Sealing ring

A sealing ring and main body technology, which is applied to the sealing of the engine, engine components, mechanical equipment, etc., can solve the problems of reducing the cold water section of the vulcanized tube, affecting the sealing performance of the lower seal, and failing to achieve cooling, so as to improve work efficiency , Good sealing effect, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

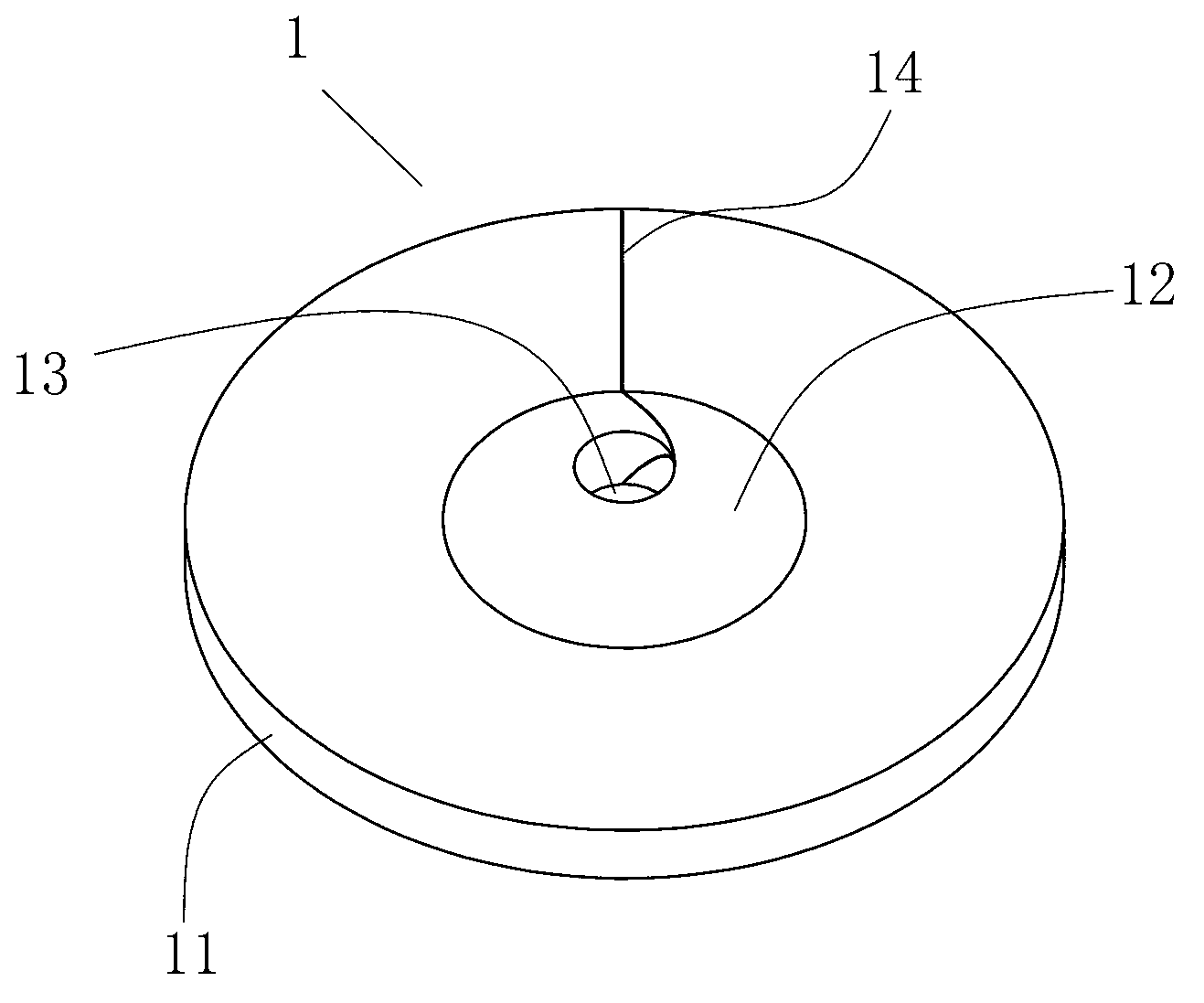

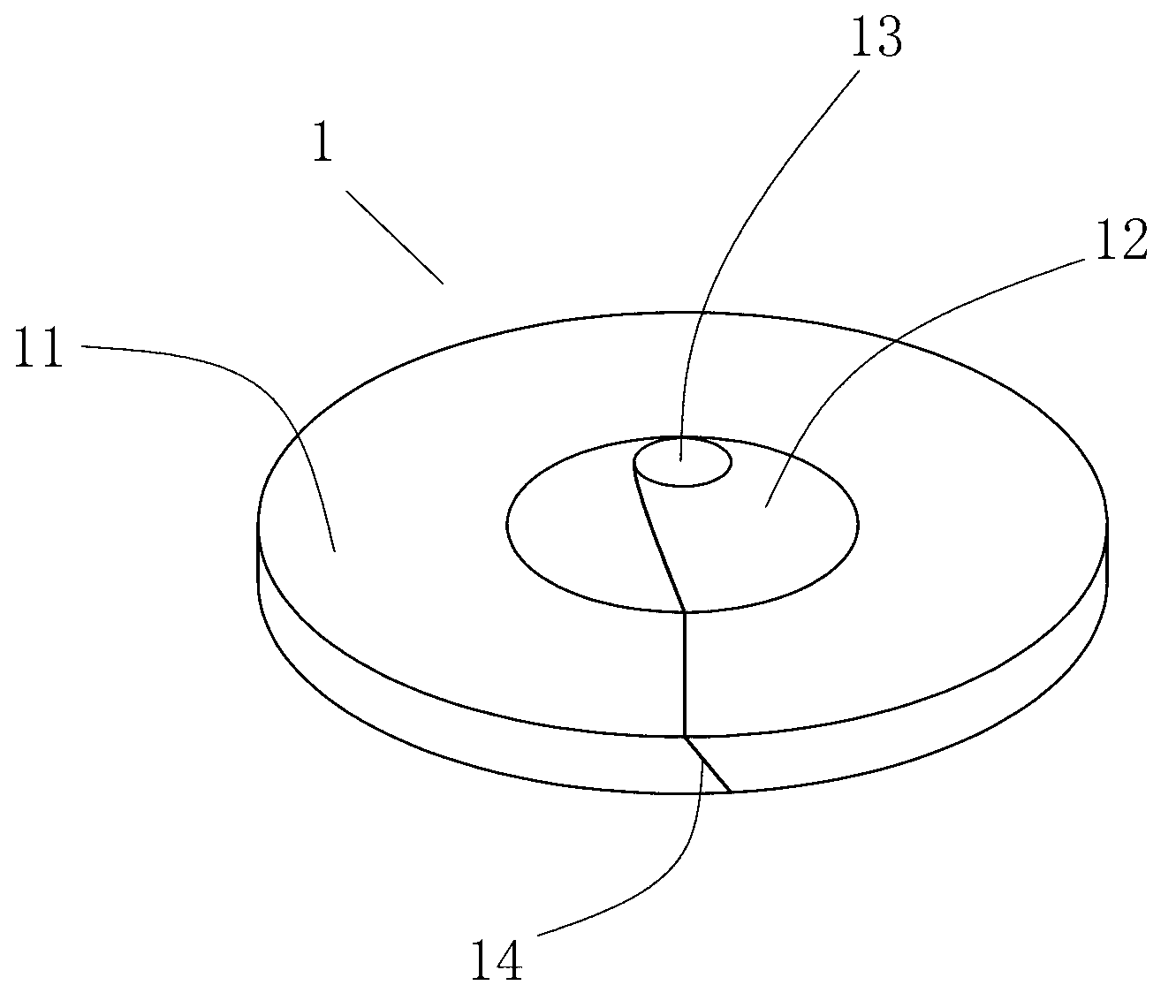

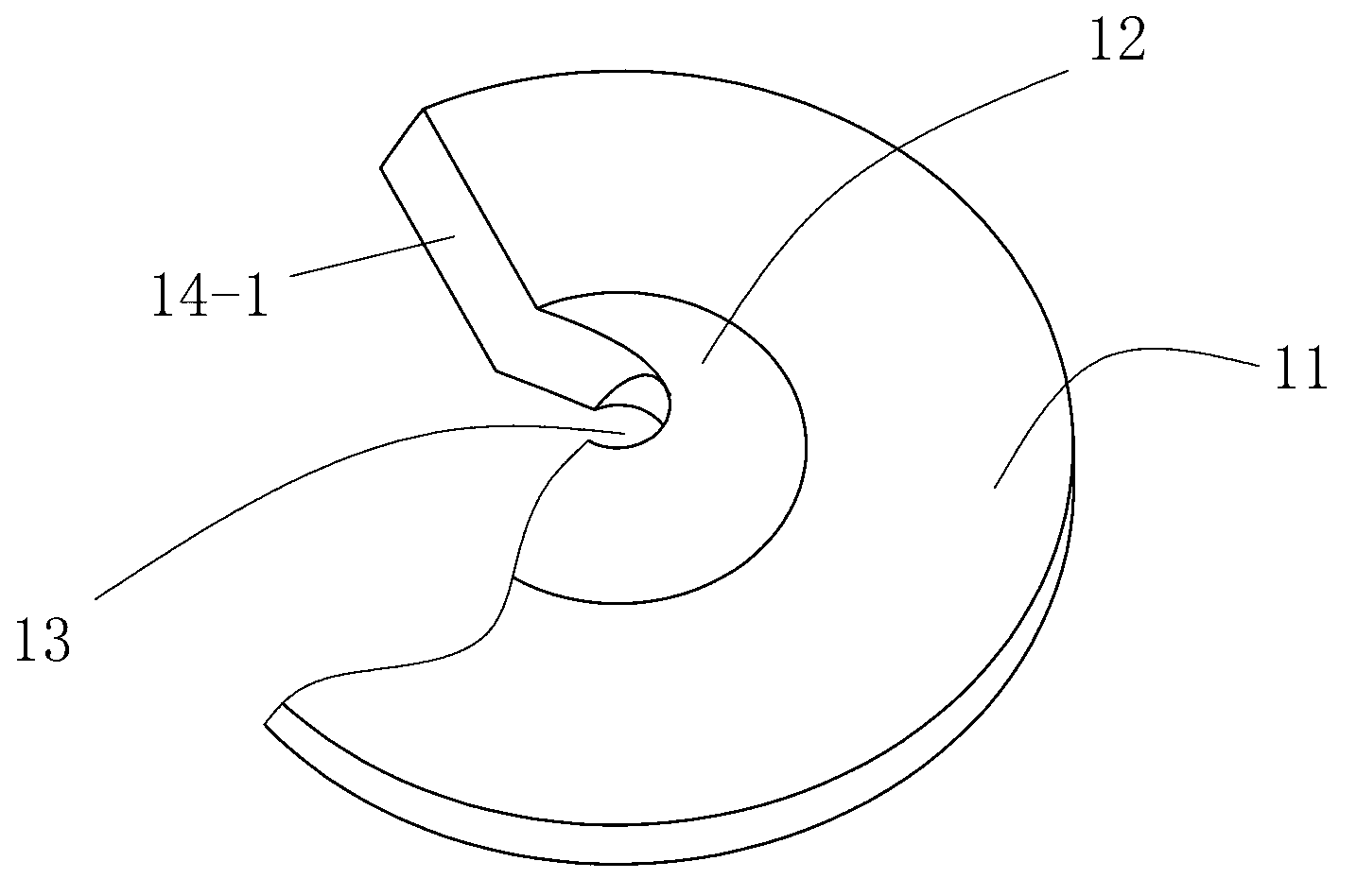

[0025] See figure 1 , figure 2 , Figure 5 and Figure 7 , The sealing ring 1 of the present invention is an integral piece of rubber. The sealing ring 1 includes a main body portion 11 and a protruding portion 12 . The main body 11 is in the shape of an annular plate as a whole, and the protruding portion 12 is in the shape of a conical shell as a whole. The protruding portion 12 is located at the center of the main body 11 , and is connected to the main body 11 from the inside, coaxial with the main body 11 , and the axis is the central axis 10 of the sealing ring 1 . The inner cavity of the frustum-shaped protruding portion 12 serves as an outlet hole 13 , which is also the central hole of the sealing ring 1 , and the axis of the central hole is also the central axis 10 of the sealing ring 1 .

[0026] See Figure 4 to Figure 7 , The outlet hole 13 includes a first hole segment 13-1 and a second hole segment 13-2 arranged coaxially in sequence from top to bottom. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com