Device and method for fixing drain pipe in nuclear power steam generator

A technology of steam generator and fixing device, applied in nuclear power generation, steam trap, reduction of greenhouse gases, etc., can solve the problem that the drain pipe cannot be introduced from the bottom side of the separator according to the original process, affects the accuracy of the docking position, and slides down with its own weight, etc. problems, to reduce the steps of installing lifting points, simplify the installation process, and achieve the effect of strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be further described in detail through the drawings and examples below. Through these descriptions, the features and advantages of the present invention will become more apparent.

[0073] The word "exemplary" is used exclusively herein to mean "serving as an example, embodiment, or illustration." Any embodiment described herein as "exemplary" is not necessarily to be construed as superior or better than other embodiments. While various aspects of the embodiments are shown in drawings, the drawings are not necessarily drawn to scale unless specifically indicated.

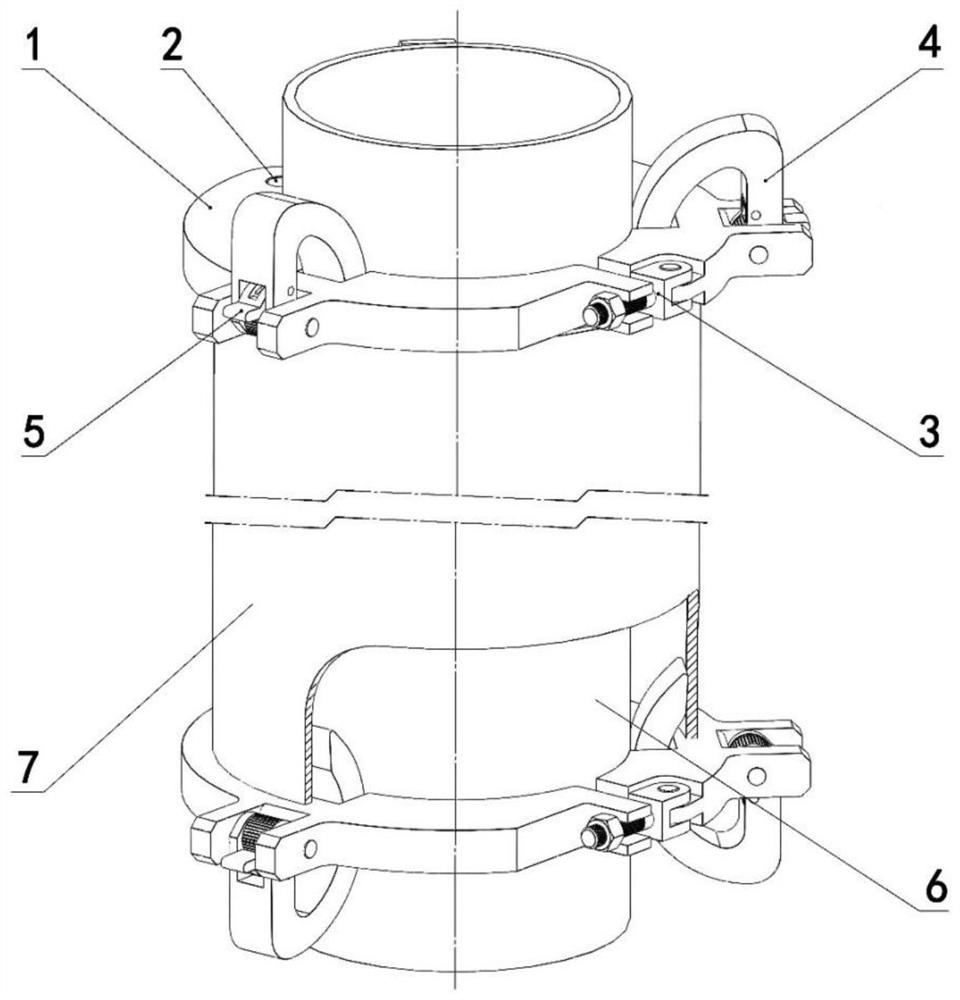

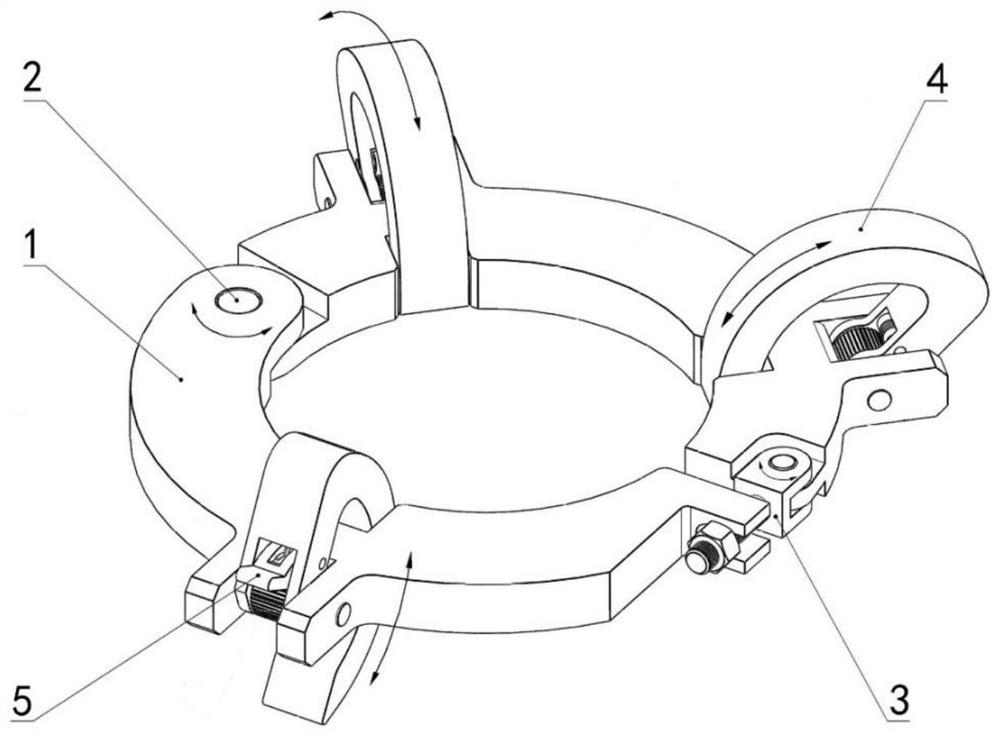

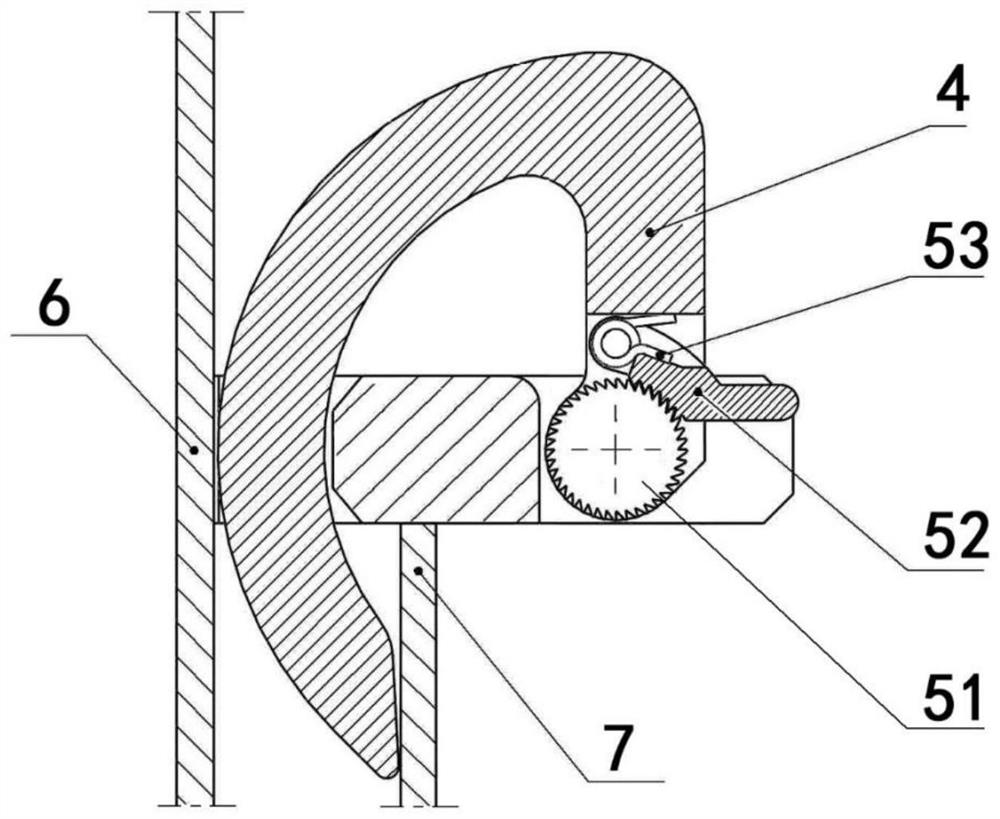

[0074] According to a kind of nuclear power steam generator internal drainage pipe fixing device provided by the present invention, such as figure 1 As shown, the fixing device includes a ring plate 1, a connecting shaft 2, a locking bolt 3, a hook plate 4 and a ratchet assembly 5, such as figure 1 shown;

[0075] The ring plates 1 are in multiple groups, each group of ring plat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap