Environment-friendly semi-automatic rotary washing machine for rotating shuttles

A semi-automatic and environment-friendly technology, applied in the direction of cleaning hollow objects, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of high labor intensity, low efficiency, and non-environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] Before describing this embodiment in detail, in order to understand the device more clearly, the rotary hook is briefly described below.

[0036] Such as Figure 8 As shown, the existing rotary hook a is mainly composed of an outer shuttle a2, an inner shuttle a1, and a moon circle a3; The present embodiment is described below:

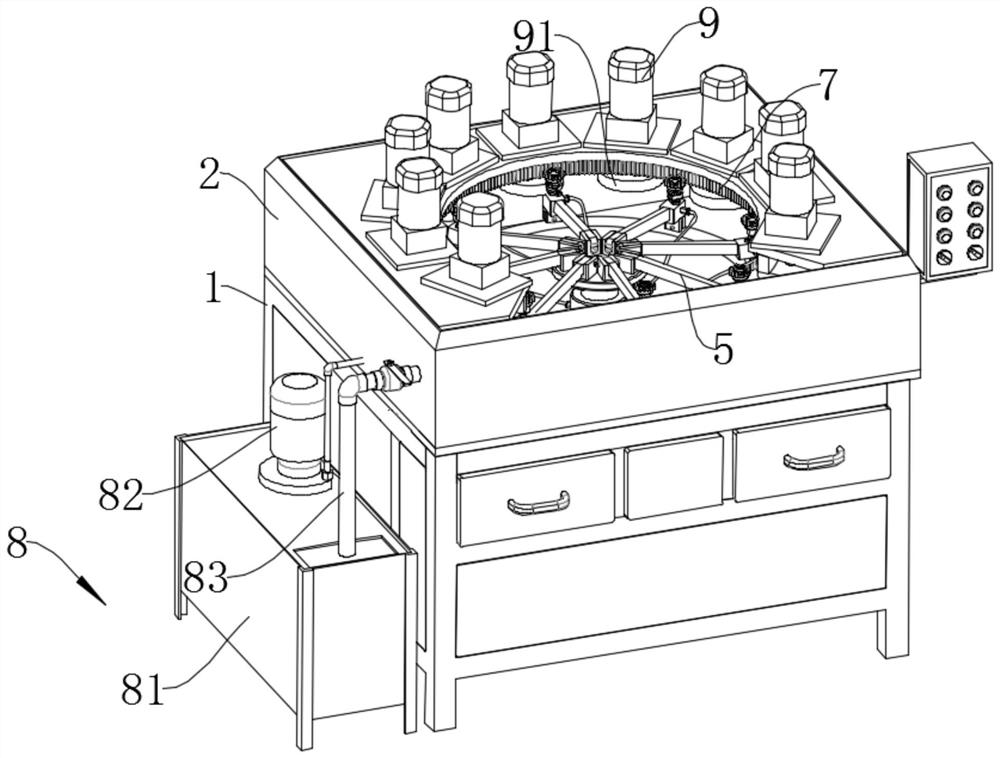

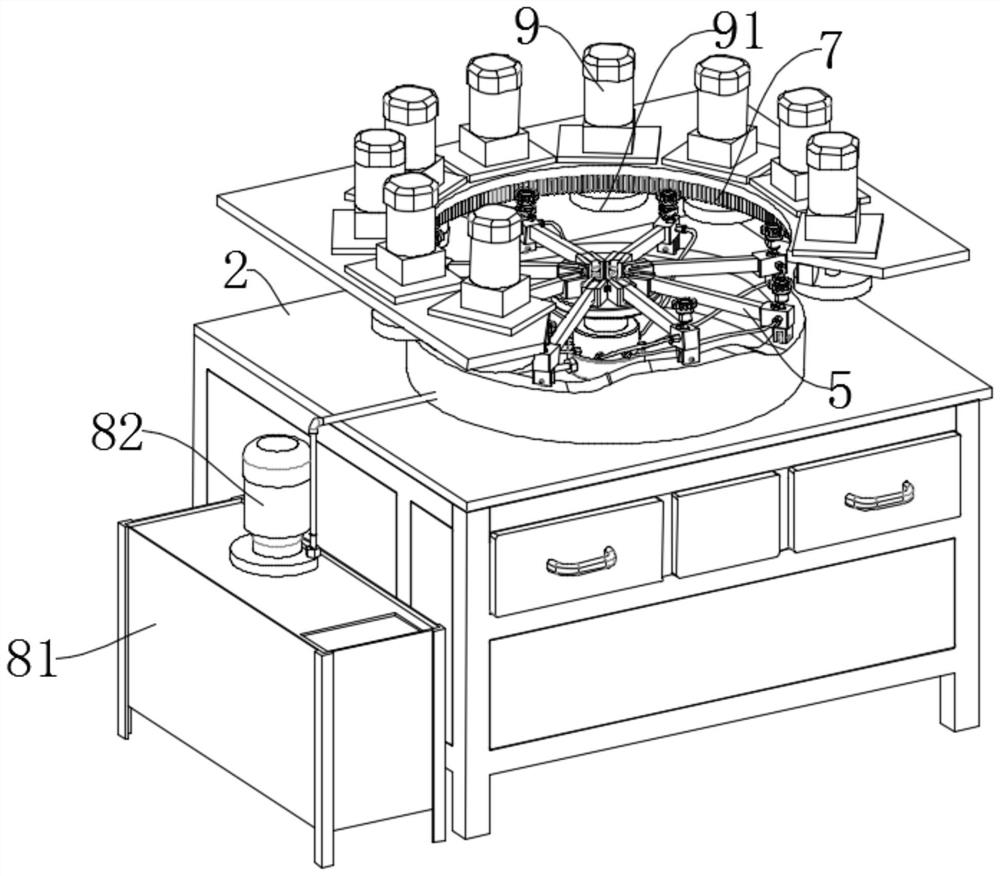

[0037] refer to figure 1 As shown, this embodiment provides an environment-friendly semi-automatic rotary washing machine for rotary hook a, which includes a main body support 1 and an oil pool 2 arranged on the upper part of the main body support 1; the oil pool 2 is mainly used to store the oil for cleaning the rotary hook a; During cleaning, the rotary hook a is immersed in the oil in the oil pool 2. An opening is formed on the top of the oil pool 2, through which the hook a can be loaded and unloaded.

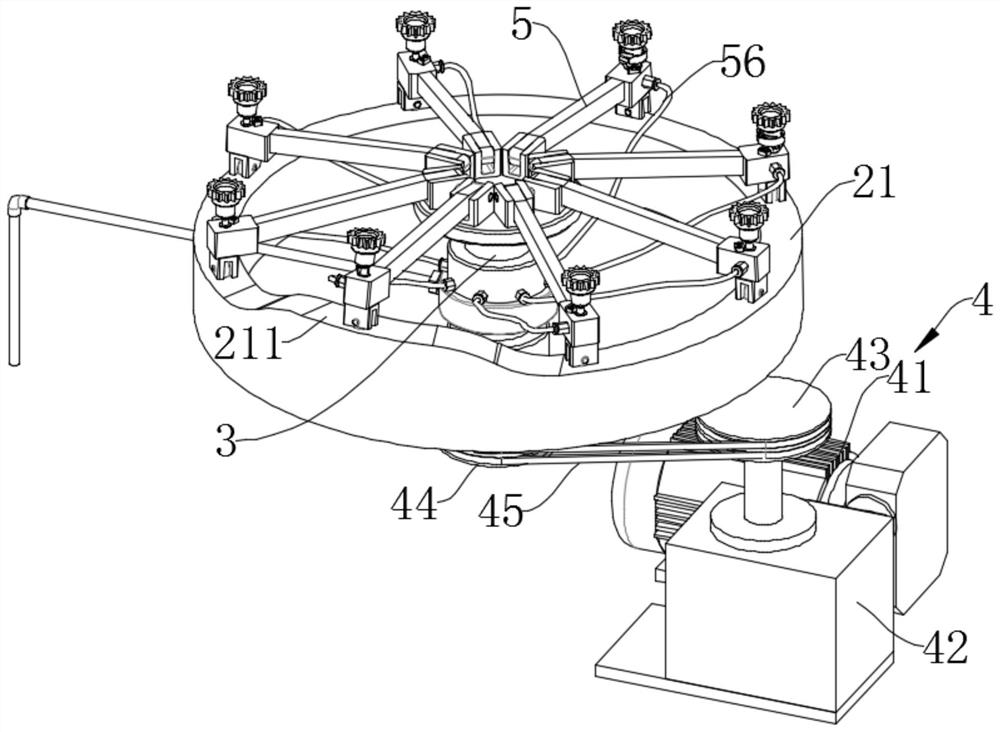

[0038] combine image 3 As shown, the oil pool 2 is provided with a rotating shaft 3; the rotating shaft 3 is provided with at least o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com