System and method for temperature control of electronic equipments

A technology of temperature control and electronic equipment, which is applied in the direction of temperature control using electric methods, can solve the problems of complex, inaccurate reaction temperature, and high cost, and achieve convenient maintenance and management, low engineering cost, and stable and reliable results. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

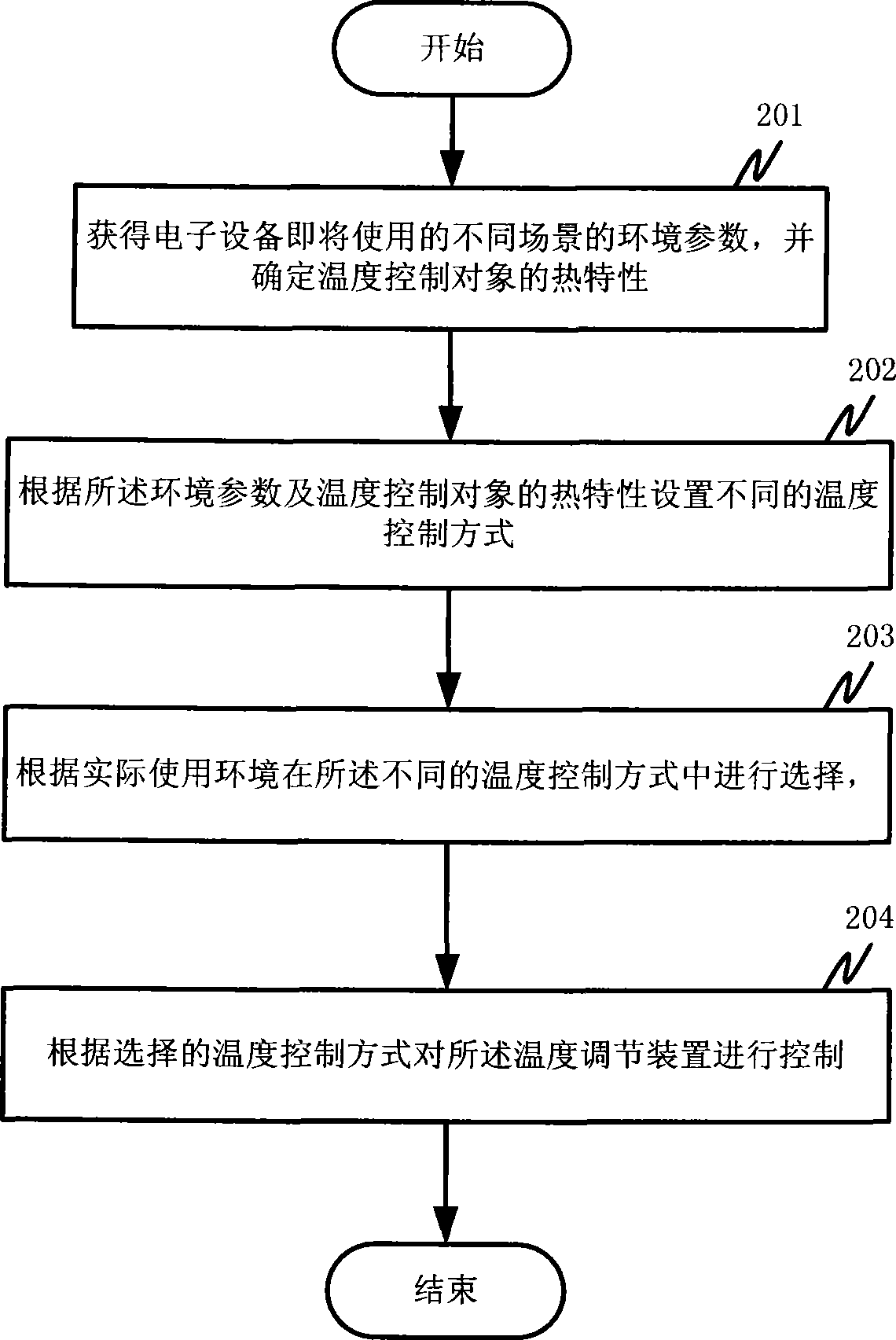

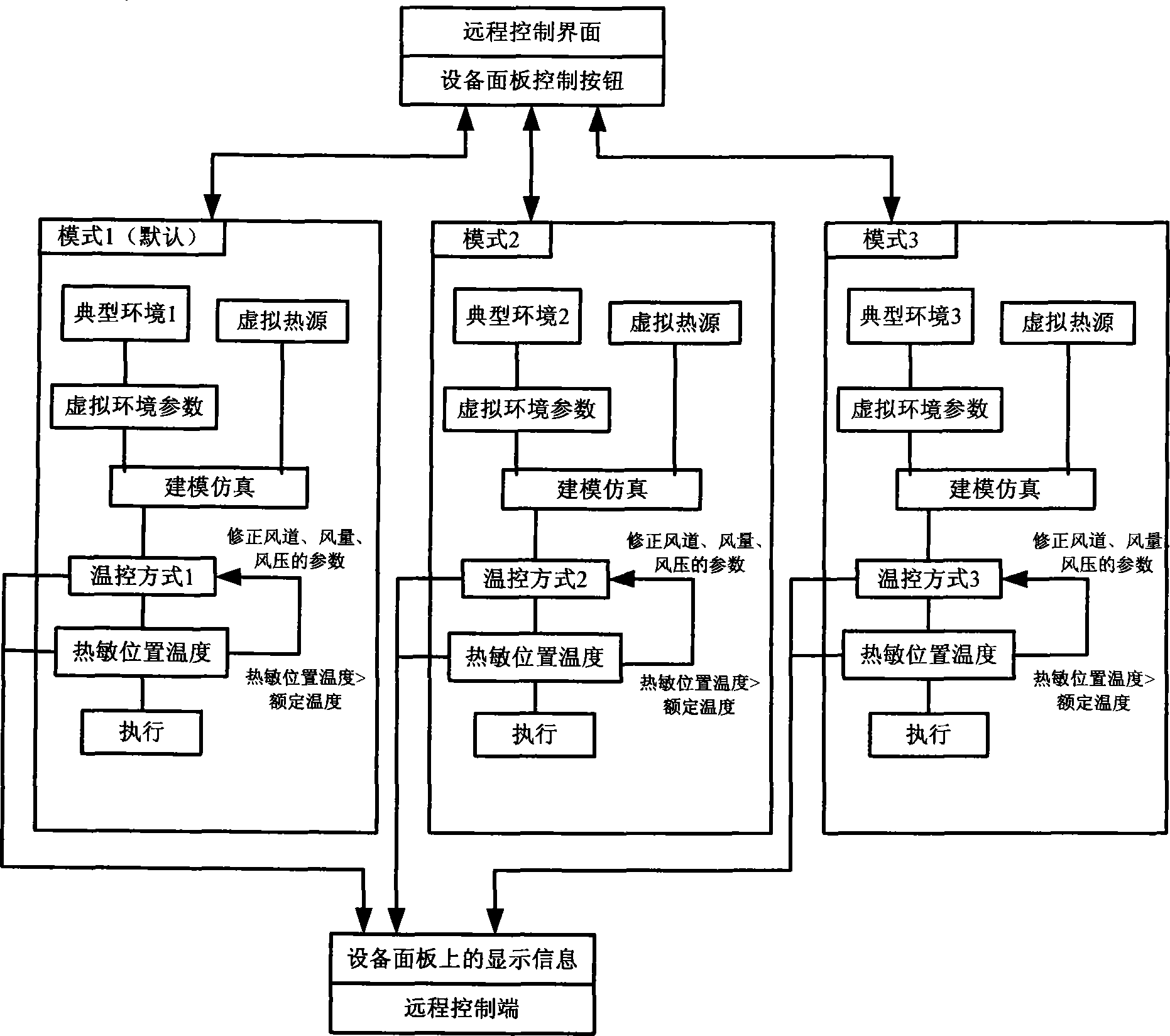

[0047] According to the environmental parameters of the environment where the electronic equipment may be used, and in combination with the characteristics of the temperature control object (that is, the components that need to be temperature-controlled in the electronic equipment), the present invention sets the temperature control methods for the electronic equipment in different use environments, and can be based on According to the needs of the actual environment, use the automatic mode or manual mode to select the temperature control mode.

[0048] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

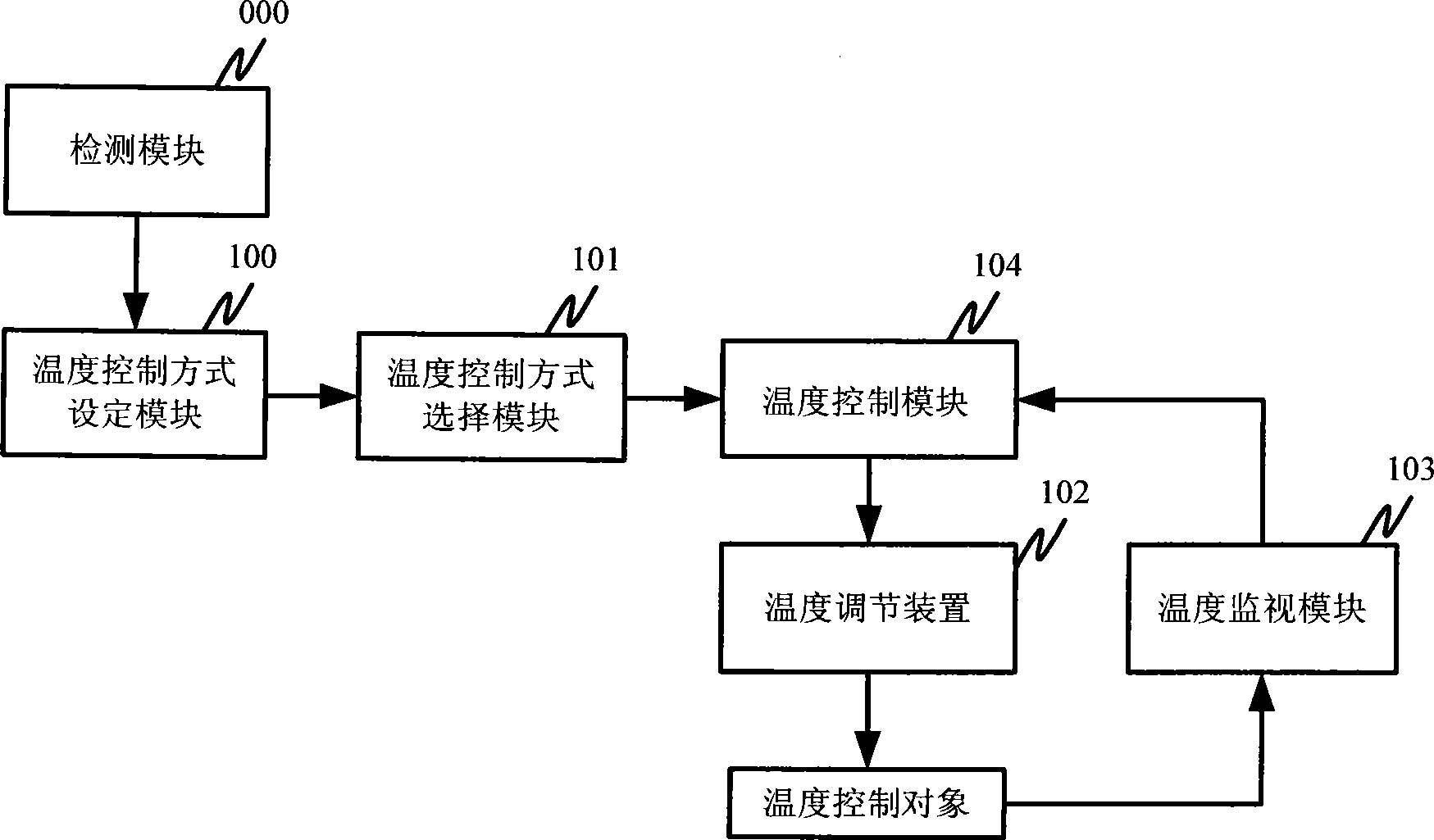

[0049] refer to figure 1 As shown, it is a schematic structural diagram of the system for controlling the temperature of electronic equipment according to the present invention. The system includes: a detection module 000 , a temperature control mode setting module 100 , a temperature control mode s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com