Road surface flatness measuring device

A technology for measuring devices and road surfaces, which is applied in the directions of measuring devices, roads, roads, etc., can solve the problems of vibration of the measuring device, affecting the measurement accuracy, and reducing the detection accuracy of the measuring instrument.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

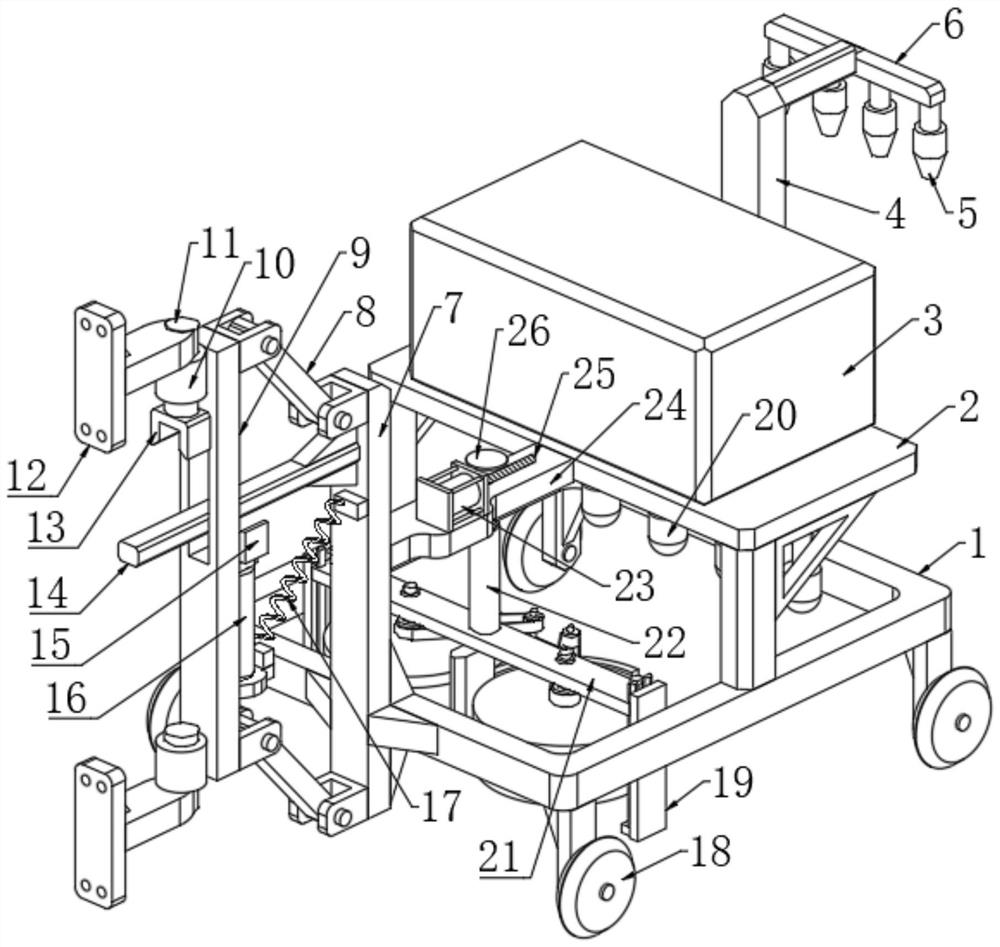

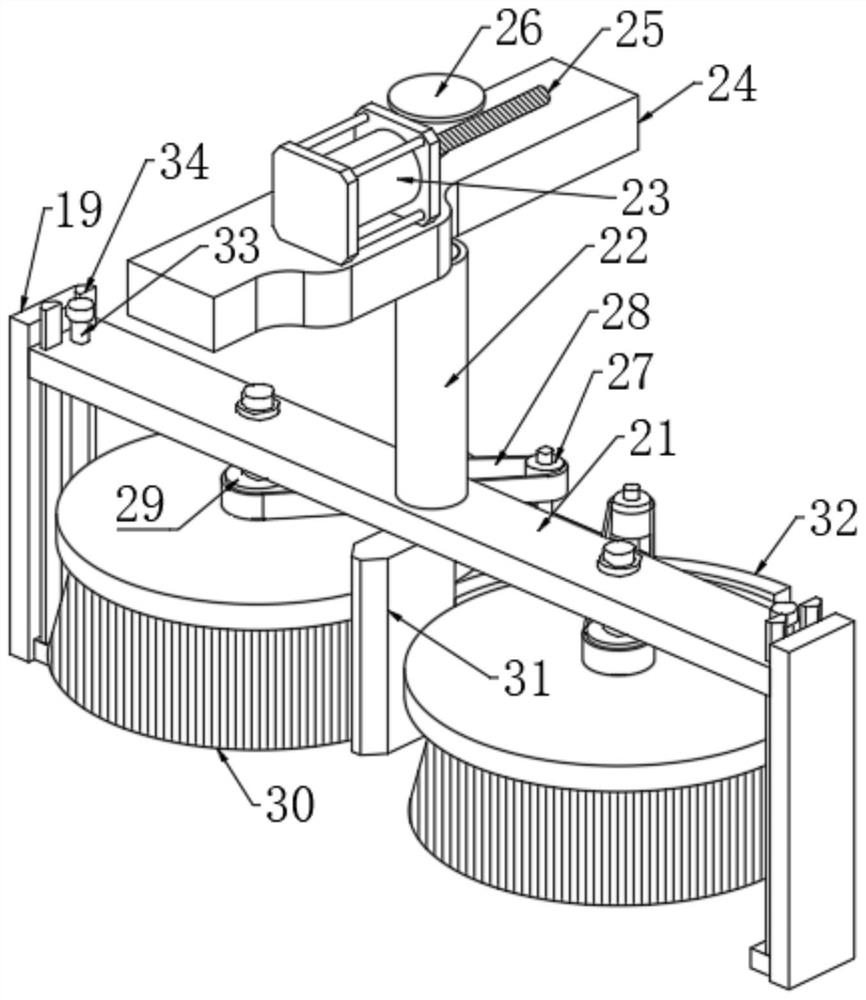

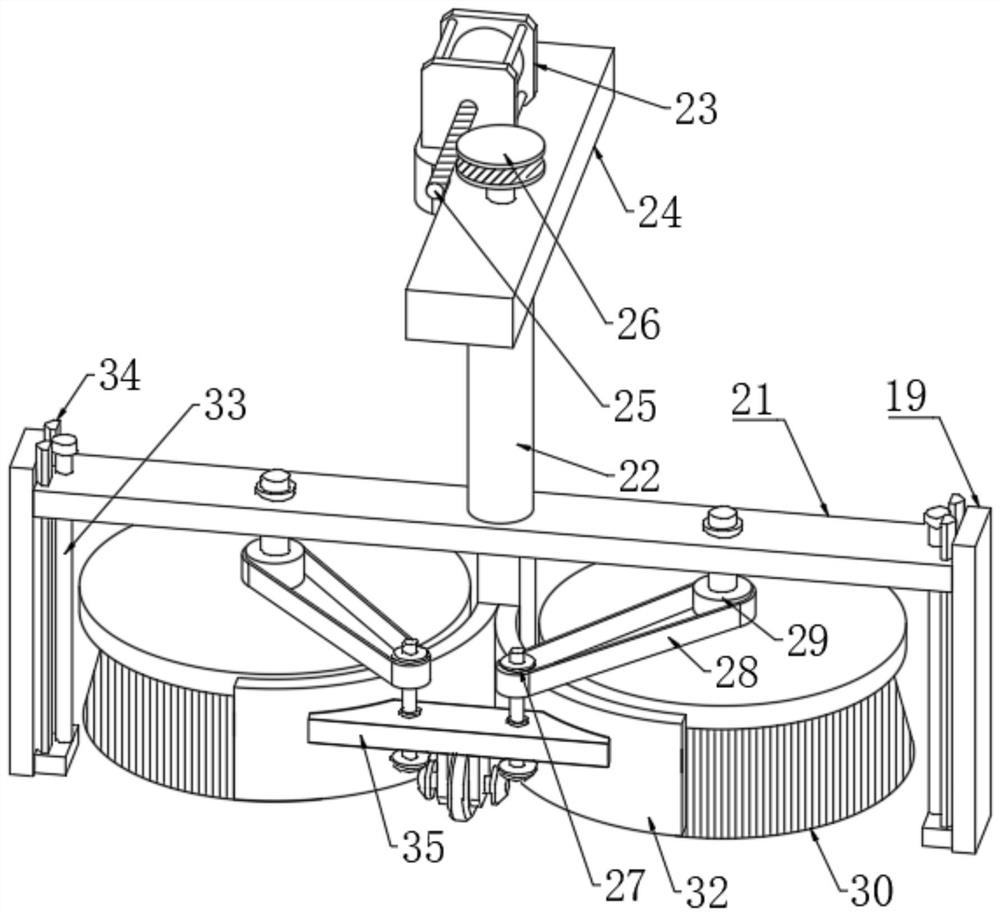

[0028] A road surface smoothness measurement device, comprising a detection host 3, a plurality of infrared sensors 5, a plurality of displacement sensors 20 and a rectangular frame 1, two vertical poles are fixedly connected to the upper edge of the rectangular frame 1, and the two vertical poles The upper end of the horizontal plate 2 is fixedly connected with the horizontal plate 2, the upper end of the horizontal plate 2 is fixedly connected with the lower end of the detection host 3, the lower end of the horizontal plate 2 is fixedly connected with a plurality of displacement sensors 20, and the center of the upper rear edge of the rectangular frame 1 is fixedly connected There is a support rod 4, the upper side of the rear end of the support rod 4 is fixedly connected with a fixed frame 6, the side wall of the fixed frame 6 is fixedly connected with a plurality of infrared sensors 5, and the inner side of the rectangular frame 1 is symmetrically fixedly connected with two ...

Embodiment 2

[0030] Embodiment 2: the difference based on Embodiment 1 is;

[0031] The cleaning mechanism includes two arc-shaped plates 32 symmetrically fixed on the rear end of the mounting block 31, the rear sides of the two arc-shaped plates 32 are jointly fixedly connected with a connecting block 35, and the lower end of the connecting block 35 is fixedly connected with two fixed blocks, two Between the fixed blocks, a rotating shaft is jointly rotated through the first rolling bearing, and a transmission wheel 39 is fixedly connected to the shaft wall of the rotating shaft. Both ends of the rotating shaft pass through the first rolling bearing and are fixedly connected to the first bevel gear 40. The lower end is connected with two support shafts through the second rolling bearing, the lower ends of the two support shafts are fixedly connected with the second bevel gear 41, the first bevel gear 40 meshes with the second bevel gear 41, and the upper end of the support shaft passes thr...

Embodiment 3

[0033] Embodiment 3: the difference based on embodiment 1 is;

[0034] The traction mechanism includes a brake plate 9 parallel to the front side of the support plate 7, and the opposite side of the brake plate 9 and the support plate 7 is connected with two obliquely arranged pull rods 8 through pin rotation, and the two pull rods 8 are parallel to each other. The front end of the brake plate 9 is symmetrically fixedly connected with two sliding sleeves 10, and the two sliding sleeves 10 are rotatably connected with a connecting shaft 11 through a sealed bearing, and the lower end of one of the connecting shafts 11 passes through the sealed bearing and is fixedly connected with an inverted shaft. U-shaped block 13, the shaft wall of the connecting shaft 11 is fixedly connected with an inverted T-shaped connector 12, the side wall of the vertical part of the T-shaped connector 12 is provided with a plurality of assembly holes, and the side wall of the brake plate 9 passes throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com