Visual model structure convenient for high-pressure cyclic heating

A model structure, high-pressure circulation technology, applied in teaching models, wellbore/well components, instruments, etc., can solve the problems of difficult to blow off the gas structure, difficult to disassemble, damage to the spacer glass, etc., to achieve simple and fast operation and increase convenience sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

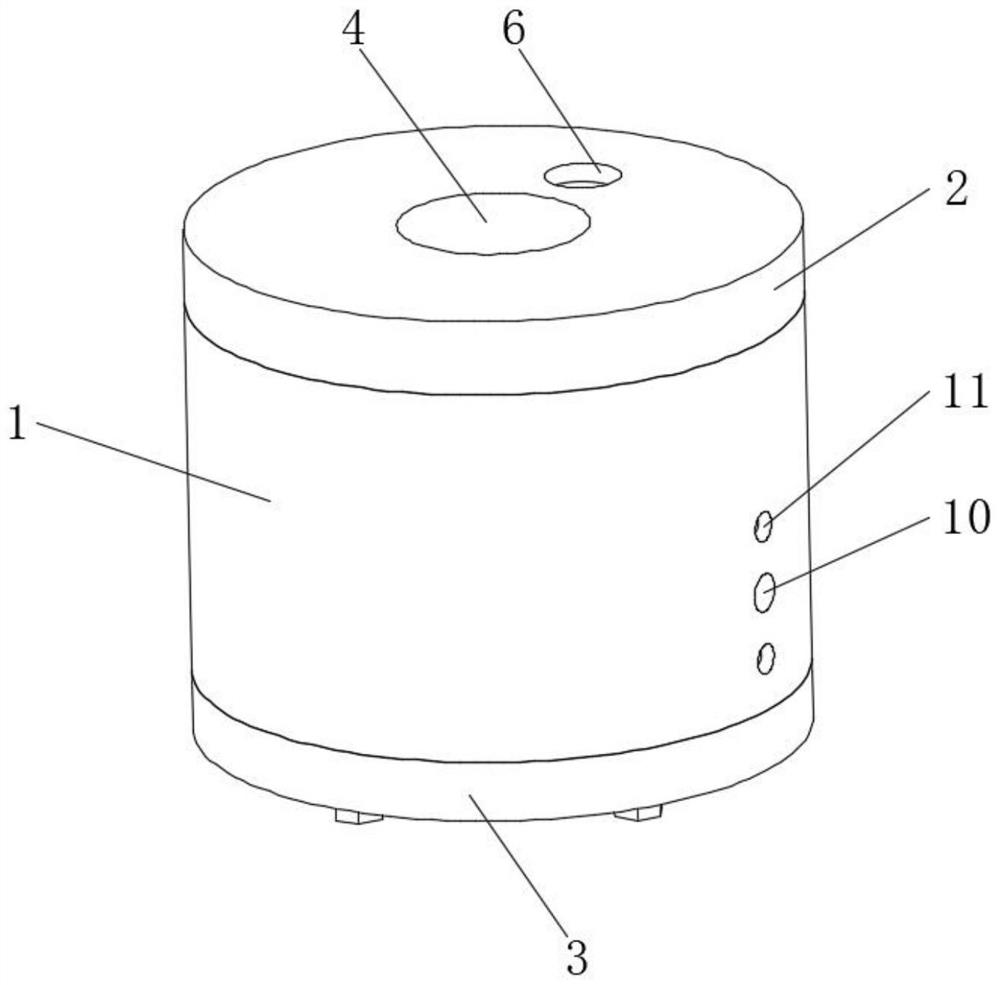

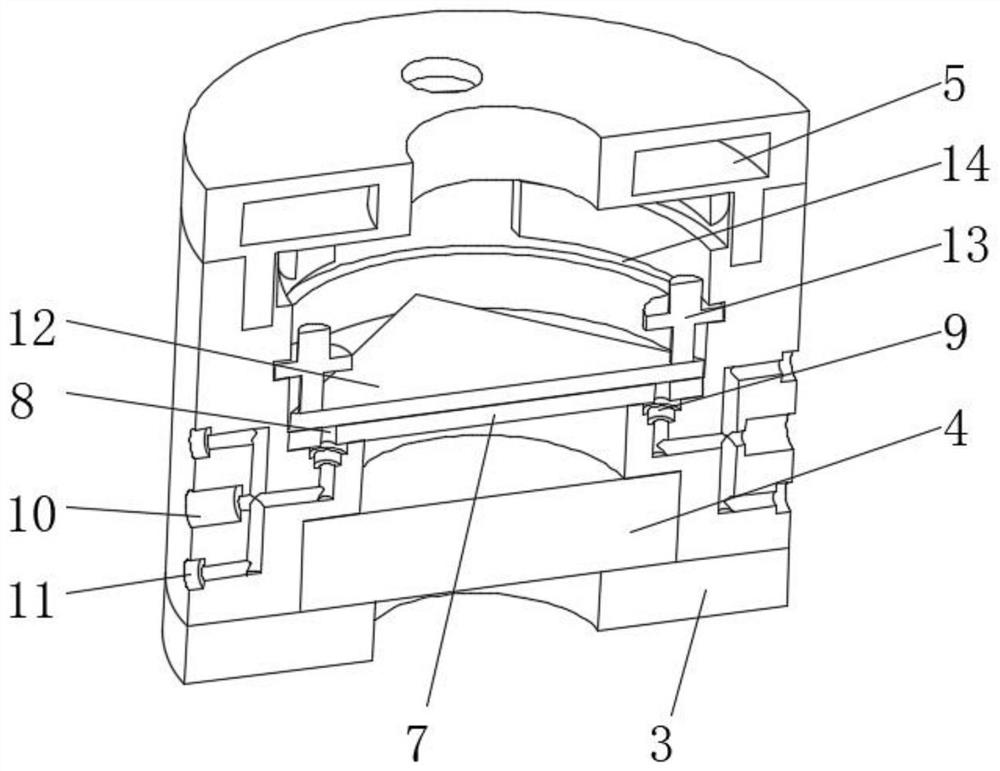

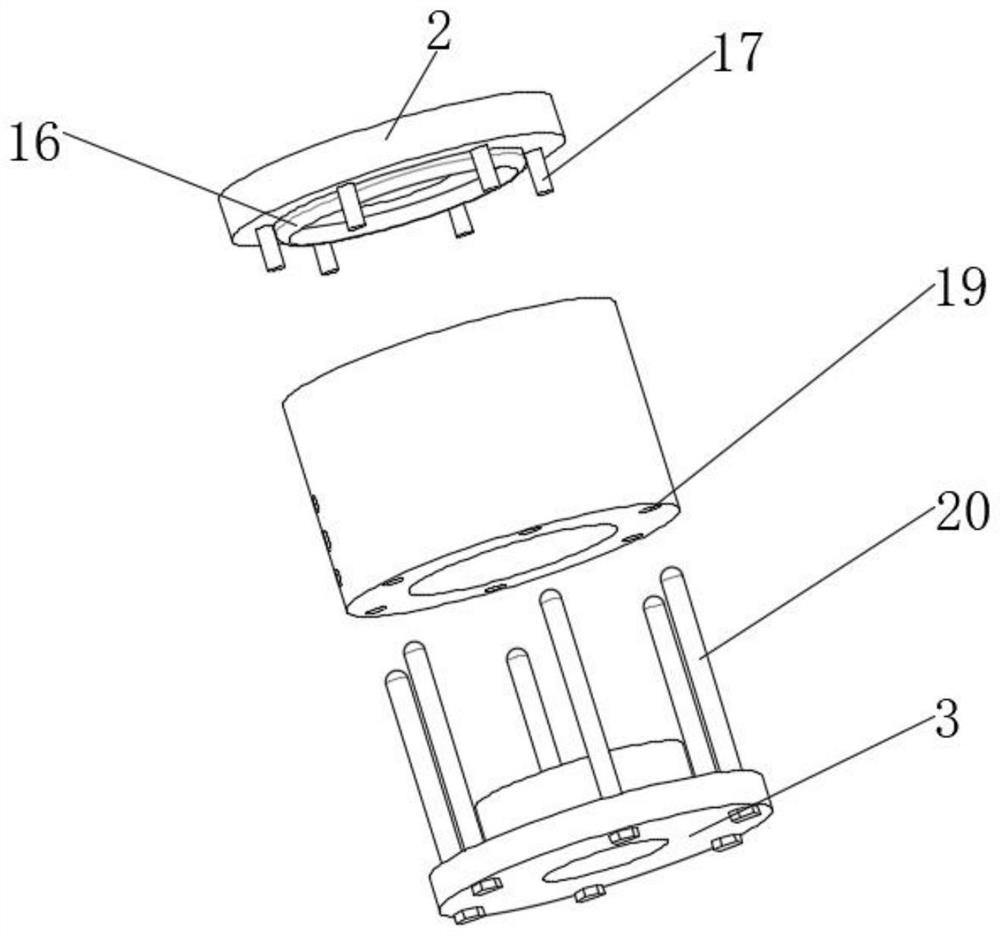

[0023] see Figure 1-4 , a visual model structure convenient for high-pressure cycle heating, including a kettle body 1, the top of the kettle body 1 is provided with an upper kettle cover 2, the lower surface of the kettle body 1 is fixedly connected with several limit bolts 17, and the bottom of the kettle body 1 A glass pressure plate 3 is provided at the end, and a bolt 20 is connected to the glass pressure plate 3. A lower spacer glass 7 is placed in the kettle body 1. An upper spacer glass 12 is arranged above the lower spacer glass 7. The lower spacer glass 7 Both sides of the surface are provided with through holes 8, the inner wall surface of the kettle body 1 is provided with a circular groove 9, the surface of the kettle body 1 is provided with an input port 10, and the input port 10 and the circular groove 9 are connected by a through groove, and the input port 10 The upper and lower sides of the upper and lower sides are provided with outlets 11, the outlets 11 co...

Embodiment 2

[0025] Based on Example 1, such as Figure 1-4 , both sides of the upper surface of the upper spacer glass 12 are fixedly connected with the limiter 13, the inner wall surface of the kettle body 1 is provided with a limiter ring groove 14, the limiter 13 is snapped with the limiter ring groove 14, and the limiter ring groove 14 There are installation notches 15 on one side of the wall, and the number of installation notches 15 is two. Insert the upper spacer glass 12 upper limit member 13 from the installation notch 15 into the limit ring groove 14, and rotate the upper spacer glass 12 The limiting member 13 is engaged with the limiting ring groove 14 to complete the fixing of the limiting member 13 and install the upper spacer glass 12 .

[0026] Working principle: When using the pump device, insert the limit bolt 17 into the limit hole 18 to complete the installation of the upper kettle cover 2, and the sealing ring 16 on the lower surface of the upper kettle cover 2 ensures...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com