Nut locking assembling machine and assembling method thereof

An assembly machine, nut lock technology, applied in packaging, labeling machine, transportation and packaging, etc., can solve the problems of low work efficiency, low degree of automation, high labor cost, improve production efficiency, reduce quantity and save labor costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

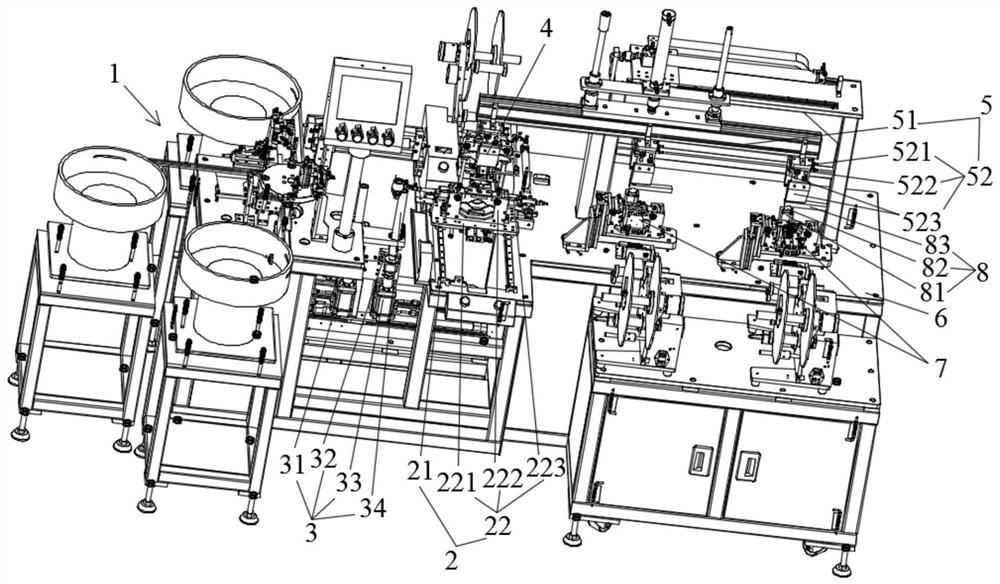

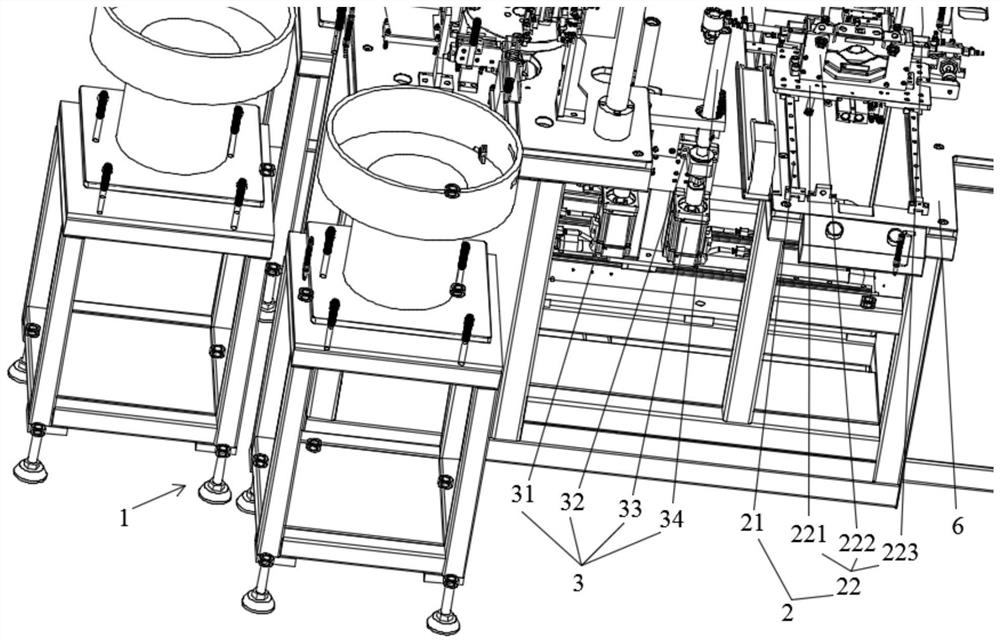

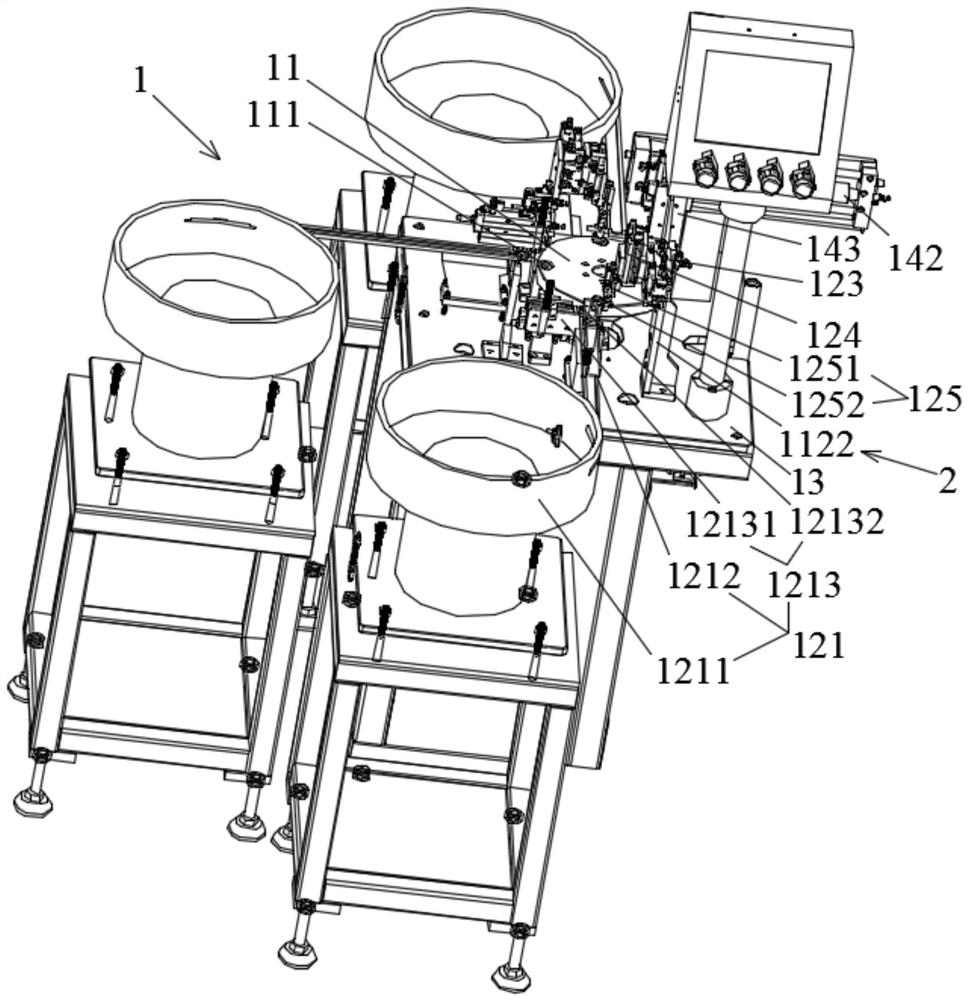

[0049] Such as Figure 1-6 As shown, a nut locking assembly machine includes a first feeding device 1, a second feeding device 2, a locking device 3, a first labeling device 4, a grabbing device 5, a frame 6 and a plurality of second labeling devices 7. The first feeding device 1, the second feeding device 2, and a plurality of second labeling devices 7 are arranged in sequence, the first labeling device 4 is set corresponding to the second feeding device 2, and the grabbing device 5 is simultaneously connected with the second feeding device 2 , a plurality of second labeling devices 7 are correspondingly arranged, and the locking device 3 is correspondingly arranged with the first feeding device 1 and the second feeding device 2 at the same time, the second feeding device 2, the locking device 3, the first labeling device 4, the grabbing The device 5 and a plurality of second labeling devices 7 are all arranged on the frame 6, and the first feeding device 1 is used to stack n...

Embodiment 2

[0073] Such as Figure 1-6 Shown, a kind of assembly method of the nut locking assembly machine of embodiment 1 comprises the following steps:

[0074] S1. The first feeding device 1 stacks spring washers and flat washers on the nuts in sequence, and transports the folded spring washers, flat washers and nuts to the locking device 3; in practical applications, different materials ( Flat pads, spring washers, nuts, etc.) are loaded through different feeding units 12; in operation, the first linear module 123 can also be set as a cylinder according to the needs of actual work; the distributing mechanism 121 will be stacked on the The materials together are dispersed so that the materials are output one by one in an orderly manner, and then the first linear module 123 works to drive the first telescopic mechanism 124 to move, and the material clamping mechanism 125 connected to the output end of the first telescopic mechanism 124 is also driven moving, so that the clamping mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com