A method for machining shallow grooves on retaining rings

A processing method and shallow groove technology, applied in the field of parts processing, can solve the problems of poor openness, the surface roughness of shallow grooves is difficult to reach Ra3.2, and the processing efficiency of shallow grooves is reduced, so as to avoid secondary grinding and improve processing. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

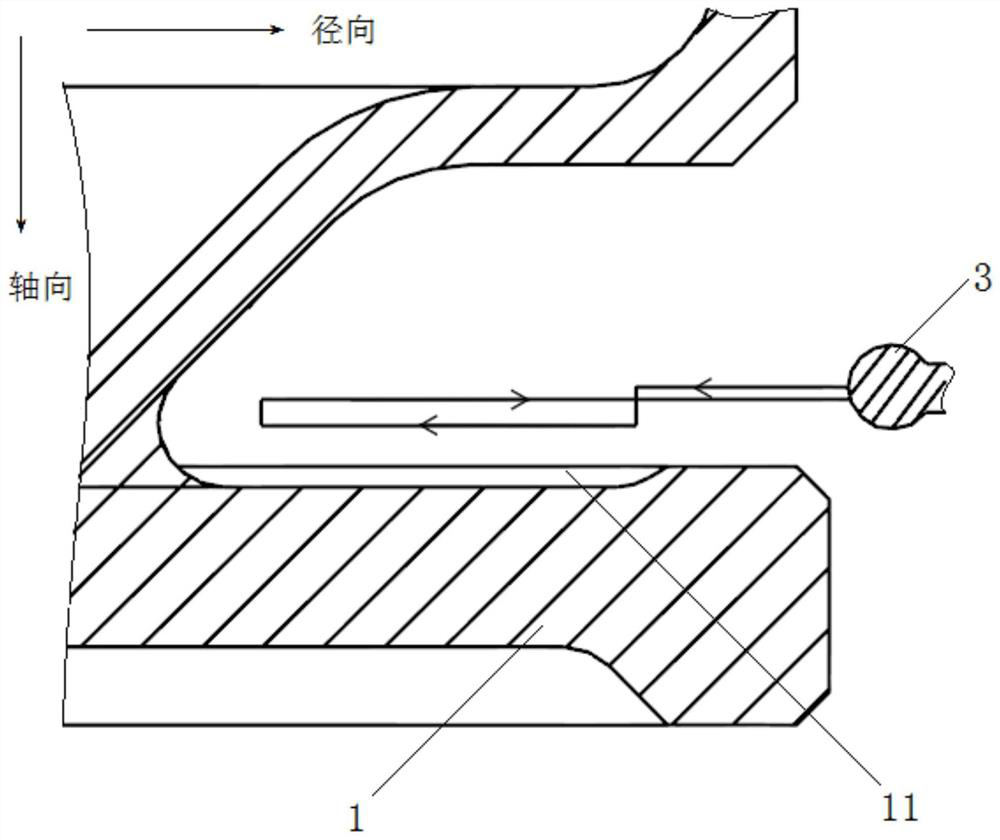

[0032] The invention relates to a processing method for a shallow groove on a retaining ring. The steps include the following:

[0033] Step 1: The retaining ring 1 is fixed on the rotating shaft of the lathe, the round head turning tool 3 is fixed on the tool, and the round head turning tool 3 is aligned with the outer end of the shallow groove to be processed;

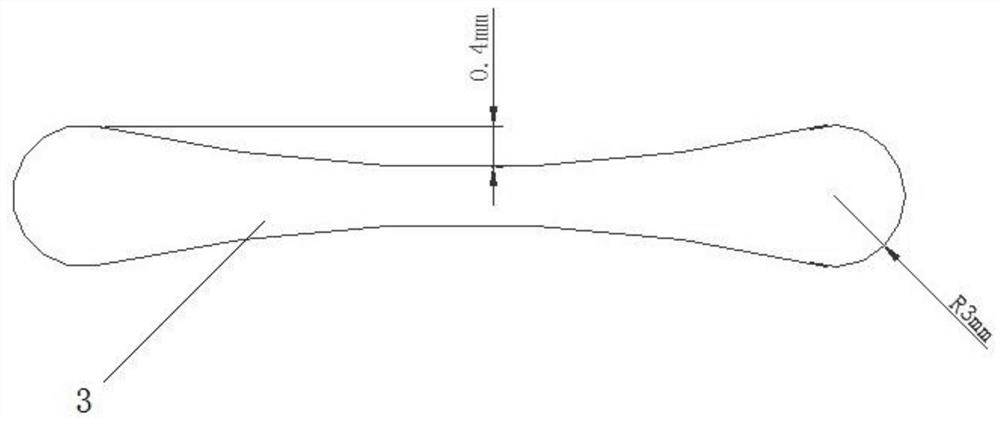

[0034] Step 2: The retaining ring 1 rotates at a speed of 33r / min on the axial center line. If the speed is too fast, the tool wears quickly, and the surface of the tool is prone to local thermal hardening, which affects the quality of the machined surface, and the low speed reduces the production efficiency; The round head of the knife 3 is axially approaching the shallow groove, and the amount of the close back knife is 0.2mm. The knife is manually polished with a polishing wheel to grind the side of the ball-end blade, and the blade has poor rigidity. This cutting amount; the 0.4mm unilateral clearance on the rou...

Embodiment 2

[0037] The invention relates to a processing method for a shallow groove on a retaining ring. The steps include the following:

[0038] Step 1: The retaining ring 1 is fixed on the rotating shaft of the lathe, the round head turning tool 3 is fixed on the tool, and the round head turning tool 3 is aligned with the outer end of the shallow groove to be processed;

[0039] Step 2: The retaining ring 1 rotates at a speed of 32r / min on the axial centerline. If the speed is too fast, the tool wears quickly, and the surface of the tool is easy to form local thermal hardening, which affects the quality of the machined surface. Low speed reduces production efficiency; The round head of the knife 3 is axially approaching the shallow groove, and the amount of the close knife is 0.16mm. The knife is manually polished with a polishing grinding wheel to grind the side of the ball-end blade. The rigidity of the blade is poor. This cutting amount; the 0.4mm unilateral clearance on the round...

Embodiment 3

[0042] The invention relates to a processing method for a shallow groove on a retaining ring. The steps include the following:

[0043] Step 1: The retaining ring 1 is fixed on the rotating shaft of the lathe, the round head turning tool 3 is fixed on the tool, and the round head turning tool 3 is aligned with the outer end of the shallow groove to be processed;

[0044] Step 2: The retaining ring 1 rotates at a speed of 45r / min on the axial centerline. If the speed is too fast, the tool wears quickly, and the surface of the tool is prone to local thermal hardening, which affects the quality of the machined surface, and the low speed reduces the production efficiency; The round head of the knife 3 is axially approaching the shallow groove, and the amount of the close back knife is 0.1mm. The knife is manually polished with a polishing grinding wheel to grind the side of the ball-end blade. The rigidity of the blade is poor. This cutting amount; the 0.4mm unilateral gap on the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap