Method for predicting working hours of airplane structural part processing procedure

A technology for aircraft structural parts and processing procedures, applied in the field of aircraft structural parts, can solve problems such as unreasonable production planning, low efficiency, and low accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

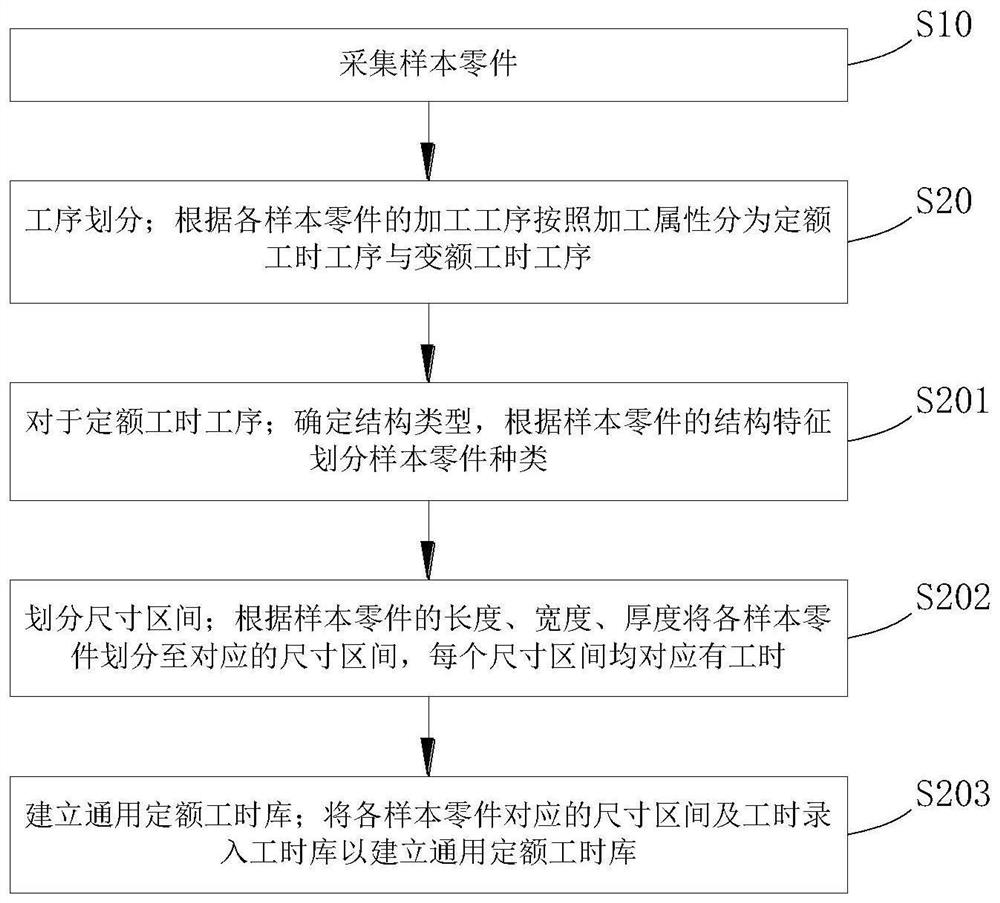

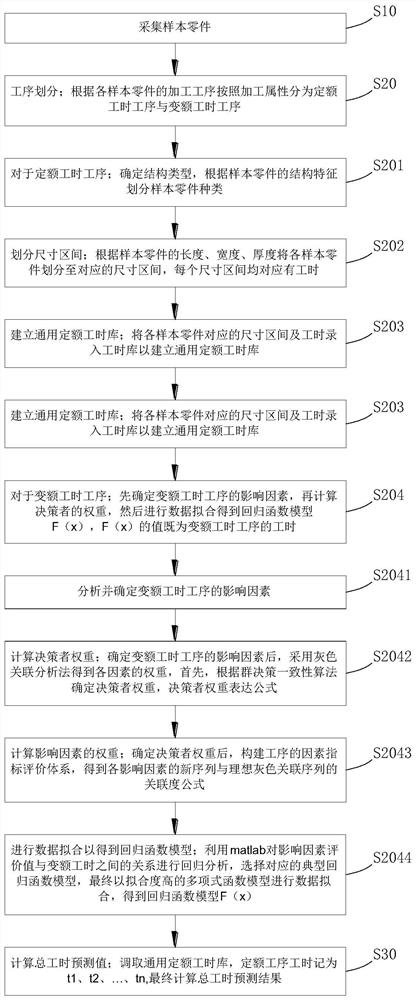

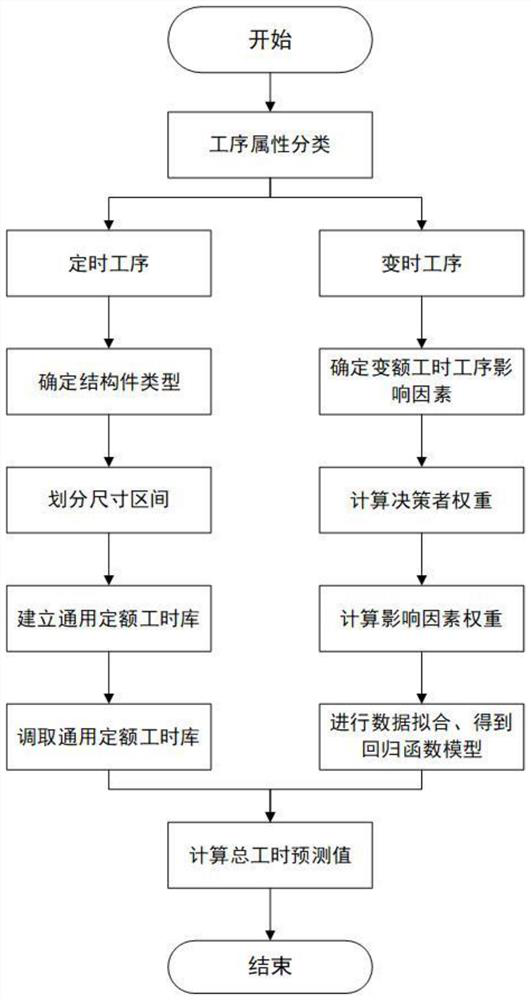

[0054] Please refer to Figure 1-3 , the present embodiment provides a man-hour prediction method for the machining process of aircraft structural parts, comprising the following steps:

[0055] S10: collecting sample parts.

[0056] Exemplarily, collect sample data of working hours of each process of parts of different sizes and types, and filter out the data samples of parts with countless models, incomplete process information, and abnormal working hours to obtain sample parts; Complete and abnormal part data samples are used to obtain sample parts. Such sample parts are fully representative and improve the accuracy of analysis results.

[0057] S20: process division; according to the processing process of each sample part, it is divided into a fixed man-hour process and a variable man-hour process according to the processing attributes.

[0058] The characteristic of the fixed working hours process is that it is less affected by the nature of the parts themselves, such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com