Carbon fiber paper injection air blowing plate

A technology of paper blowing board and carbon fiber, which is applied in the field of papermaking, can solve the problems of long time-consuming, unsafe, and low efficiency of cotton thread threading, and achieve the effects of eliminating potential safety hazards, reducing labor intensity, and avoiding danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

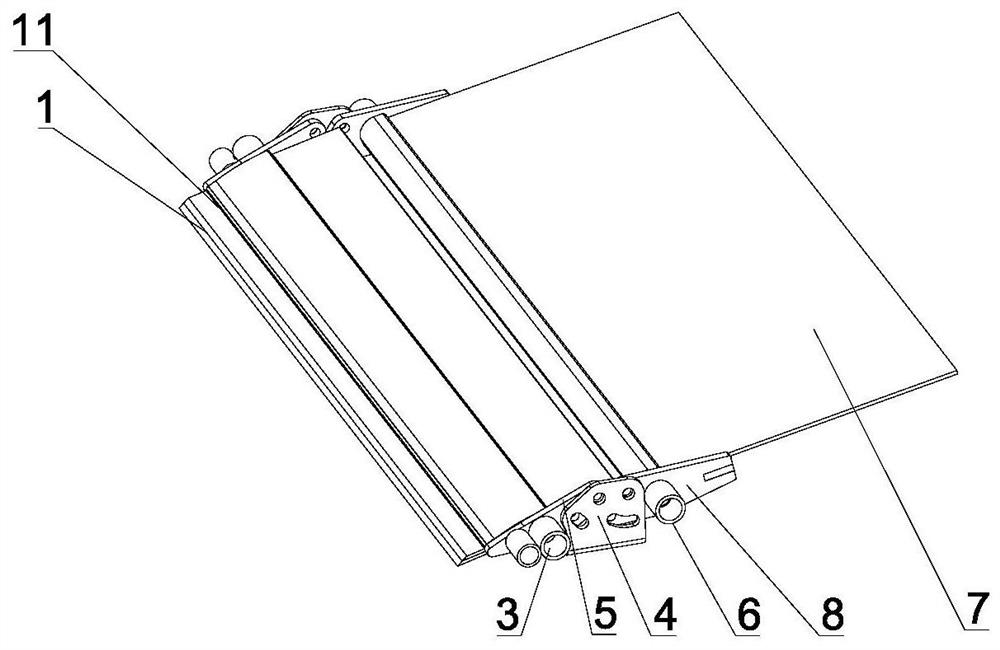

[0021]Example:figure 1 As shown, it is a schematic perspective view of the present invention, which is provided with a front windpad assembly and a rear wind plate assembly, the front wind plate assembly, and the rear wind plate assembly, and the front windpiece assembly is provided with a front fixing frame 5, The rear wind panel assembly is provided with a rear fixing frame 8, the bracket 4, the front fixing frame 5, and the rear fixing frame are each provided with a threaded hole, and the front plate and the rear plate are connected together by a screw.

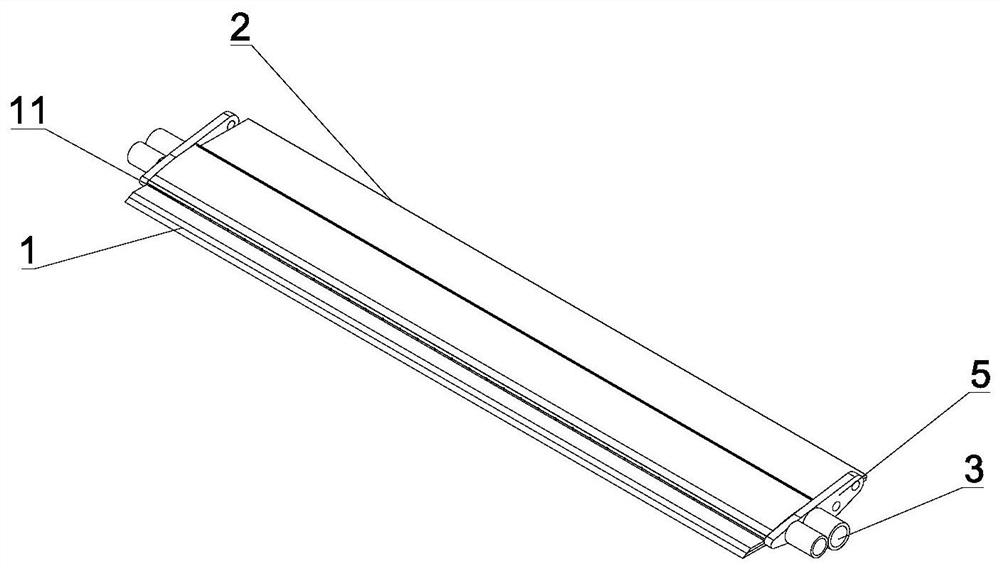

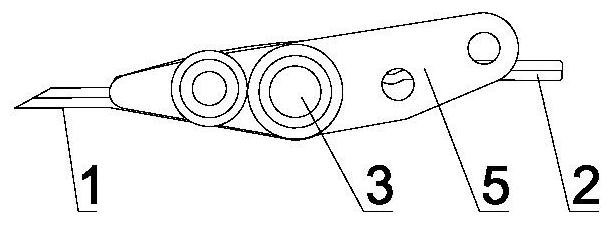

[0022]Such asFigure 1-3 As shown, the front wind panel assembly of the present invention is provided with a pair of front retracted frame 5, and the front retracted frame 5 is fixed to the front air pipe 3, and the front air pipe 3 is provided with a front blower shaped plate 1. The front blowing sheet 1 is a streamline structure. The front air tube 3 is provided in the inside of the front blowing shaped plate 1 forming a cavity, a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap