A high-temperature-resistant wave-absorbing structure integrated ceramic matrix composite material and its preparation method

A composite material, high temperature resistant technology, applied in the stealth field of high-speed aircraft, can solve the problems of high dielectric constant, wave absorbing performance and mechanical performance need to be further improved, complex structure, etc., to achieve the effect of saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The service environment is: the airflow velocity is Mach 3, the maximum airflow temperature is 1500°C (the average temperature is 1300°C), and the reflectivity in the X-band range is better than -10dB; the tensile strength of the material is 200MPa; (the above parameters are Boundary conditions of the model)

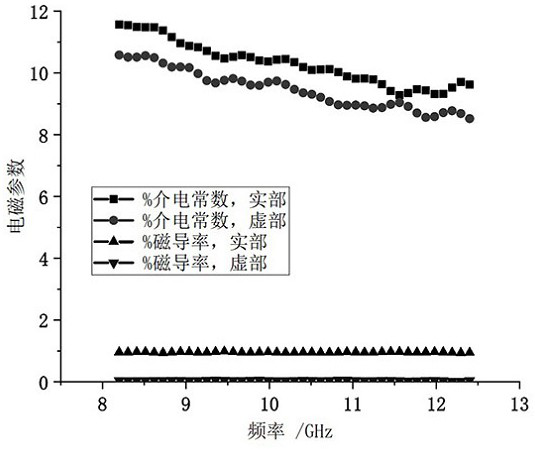

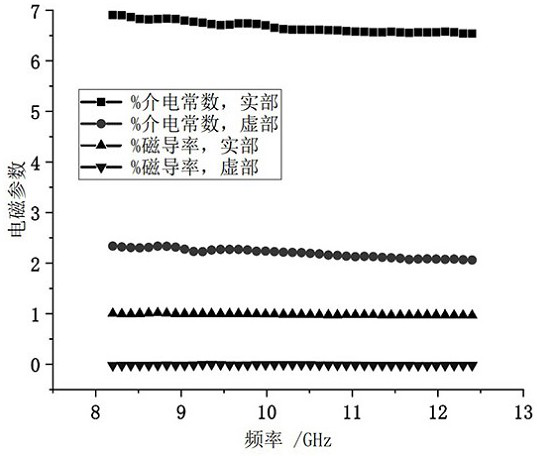

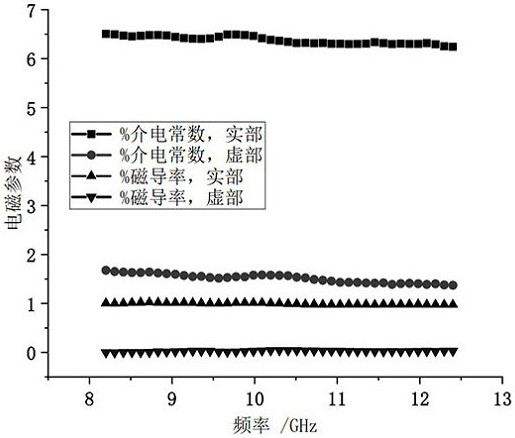

[0056] COMSOL Multiphysics and finite element full-wave analysis software HFSS software are used for simulation calculation. According to the actual situation, since the electromagnetic wave is projected from infinity to the surface of the material, it can be regarded as a plane wave. Therefore, during the simulation, the incident electromagnetic wave at the port is set as a plane wave. , the electric field polarization direction is parallel to the fiber axis, and the material itself has a periodic structure in the X direction, so periodic boundary conditions are set on the left and right sides of the model. The bottom end of the model is set as a perfect electric...

Embodiment 2

[0067] The service environment is: the airflow velocity is Mach 5, the maximum airflow temperature is 1500 degrees Celsius (the average temperature is 1300 degrees Celsius), and the reflectivity in the X-band range is better than -10dB; the tensile strength of the material is 200MPa;

[0068] COMSOL Multiphysics and finite element full-wave analysis software HFSS software are used for simulation calculation. According to the actual situation, since the electromagnetic wave is projected from infinity to the surface of the material, it can be regarded as a plane wave. Therefore, during the simulation, the incident electromagnetic wave at the port is set as a plane wave. , the electric field polarization direction is parallel to the fiber axis, and the material itself has a periodic structure in the X direction, so periodic boundary conditions are set on the left and right sides of the model. The bottom end of the model is set as a perfect electric conductor to be equivalent to a ...

Embodiment 3

[0079] Other conditions are the same as in Example 1, except that the weaving method is 45° twill weaving, and the detailed arrangement relationship between fibers is the alternate mixed weaving mode of lossy fibers and wave-transparent fibers; after weaving is completed, a mixed weaving prefabricated body is obtained ; After impregnation-cracking, the properties of the resulting product are shown in Table 6;

[0080] .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com