Preparation method of cellulose aerogel-based efficient air filtering membrane

A high-efficiency air filtration, aerogel-based technology, applied in separation methods, dispersed particle filtration, chemical instruments and methods, etc., can solve the problems of high material cost, unfavorable for practical application, large fiber diameter, etc. Conducive to mass production and promotion, the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

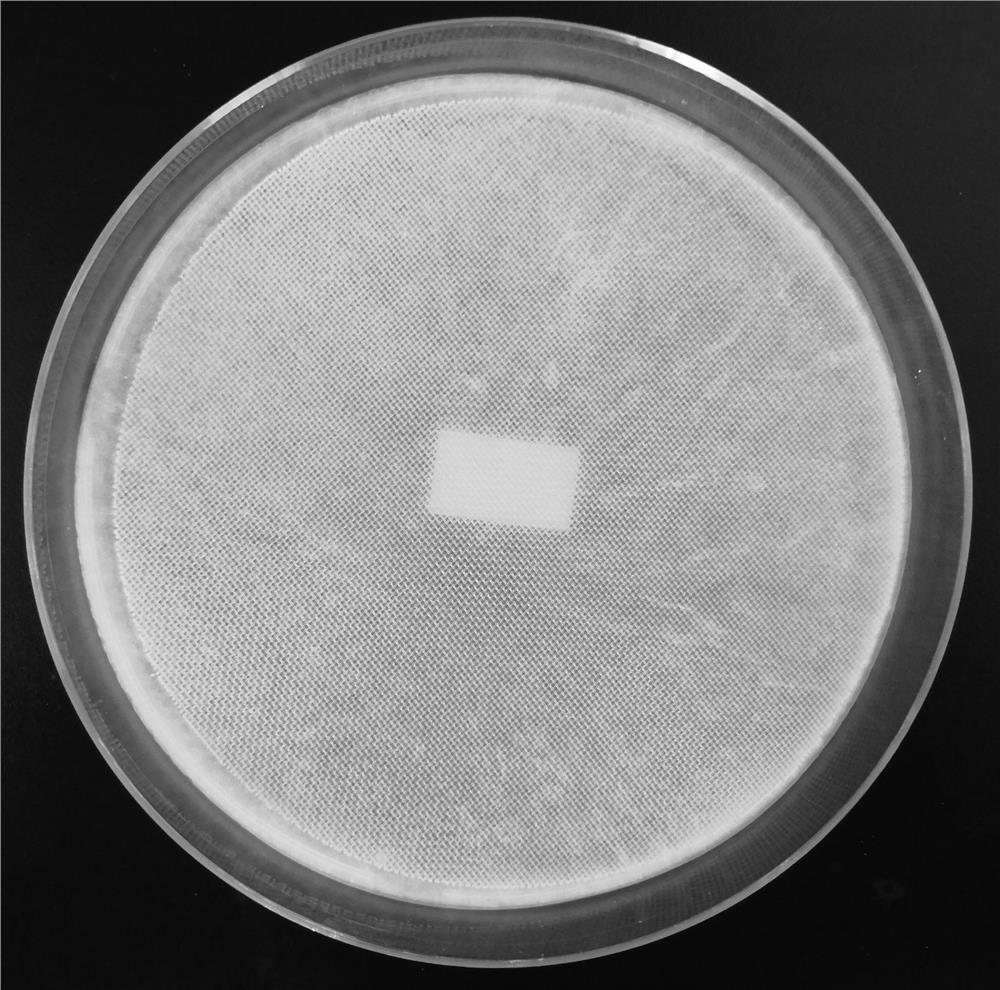

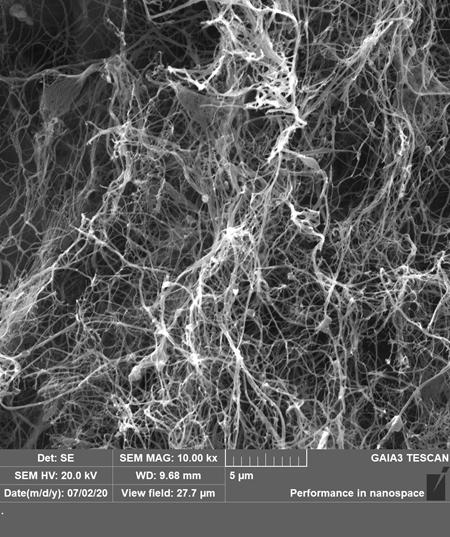

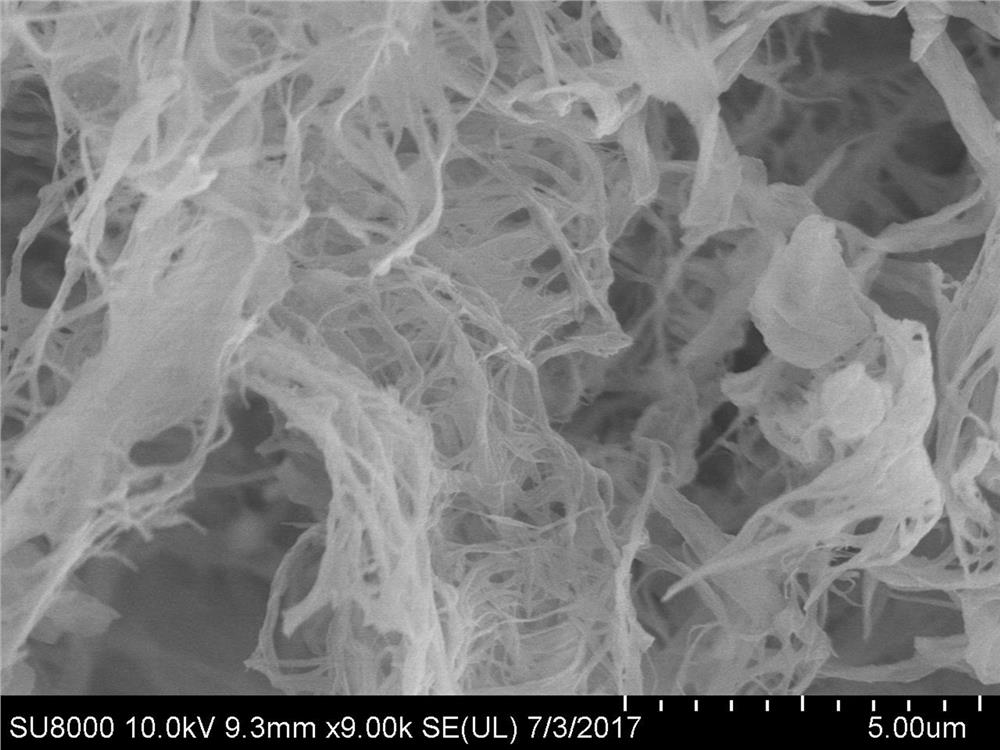

Image

Examples

Embodiment 1

[0026] Example 1, the mass fraction is 0.005% microbial cellulose airgel-based preparation of high-efficiency air filtration membrane.

[0027] Step 1, pretreatment of pure microbial cellulose hydrogel block:

[0028] Wash 50g of microbial cellulose hydrogel (food-grade coconut pieces) with excess deionized water for 4h to wash off the sugar, react with 4% sodium hydroxide solution 500mL at 80°C for 8h, and then use deionized Wash to neutral;

[0029] Wherein, the alkaline solution is sodium hydroxide solution, potassium hydroxide solution, sodium carbonate solution, etc., preferably sodium hydroxide solution.

[0030] Step 2, oxidation of microbial cellulose:

[0031] Add water to the microbial cellulose hydrogel block prepared in step 1 and beat it into a slurry with a cooking machine, centrifuge to make the concentration of the microbial cellulose slurry 2.0%, and then add 0.0065g TEMPO, 0.040g sodium bromide and 0.58mL sodium hypochlorite in sequence Add 20.0 mL of cent...

Embodiment 2

[0039] Example 2, preparation of 0.01% microbial cellulose airgel-based high-efficiency air filtration membrane with a mass fraction of 0.01%.

[0040] Step 1, pretreatment of pure microbial cellulose hydrogel block:

[0041] Wash 50g of microbial cellulose hydrogel (food-grade coconut pieces) with excess deionized water for 4h to wash off the sugar, react it with 4% sodium hydroxide solution at 85°C for 7.5h, and then use it Ionic water wash to neutral;

[0042] Wherein, the alkaline solution is sodium hydroxide solution, potassium hydroxide solution, sodium carbonate solution, preferably sodium hydroxide solution.

[0043] Step 2, oxidation of microbial cellulose:

[0044] Add water to the microbial cellulose hydrogel block prepared in step 1 and beat it into a slurry with a beater, centrifuge to make the concentration of the microbial cellulose slurry 2.2%, and then add 0.0096g TEMPO, 0.06g sodium bromide and 0.87mL sodium hypochlorite in sequence Add it to 30.0 mL of ce...

Embodiment 3

[0051] Embodiment 3, the mass fraction is the preparation of 0.015% microbial cellulose airgel-based high-efficiency air filtration membrane.

[0052] Step 1, pretreatment of pure microbial cellulose hydrogel block:

[0053] Wash 50g of microbial cellulose hydrogel (food-grade coconut pieces) with excess deionized water for 4h to wash off the sugar, react with 500mL of 5% sodium hydroxide solution at 90°C for 7h, and then use deionized Wash to neutral;

[0054] Wherein, the alkaline solution is sodium hydroxide solution, potassium hydroxide solution, sodium carbonate solution, preferably sodium hydroxide solution.

[0055] Step 2, oxidation of microbial cellulose:

[0056] Add water to the microbial cellulose hydrogel block prepared in step 1 and beat it into a slurry with a beater, centrifuge to make the concentration of the microbial cellulose slurry 2.5%, and then mix 0.0128g TEMPO, 0.08g sodium bromide and 1.16mL sodium hypochlorite in sequence Add 40.0 mL of centrifuge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com