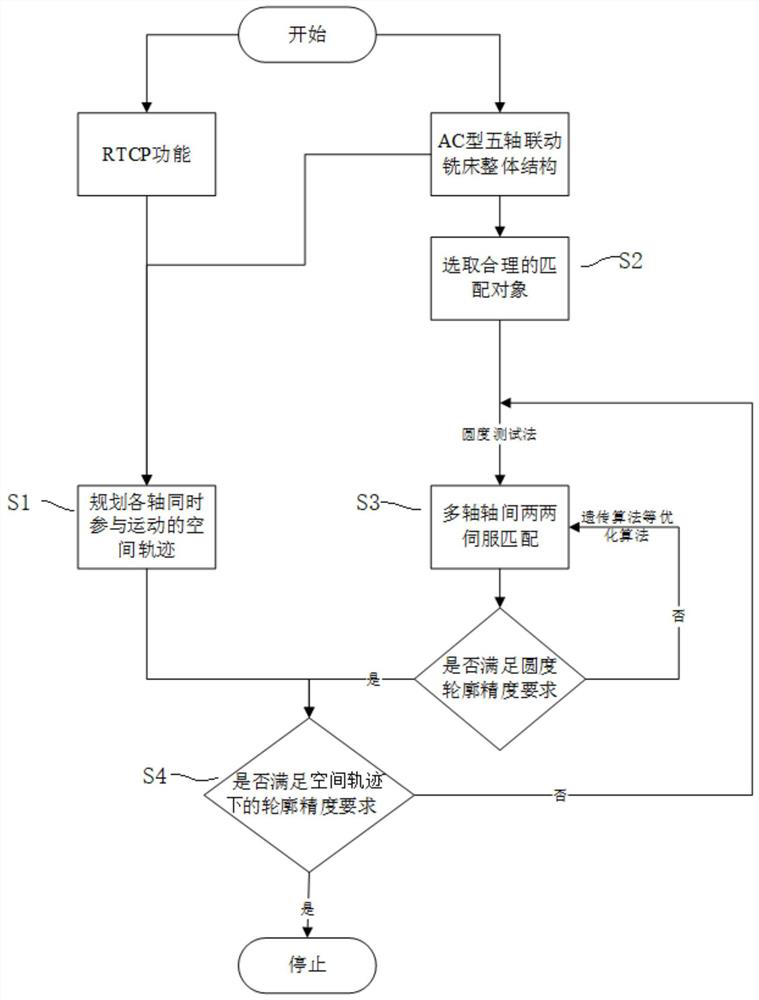

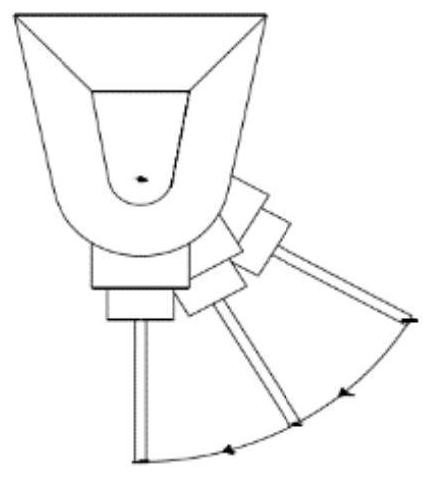

[0052] Servo matching: Servo matching refers to making the dynamic response characteristics of each single-axis system better by adjusting the parameters of each single-axis servo system that participates in the processing of the test piece at the same time under the premise of ensuring the stability and controllability of each single-axis servo feed system. Matching, thereby improving the contour machining accuracy of the workpiece. Adjusting the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com