Clamping device for intelligent furniture production

A clamping device and smart furniture technology, applied in the direction of workpiece clamping devices, manufacturing tools, etc., can solve the problems of furniture surface paint damage, clamping damage, and increased labor intensity of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

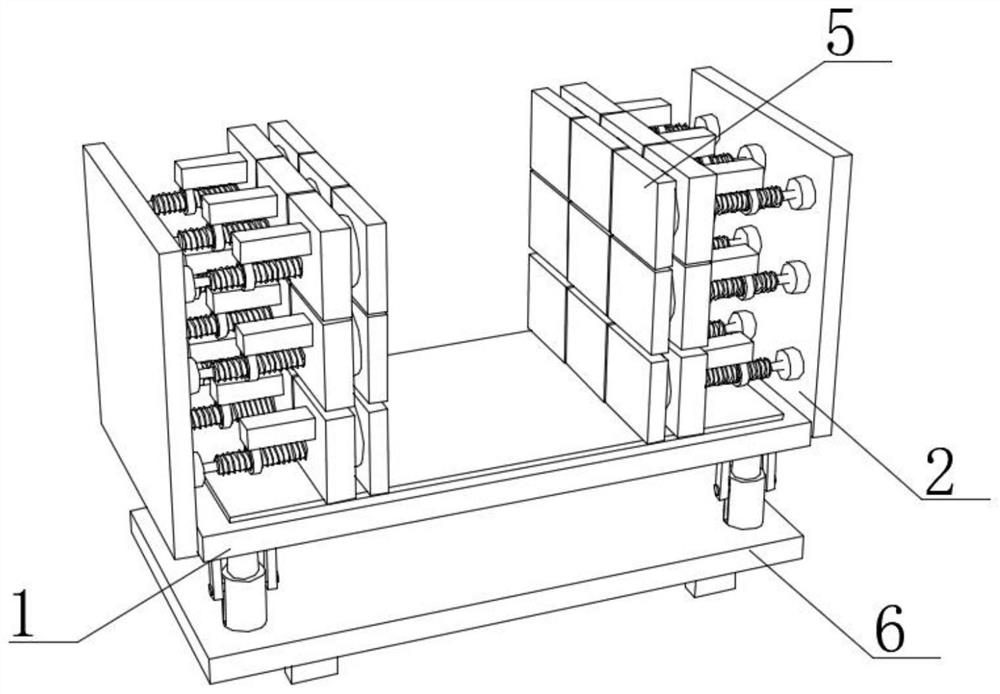

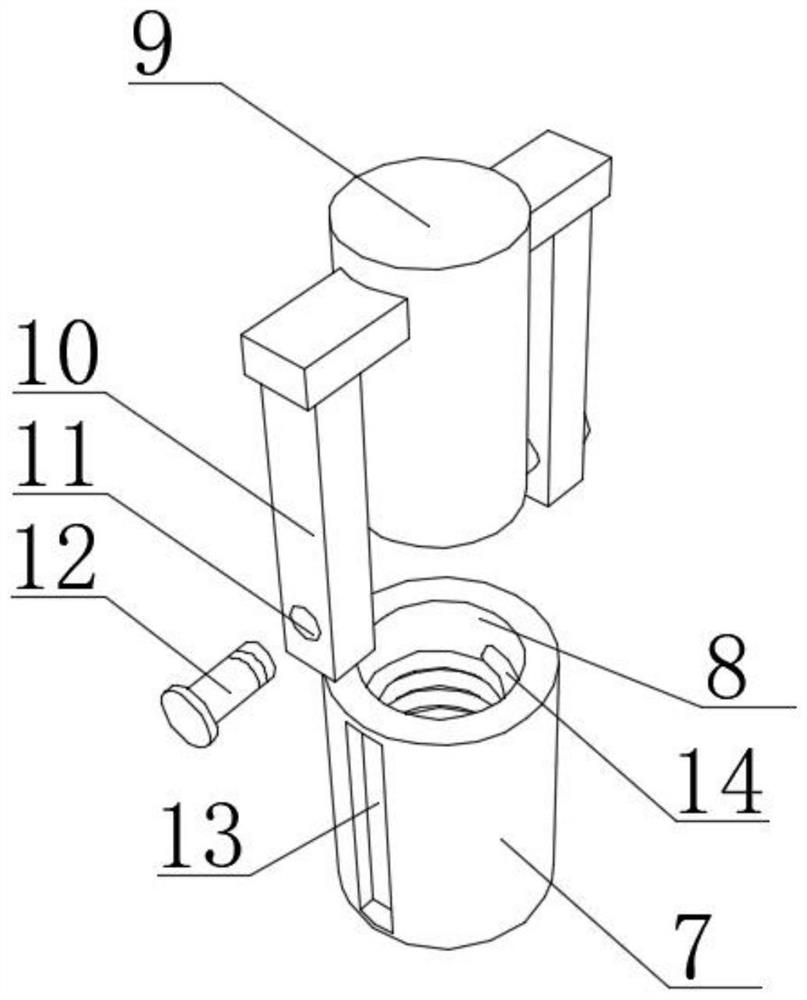

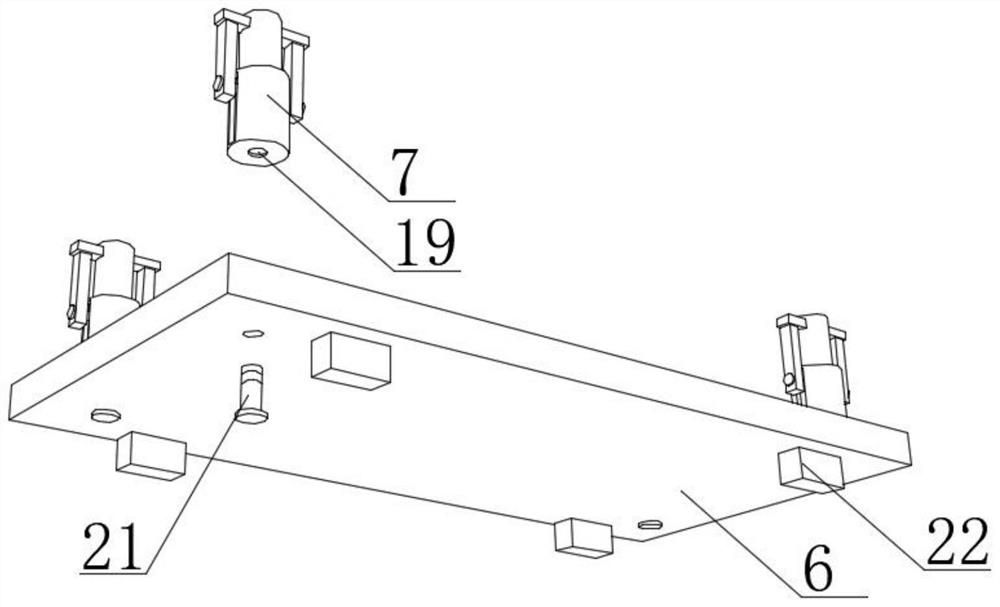

[0027] like Figure 1-4 As shown, the embodiment of the present invention provides a clamping device for smart furniture production, including a material supporting plate 1, the two ends of the material supporting plate 1 are vertically fixed with a fixing plate 2, and one end of the fixing plate 2 is horizontal An inner plate 3 is slidingly arranged, and an outer plate 5 is arranged on the outer side of the inner plate 3. A pressure sensor 4 is arranged between the inner end of the outer plate 5 and the outer end of the inner plate 3. The material of the outer plate 5 is soft rubber, and the material The lower end of the supporting plate 1 is provided with a bottom fixed tube 7 and a buffer and shock absorbing rod 9, the buffer and shock absorbing rod 9 is arranged on the top of the bottom fixed tube 7, and the inside of the bottom fixed tube 7 and the lower end of the buffer and shock absorbing rod 9 are arranged There is a spring 14, the lower side of the material supportin...

Embodiment 2

[0028] Embodiment two: a motor 15 is fixedly installed on one end of the fixed plate 2, a threaded screw 16 is connected on the output shaft of the motor 15, and a nut 17 is connected to the outer thread of the screw screw 16, and the upper end of the nut 17 is connected to one end of the inner plate 3 Connecting rod 18 is fixedly connected, and the lower end of lower plate 6 is provided with four anti-skid blocks 22, and motor 15 drives threaded screw mandrel 16 to rotate, and the threaded screw mandrel 16 that makes rotation can drive the nut 17 of outer end and connecting rod 18 to move horizontally, simultaneously The connecting rod 18 drives the inner plate 3 to move inwardly. At this time, the inner plate 3 drives the outer plate 5 and the pressure sensor 4 between them to move at the same time, so that the outer plate 5 can clamp the material, and the pressure sensor 4 performs force analysis at the same time. , if it is found that the current strength has reached the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com