Quickly-assembled steel reinforcement framework assembly in steel structure building exterior wall cladding

A technology for building exterior walls and steel skeletons, applied in building components, building reinforcements, buildings, etc., can solve the problems of wasting time and inconvenient disassembly and maintenance of steel skeletons, and achieve the effects of improving stability, rapid disassembly, and rapid disassembly and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

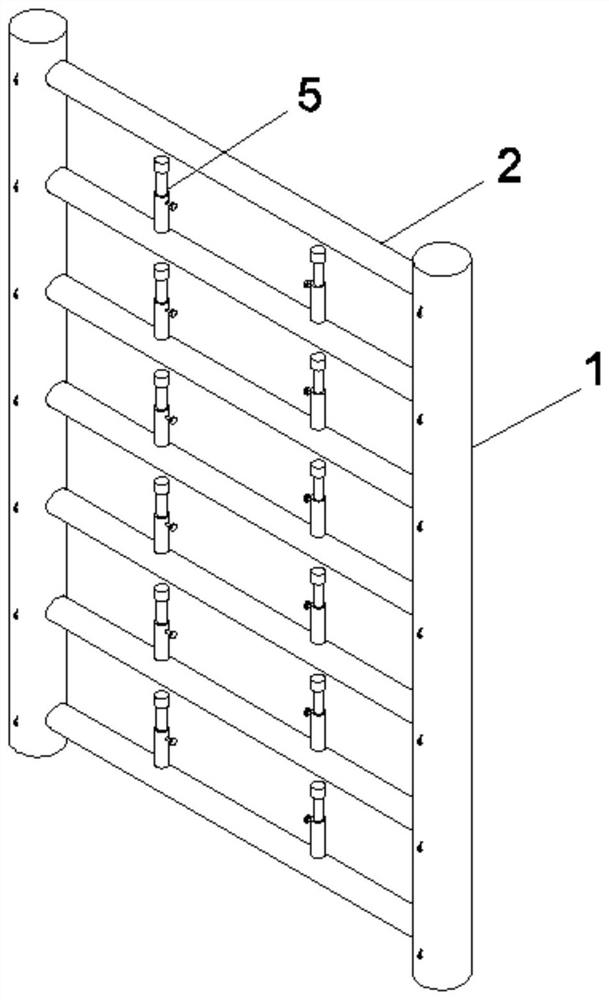

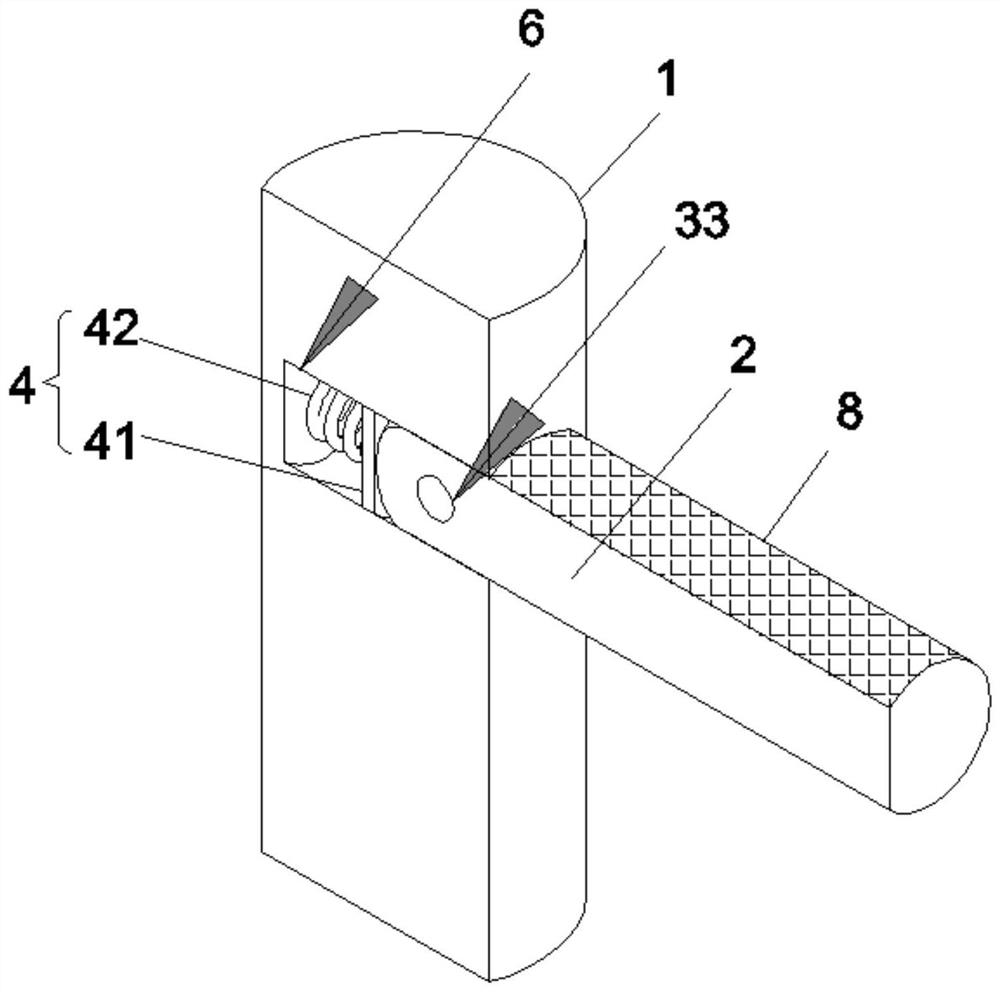

[0034]Such asFigure 1-4 As shown, the steel skeleton assembly in the outer wall of the steel structure building exterior wall is: first steel frame 1, second steel frame 2, pull mechanism 9, push mechanism 4 and support mechanism 5, first steel frame 1 The sidewall is opened on the side wall, and the second steel frame 2 is mounted on the side wall of the first steel frame 1 by the fixing mechanism 3, and the fixing mechanism 3 includes a fixing rod 31, a first spring 32, and a fixed hole. 33. The inside of the first steel frame 1 is opened with a slide 7 in communication with the fixed groove 6, and the fixing lever 31 is slidably coupled to the inside of the chute 7, and one end of the first spring 32 is located inside the chute 7 in the chute 7. One end is fixed, the other end of the first spring 32 is fixed to the inner wall of the chute 7, and the second steel frame 2 is opened to the sidewall of the second steel frame 2 having a fixing hole 33 mounted with the fixing lever 31....

Embodiment 2

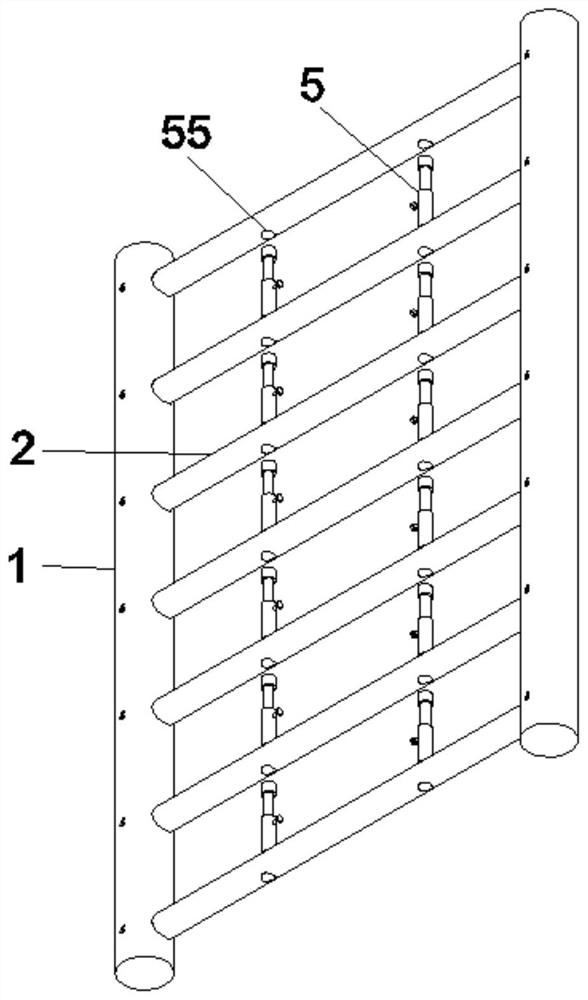

[0042]Such asFigure 5-9As shown, in order to further improve the assembly efficiency of the steel skeleton assembly, the support mechanism 5 unified standards are pre-installed in a reasonable position of the second steel frame 2, such as the welding or threaded connection, because the support mechanism 5 is pre-installed in the first On the two-steel frame 2, it is not necessary to remove it in the disassembly of the reinforced frame assembly. This embodiment does not repeatedly describe its specific installation mode, and no longer considers the pre-installed time problem, which is intended to solve the specific use of specific use. The problem of disassembly and assembly of the steel branches, in this embodiment, the support mechanism 5 specifically includes a support barrel 51, a support rod 52, a pinch device 53, and a wire block 55 is fixed under the support barrel 51, and the iron block 55 and the supportor. The interior of the 51 terminal constitutes the card slot 56, the ir...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap